Set up, Checking the oil – Harbor Freight Tools CENTRAL PNEAMATIC 95386 User Manual

Page 10

Page 10

For technical questions, please call 1-800-444-3353.

SKU 95386

Installing the air Filter

Figure 2

Cylinder Head (46)

Air Filter (45)

Thread the Air Filter (45) clockwise

onto the side of the Cylinder Head

(46).

Set up

Quick

coupler

Sample air line Setup

regulator with

Pressure Gauge

Quick

coupler

air Hose

on reel

Shut

off

Valve

Filter

oiler

coupler

Plug

tool

air

compressor

coupler

Plug

Figure 4

1. Connect a 1/4” NPT air hose to the

Quick Coupler (all sold separately).

The air hose must be long enough

to reach the work area with enough

extra length to allow free movement

while working.

Depending on the tool which you will

2.

be using with this compressor, you

may need to incorporate additional

components, such as an in-line oiler,

a filter, or a dryer (all sold separately).

Consult your air tool’s manual for

needed accessories.

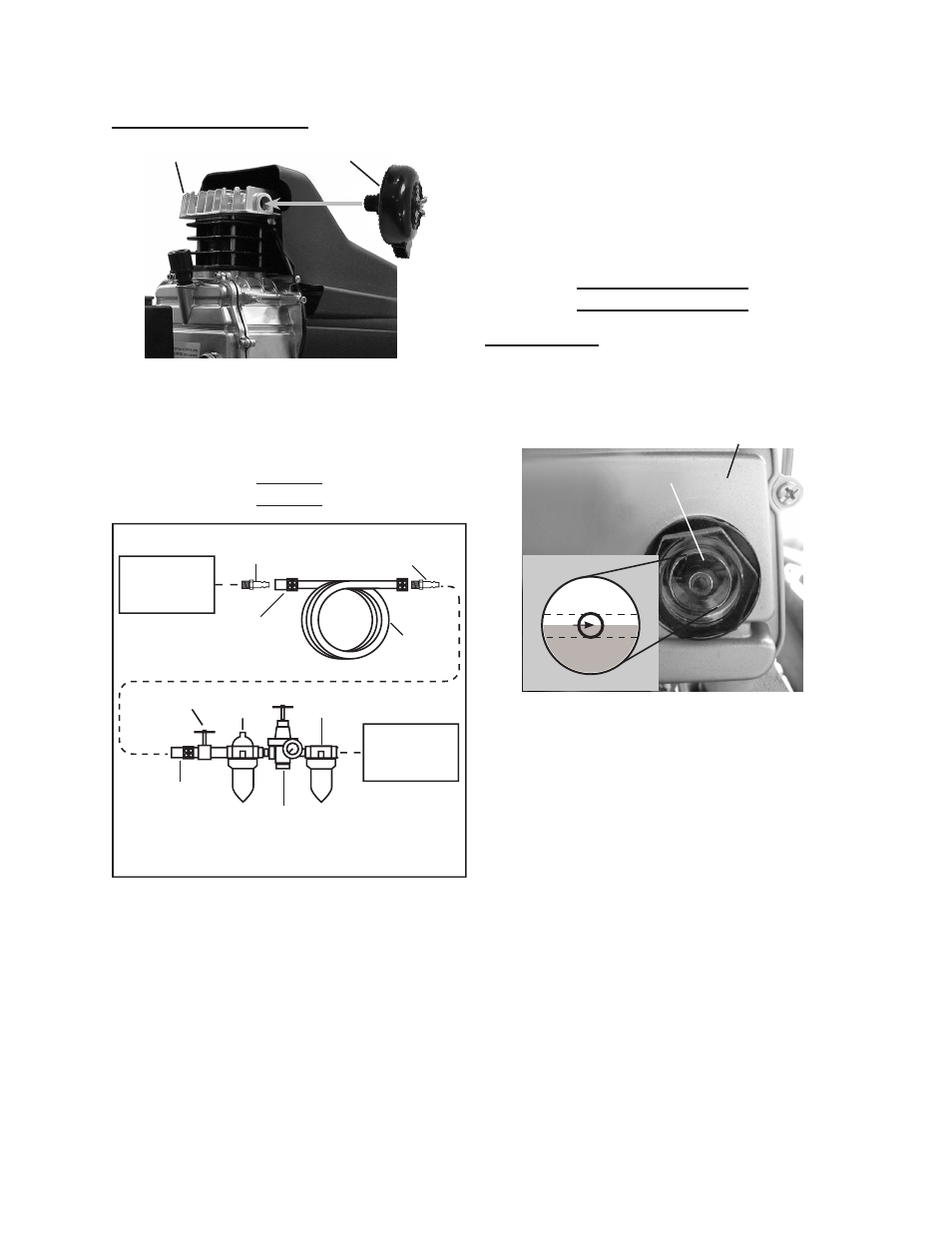

checking the oil

ImPortant: running the air

compressor with no oil or low

oil will cause damage to the

equipment and void the warranty.

Oil Sight Glass (33)

Crankcase Cover (32)

oVerFIll

loW

Full

OIL LEVEL

Figure 5

1. The oil level should be at the center

of the “full” level on the Oil Sight

Glass (33), as shown in Figure 5. Add

oil as needed to maintain this level.

Do not let the oil level go below the

center dot (LOW as shown in Figure

5) and do not overfill the oil so that it

is above the center dot (OVERFILL

as shown in Figure 5) on the sight

glass.

To add oil:

2.

Unthread the Oil Plug (31).

a.

Using a funnel to avoid spills,

b.

pour enough premium quality

SAE 30-weight, non-detergent, air

compressor oil (sold separately) into