Table 1-2, Calibration components -17, Oxymitter 4000 – Emerson OXYMITTER 4000 User Manual

Page 53: Instruction manual

Instruction Manual

IB-106-340 Rev. 3.0

December 2003

Rosemount Analytical Inc. A Division of Emerson Process Management

Description and Specifications 1-17

Oxymitter 4000

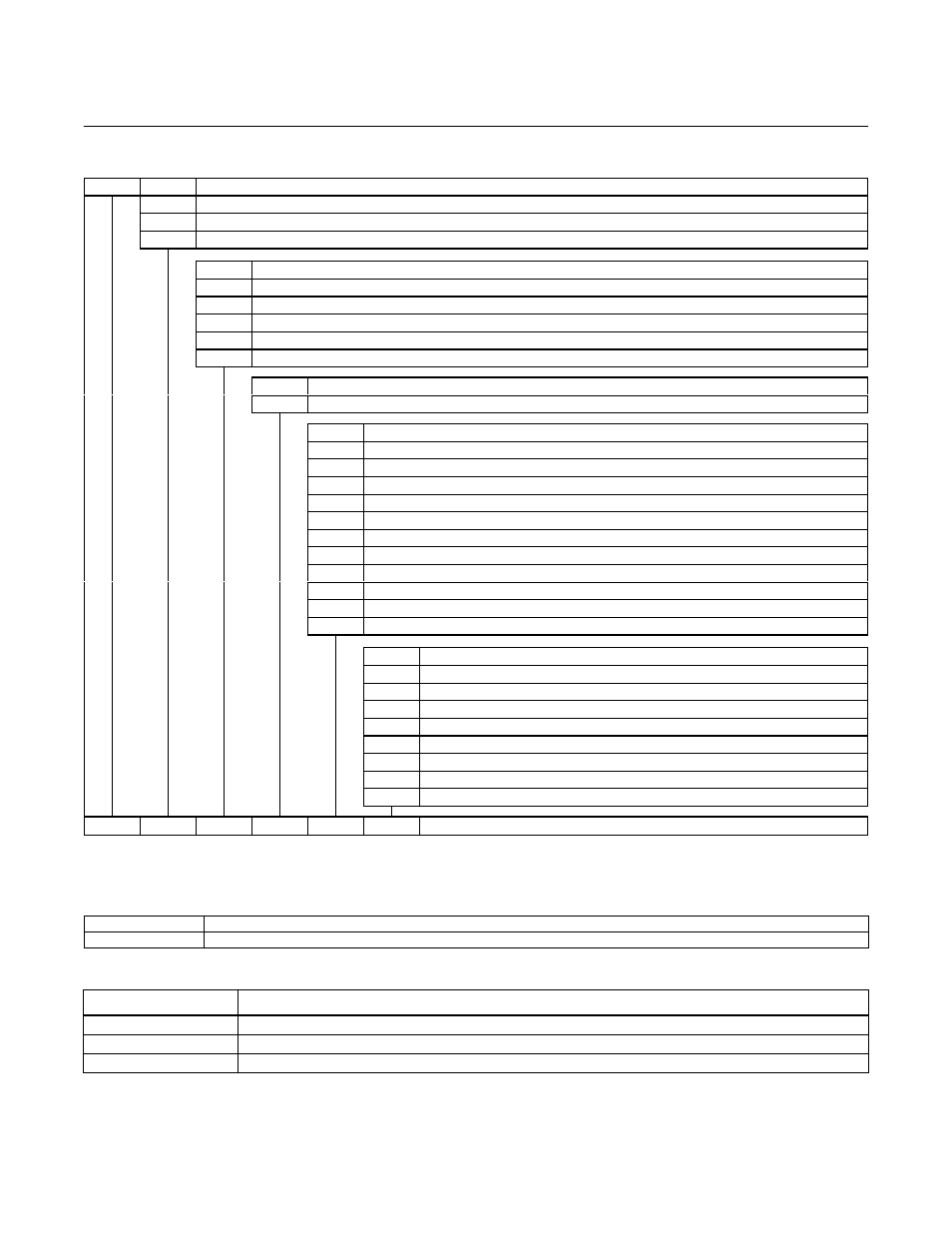

Table 1-1. Product Matrix (Continued)

Cont’d

Code

Communications

1

HART with Membrane Keypad, blind cover

2

HART with Membrane Keypad, glass cover

3

HART with Local Operator Interface, glass cover, English only

Code

Language

1

English

2

German

3

French

4

Spanish

5

Italian

Code

Filtered Customer Termination

00

Specified as Part of Electronics Housing

Code

Calibration Accessories

00

No Hardware

01

Calibration Gas Flowmeter and Reference Air Set

02

Intelligent Multiprobe Sequencer (Refer to Table 1-3)

03

Single Probe Sequencer, Horizontal Orientation, Brass/Teflon, no Reference Air Set

04

Single Probe Sequencer, Horizontal Orientation, Brass/Teflon, with Reference Air Set

05

Single Probe Sequencer, Horizontal Orientation, Stainless Steel, no Reference Air Set

06

Single Probe Sequencer, Horizontal Orientation, Stainless Steel, with Reference Air Set

07

Single Probe Sequencer, Vertical Orientation, Brass/Teflon, no Reference Air Set

08

Single Probe Sequencer, Vertical Orientation, Brass/Teflon, with Reference Air Set

09

Single Probe Sequencer, Vertical Orientation, Stainless Steel, no Reference Air Set

10

Single Probe Sequencer, Vertical Orientation, Stainless Steel, with Reference Air Set

Code

Electronics to Probe Cable Length

00

No Cable

10

20 ft (6 m) Cable

11

40 ft (12 m) Cable

12

60 ft (18 m) Cable

13

80 ft (24 m) Cable

14

100 ft (30 m) Cable

15

150 ft (45 m) Cable

16

200 ft (61 m) Cable

Cont’d

2

2

00

09

14

Example

NOTES:

(1)

Recommended usages: High velocity particulates in flue stream, installation within 11.5 ft (3.5 m) of soot blowers or heavy salt cake buildup.

Applications: Pulverized coal, recovery boilers, lime kiln. Regardless of application, abrasive shields with support brackets are recommended

for 9 ft (2.74 m), 12 ft (3.66 m), 15 ft (4.57 m), and 18 ft (5.49 m) probe installations, particularly horizontal installations.

(2)

Where possible, specify SPS number; otherwise, provide details of the existing mounting plate as follows:

Plate with studs

Bolt circle diameter, number, and arrangement of studs, stud thread, stud height above mounting plate.

Plate without studs

Bolt circle diameter, number, and arrangement of holes, thread, depth of stud mounting plate with accessories.

Table 1-2. Calibration Components

Part Number

Description

1A99119G01

Two disposable gas bottles — 0.4% and 8% O

2

, balance nitrogen — 550 liters each*

1A99119G02

Two flow regulators for calibration gas bottles

1A99119G03

Bottle rack

* Calibration gas bottles cannot be shipped via airfreight. When bottles are used with “CALIBRATION RECOMMENDED” features,

the bottles should provide 2 to 3 years of calibrations in normal service.