2 suction piping – HP 8-UB-1 User Manual

Page 14

UB USER INSTRUCTIONS ENGLISH 71569247 07-04

Page 14 of 32

®

• Prevent excessive external pipe load

• Never draw piping into place by applying force to

pump flange connections

• Do not mount expansion joints so that their force,

due to internal pressure, acts on the pump flange

The table in 4.5.3 summarizes the maximum forces

and moments allowed on horizontal shaft pump

casings.

Ensure piping and fittings are flushed

before use.

Ensure piping for hazardous liquids is arranged

to allow pump flushing before removal of the pump.

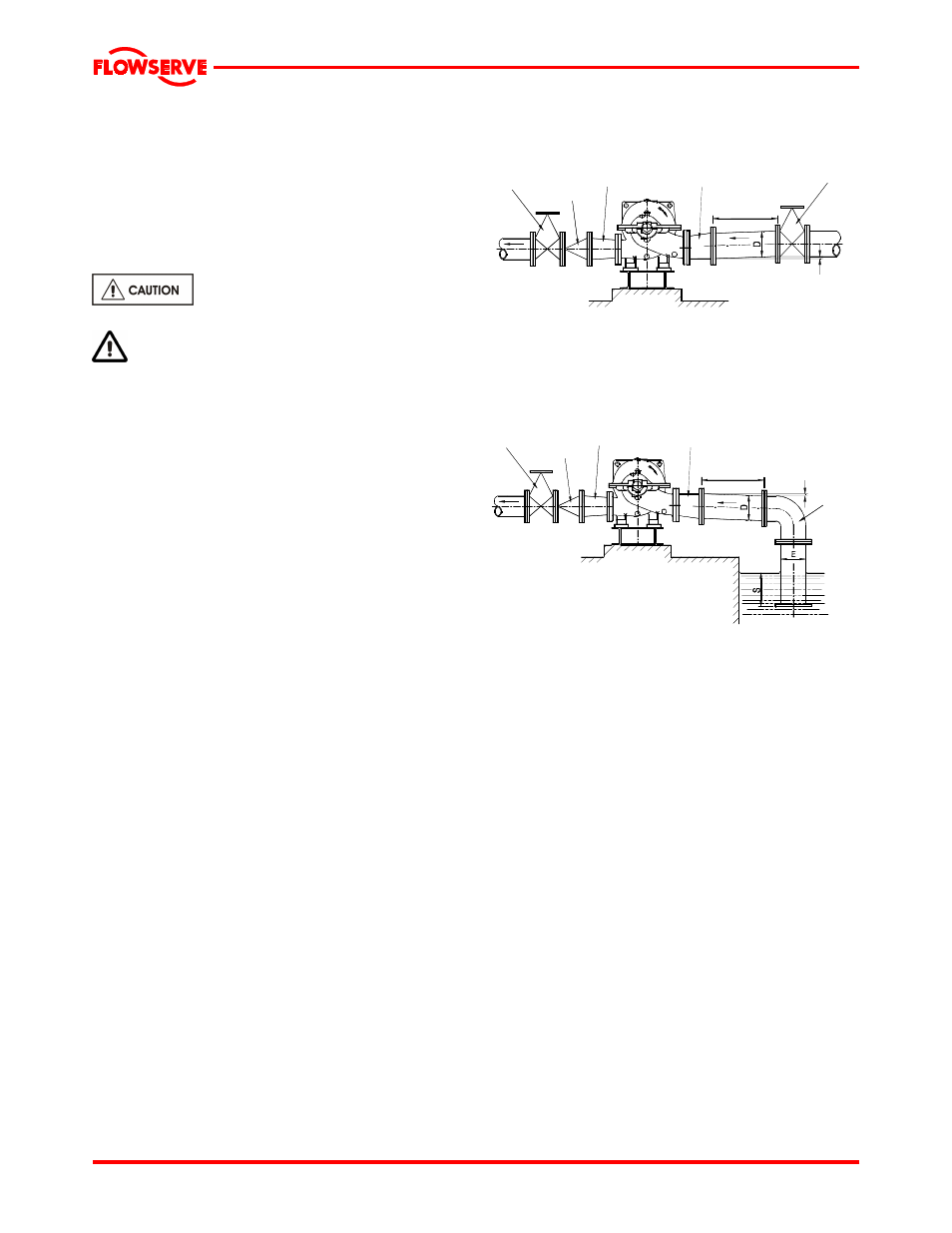

4.5.2 Suction piping

a) The inlet pipe should be one or two sizes larger

than the pump inlet bore and pipe bends should

be as large a radius as possible.

b) Pipework reducers should be conical and have a

maximum total angle of divergence of 15 degrees.

c) On suction lift the piping should be inclined up

towards the pump inlet with eccentric reducers

incorporated to prevent air locks.

d) On positive suction, the inlet piping must have a

constant fall towards the pump.

e) Flow should enter the pump suction with uniform

flow, to minimize noise and wear. This is

particularly important on large or high-speed

pumps, which should have a minimum of five

diameters of straight pipe on the pump suction

between the elbow and inlet flange. See section

10.3, Reference 1, for more detail.

f) Inlet strainers, when used, should have a net `free

area' of at least three times the inlet pipe area.

g) Do not install elbows at an angle other than

perpendicular to the shaft axis. Elbows parallel

to the shaft axis will cause uneven flow.

h) Except in unusual circumstances strainers are

not recommended in inlet piping. If considerable

foreign matter is expected a screen installed at

the entrance to the wet well is preferable.

i) Fitting an isolation valve will allow easier

maintenance.

j) Never throttle pump on suction side and never

place a valve directly on the pump inlet nozzle.

Typical design – flooded suction

Note:

Ideally reducers should be limited to one pipe diameter change,

ie 150 mm (6 in.) to 200 mm (8 in.). Must have a maximum total

angle of divergence of 15 degrees.

Typical design – suction lift

Notes:

1. S = Minimum submergence >3E.

2. Ideally reducers to be limited to one pipe diameter change,

ie 150 mm (6 in.) to 200 mm (8 in.). Must have a maximum

total angle of

divergence of 15 degrees.

Non

return

valve

Concentric

conical

reducer

Eccentric

conical

reducer

>5D

Discharge

isolating

valve

Suction

isolating

valve

Slope up from

pump suction

Discharge

isolating

valve

Non

return

valve

Concentric

conical

reducer

Eccentric

conical

reducer

>5D

Long

radius

bend

Slope down

from pump

suction