5 tools required, 6 fastener torques, 7 renewal clearances – HP 8-UB-1 User Manual

Page 23: 8 disassembly

UB USER INSTRUCTIONS ENGLISH 71569247 07-04

Page 23 of 32

®

1 – impeller

1 – diaphragm bush

(optional: 2 - mechanical seals

2 - impeller wear rings)

6.5 Tools required

A typical range of tools that will be required to

maintain these pumps is listed below.

Readily available in standard tool kits, and dependent

on pump size:

• Open ended spanners (wrenches) to suit up to

M 24 (

7

/

8

in.) screws/nuts

• Socket spanners (wrenches), up to M 24 (

7

/

8

in.)

screws

• Allen keys, up to 6 mm (¼ in.) A/F

• Range of screwdrivers

• Soft

mallet

More specialized equipment:

• Bearing

pullers

• Bearing induction heater

• Dial

test

indicator

• C-spanner (wrench) - for removing shaft nut.

(If difficulties in sourcing are encountered, consult

Flowserve.)

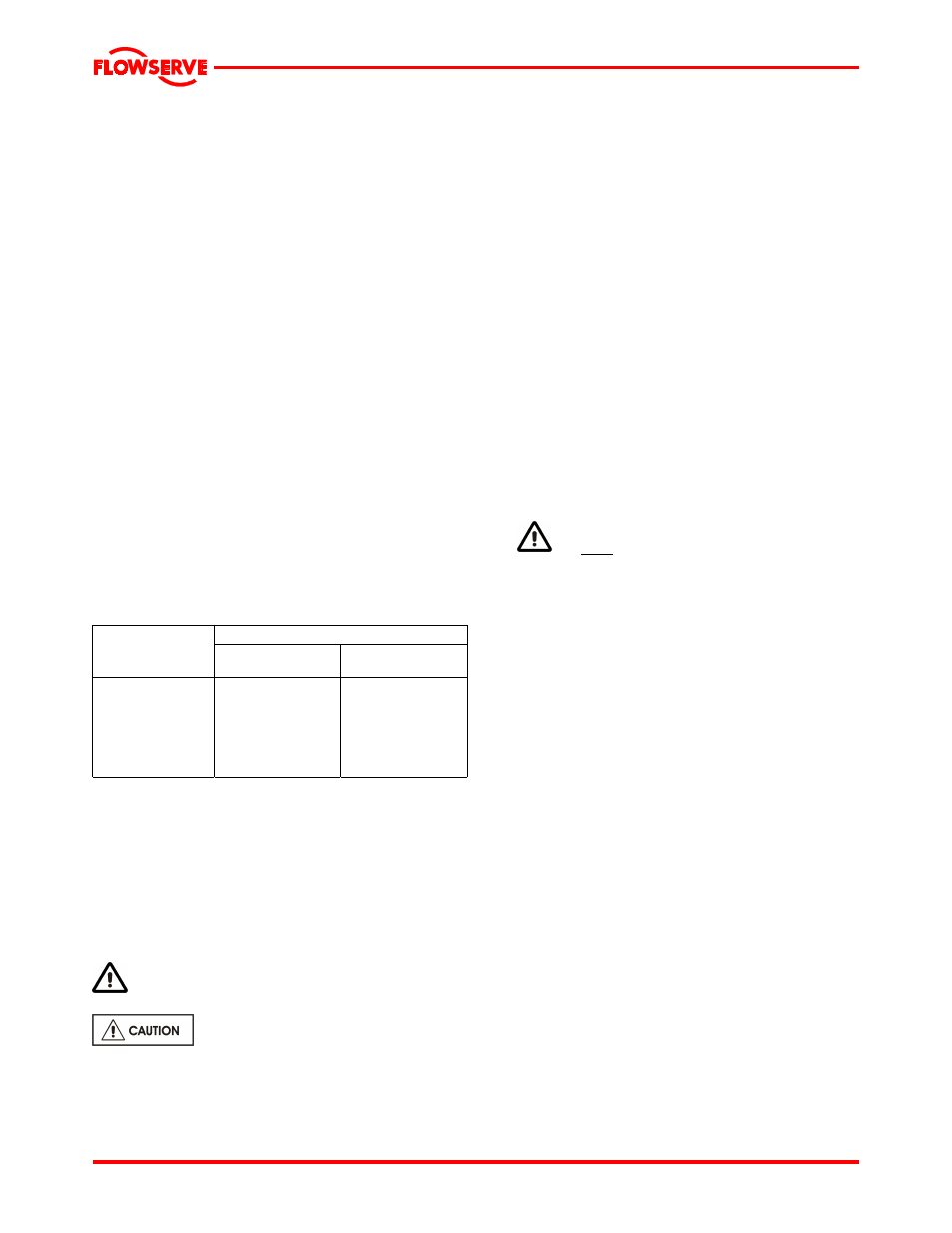

6.6 Fastener torques

Torque Nm (lbf·ft)

Bolt size

Pump feet

fasteners

All other

fasteners

M8 (

5

/

16

in.)

M10 (⅜ in.)

M12 (½ in.)

M16 (⅝ in.)

M20 (¾ in.)

M24 (⅞ in.)

-

-

63 (46)

170 (125)

340 (250)

590 (435)

10 (7)

20 (15)

34 (25)

84 (62)

165 (120)

285 (210)

6.7 Renewal clearances

As wear takes place between the impeller, casing ring

and diaphragm bush the overall efficiency of the pump

set will decrease. To maintain optimum efficiency it is

recommended that rings and bush are replaced and the

impeller renovated when the radial clearance detailed in

section 3.4.2 has doubled.

6.8 Disassembly

Refer to section 1.6, Safety, before dismantling

the pump.

Before dismantling the pump for

overhaul, ensure genuine Flowserve replacement

parts are available.

To dismantle the pump consult the sectional

drawings. See section 8, Parts lists and drawings.

a) Isolate motor and lock off electrical supply in

accordance with local regulations.

b) Isolate suction and discharge valves.

c) Remove coupling guards and disconnect the

coupling halves.

d) Drain pump casing. Remove any auxiliary piping

if applicable.

e) Release the copper lockwasher securing the

coupling nut and remove the pump half coupling.

f) Unbolt the glands/seal covers from the casing.

If glands are split type, remove completely.

g) With a suitable punch, drive out the two locating

dowels which are used on the horizontal split

flange to align the upper and lower half casings.

h) Remove the bolts, which hold the upper and lower

half of the casing together, and remove the upper

half. Tapped holes are provided in the joint flange

to enable the use of forcing bolts to loosen the joint.

i) Lift the casing upper half using the two eye bolts

provided.

Do NOT use this method to lift the bottom

half or complete pump casing.

j) Remove the 6 – screws securing each bearing

bracket to the bottom half casing.

k) Lift out rotor assembly. Use care in slinging,

handling and supporting of the rotor for

subsequent dismantling. Place rotor securely on

two support blocks.

l) When removing the rotor assembly, the casing rings

and diaphragm plate will be loosely attached to the

rotor.

m) Remove bearing covers and slide bearing housings

off bearings.

n) Release the copper lockwasher securing the

bearing locknut at the non-drive end and remove the

locknut. Pull off both ball bearings using a suitable

puller; ensuring force is applied to inner race only.

Retain the bearing distance pieces and coupling

distance piece for future use. Remove the bearing

covers.

o) Depending on configuration remove glands/seal

covers, packing and lantern ring/mechanical seal.

Refer to any special instructions supplied

with the mechanical seal.

p) Remove the two socket head screws securing

each shaft sleeve nut. Using C-spanner remove

shaft nuts. Slide off shaft sleeves.