4 discharge piping, 5 auxiliary piping, 1 drains – HP 8-UB-1 User Manual

Page 15: 2 pumps fitted with packed gland, 3 pumps fitted with mechanical seals

UB USER INSTRUCTIONS ENGLISH 71569247 07-04

Page 15 of 32

®

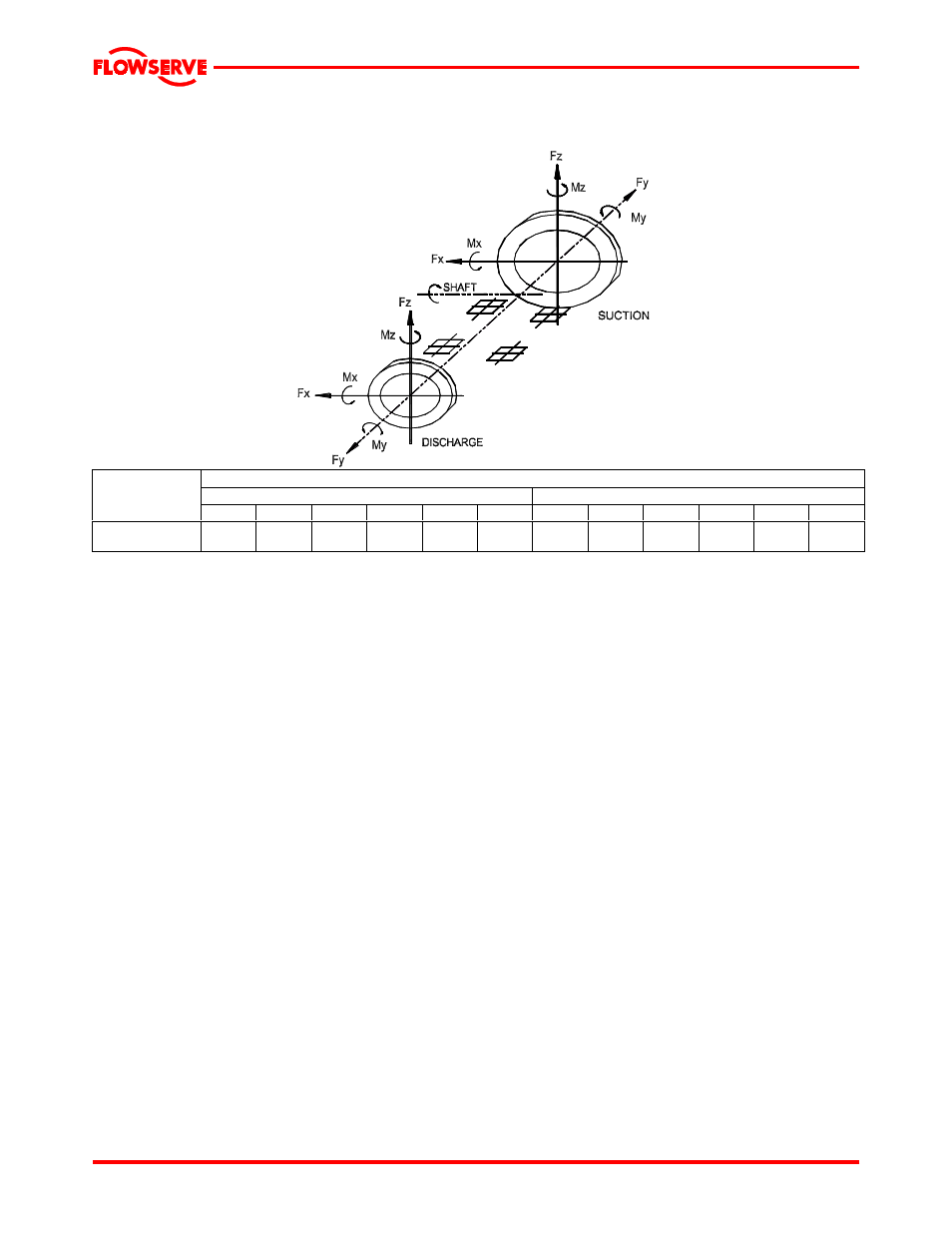

4.5.3 Maximum forces and moments allowed on the pump suction and discharge flanges of horizontal

shaft pumps

Maximum forces (F) in kN (lbf) and maximum moments (M) in kNm (lbf·ft)

Suction

Discharge

Type and size

Fx

Fy

Fz

Mx

My

Mz

Fx

Fy

Fz

Mx

My

Mz

8-UB-1

7.35

(1653)

5.78

(1299)

4.20

(944)

4.25

(3134)

2.25

(1659)

3.00

(2212)

3.84

(863)

4.40

(989)

3.20

(719)

2.20

(1622)

1.20

(885)

1.60

(1180)

Notes:

1) F = External force (tension or compression).

M = External moment, clockwise or counter-clockwise.

2) Forces and moments may be applied simultaneously in any

direction.

3) Values apply to all materials.

4) Higher loads may be applicable, if direction and magnitude of

individual loads are known, but these need written approval

from Flowserve Pumps.

5) Pumps must be on rigid foundations and baseplates must be

fully grouted

6) Pump/baseplate should not be used as pipe anchor. Suction

and discharge piping should be anchored as close as possible

to the pump flanges to reduce vibration and prevent strain on

the pump casing. Expansion joints are recommended. They

must be properly tied and located on the side of the pipe anchor

away from the pump.

7) The pump mounting bolt torques specified must be used to

prevent relative movement between the pump casing and

baseplate. (See section 6.6, Fastener torques.) The bolt

material must have a minimum yield strength of 600 N/mm

2

(87 000 lb/in.

2

).

4.5.4 Discharge piping

See section 4.5.2 for typical pipework design.

A non-return valve should be located in the discharge

pipework to protect the pump from excessive back

pressure and hence reverse rotation when the unit is

stopped.

Pipework reducers should have a maximum total

angle of divergence of 9 degrees.

Fitting an isolation valve will allow easier maintenance.

4.5.5 Auxiliary piping

4.5.5.1 Drains

Pipe pump casing drains and gland leakage to a

convenient disposal point.

4.5.5.2 Pumps fitted with packed gland

When suction pressure is below ambient pressure it

is necessary to feed the gland packing with liquid to

provide lubrication and prevent the ingress of air.

This is normally achieved with a supply from the

pump discharge volute to the stuffing box.

If the pumped liquid is dirty and cannot be used for

sealing, a separate clean compatible liquid supply to

the gland at 1 bar (15 psi) above suction pressure is

recommended.

4.5.5.3 Pumps fitted with mechanical seals

Single seals requiring re-circulation will normally be

provided with the auxiliary piping from pump casing

already fitted.

If the seal requires an auxiliary quench then a

connection must be made to a suitable source of

liquid flow, low pressure steam or static pressure from

a header tank. Recommended pressure is 0.35 bar

(5 psi) or less. Check General arrangement drawing.