7 faults; causes and remedies – HP 8-UB-1 User Manual

Page 27

UB USER INSTRUCTIONS ENGLISH 71569247 07-04

Page 27 of 32

®

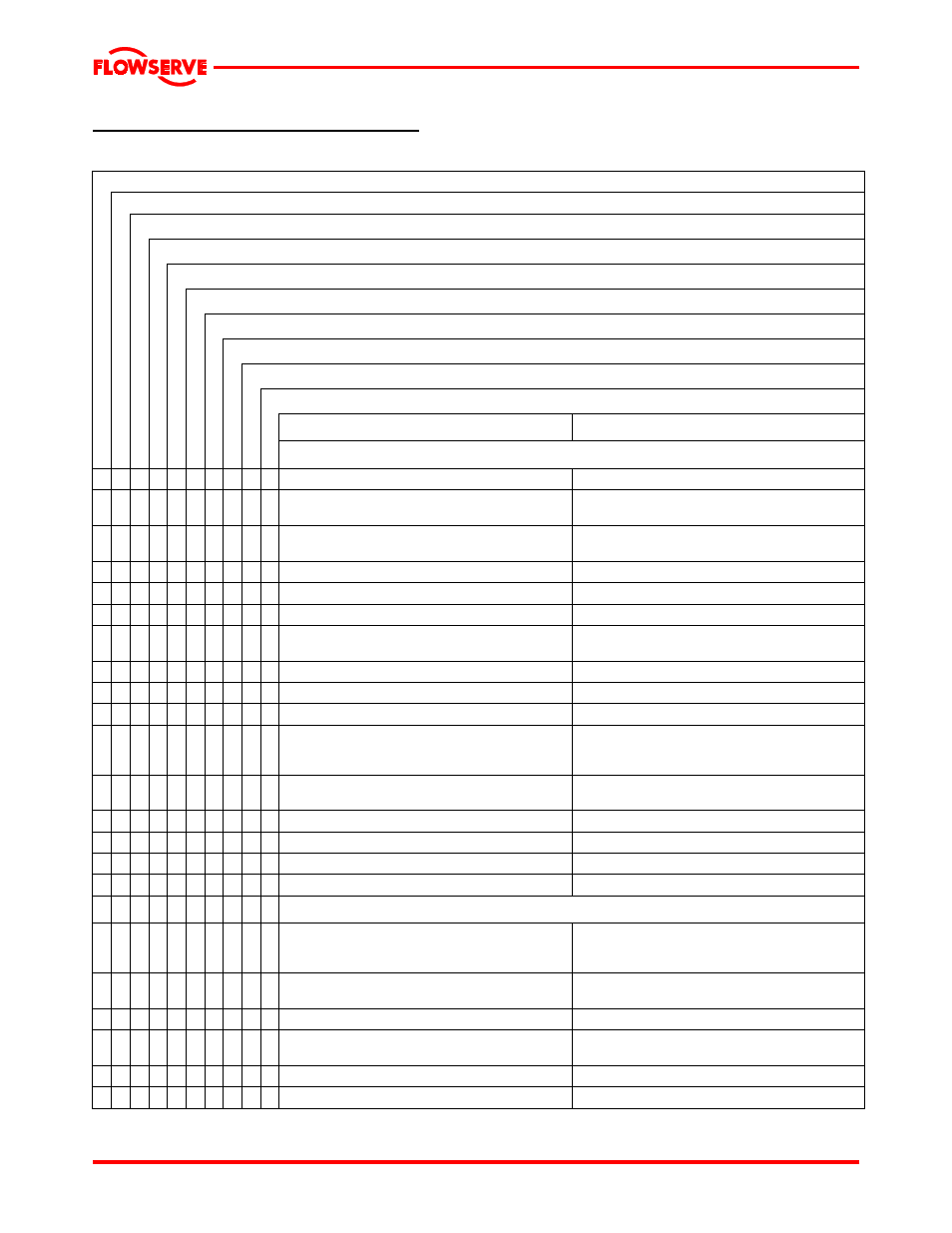

7 FAULTS; CAUSES AND REMEDIES

FAULT SYMPTOM

P u m p o v e r h e a t s a n d s e i z e s

⇓⇓⇓⇓

⇓⇓⇓⇓ Bearings have sh ort life

⇓⇓⇓⇓

⇓⇓⇓⇓ Pump vibrates or is nois y

⇓⇓⇓⇓

⇓⇓⇓⇓ M echanical seal has short life

⇓⇓⇓⇓

⇓⇓⇓⇓ M echanical seal leaks excessi vel y

⇓⇓⇓⇓

⇓⇓⇓⇓ Pump requires excessive power

⇓⇓⇓⇓

⇓⇓⇓⇓ Pump loses prime after star ting

⇓⇓⇓⇓

⇓⇓⇓⇓ Insuffi cien t pressure developed

⇓⇓⇓⇓

⇓⇓⇓⇓ Insuffi cien t cap aci t y delivered

⇓⇓⇓⇓

⇓⇓⇓⇓ Pump does not deliver liquid

⇓⇓⇓⇓

⇓⇓⇓⇓

PROBABLE CAUSES

POSSIBLE REMEDIES

A. SYSTEM TROUBLES

z

z

z

z

z

z

z

z

Pump not primed.

Check complete filling.

z

z

z

z

z

z

z

z

z

z

z

z z

z

z

z

Pump or suction pipe not completely filled with

liquid.

Check and complete filling.

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z z

z

z

z

Suction lift too high or level too low.

Check NPSH

A

>NPSH

R

, proper submergence,

losses at strainers and fittings.

z

z

z

z z

z

z

z z

z

z

z

Excessive amount of air or gas in liquid.

Check and purge from pipes.

z

z

z

z

z

z

z

z z

z

z

z

Air or vapour pocket in suction line.

Check suction line design for pockets.

z

z

z

z

z

z

z

z

Air leaks into suction line.

Check airtight pipe then joints and gaskets.

z

z

z

z

z

z

z

z

Air leaks into pump through mechanical seal,

sleeve joints, casing joint or pipe lugs.

Check airtight assembly then joints and gaskets.

z

z

z

z

z

z

z

z

Foot valve too small.

Investigate replacing the foot valve.

z

z

z

z

z

z

z

z

Foot valve partially clogged.

Clean foot valve.

z

z

z

z

z

z

z

z

z

z

z

z z

z

z

z

Inlet of suction pipe insufficiently submerged.

Check cut out system design.

z

z

z

z z

z

z

z z

z

z

z

Total head of system higher than differential head

of pump.

Check discharge head and head losses in

discharge pipe at the valve settings. Check back

pressure is not too high.

z

z

z

z

Total head of system lower than pump design

head.

Throttle at discharge valve or ask Flowserve if the

impeller can be trimmed.

z

z

z

z

Specific gravity of liquid different from design.

Consult Flowserve.

z

z

z

z

z

z

z

z z

z

z

z

Viscosity of liquid differs from design.

Consult Flowserve.

z

z

z

z

z

z

z

z

Operation at very low capacity.

Measure value and check minimum permitted.

z

z

z

z z

z

z

z

z

z

z

z

Operation at high capacity.

Measure value and check maximum permitted.

B. MECHANICAL TROUBLES

z

z

z

z z

z

z

z z

z

z

z z

z

z

z z

z

z

z z

z

z

z

Misalignment due to pipe strain.

Check the flange connections and eliminate

strains using elastic couplings or a method

permitted.

z

z

z

z

Improperly designed foundation.

Check setting of baseplate: tighten, adjust, grout

base as required.

z

z

z

z z

z

z

z z

z

z

z z

z

z

z z

z

z

z

Shaft bent.

Check shaft runouts within acceptable values.

z

z

z

z z

z

z

z z

z

z

z

z

z

z

z

Rotating part rubbing on stationary part internally.

Check for signs of this and consult Flowserve if

necessary.

z

z

z

z z

z

z

z z

z

z

z z

z

z

z z

z

z

z z

z

z

z

Bearings worn

Replace bearings.

z

z

z

z

z

z

z

z z

z

z

z

Wearing ring surfaces worn.

Replace worn wear ring/surfaces.