Instructional booklet, Caution, Notice – Eaton Electrical Magnum Transfer Switch User Manual

Page 17: Fixed and drawout magnum transfer switches

IB01602011E

For more information visit: www.Eaton.com

Instructional Booklet

Effective: March 2007

Page 17

Fixed and Drawout Magnum Transfer Switches

4.3 Unpackaging and Inspection

Proceed with the following four steps:

Step 1: Carefully uncrate the transfer switch. If damage is visible,

please contact your local Eaton sales representative or the

factory.

Step 2: Open the door and visually verify that there are no broken

or damaged components or evidence of distorted metal or

loose wires as a result of rough handling.

Step 3: A label on the door provides specifications for your trans-

fer switch. Verify that these specifications comply with

your requirements.

Step 4: Remove any braces or packing used to protect the trans-

fer switch or internal components during shipping.

4.4 Mounting Procedure

With the enclosed transfer switch equipment unpacked and ready

for mounting, proceed with the following steps:

Step 1: Mounting and cabling access is best provided by remov-

ing side and rear covers (when applicable). See Section

9.3 for cover removal instructions.

Step 2: Gently maneuver the switch into its location using all of

the supplied lift brackets.

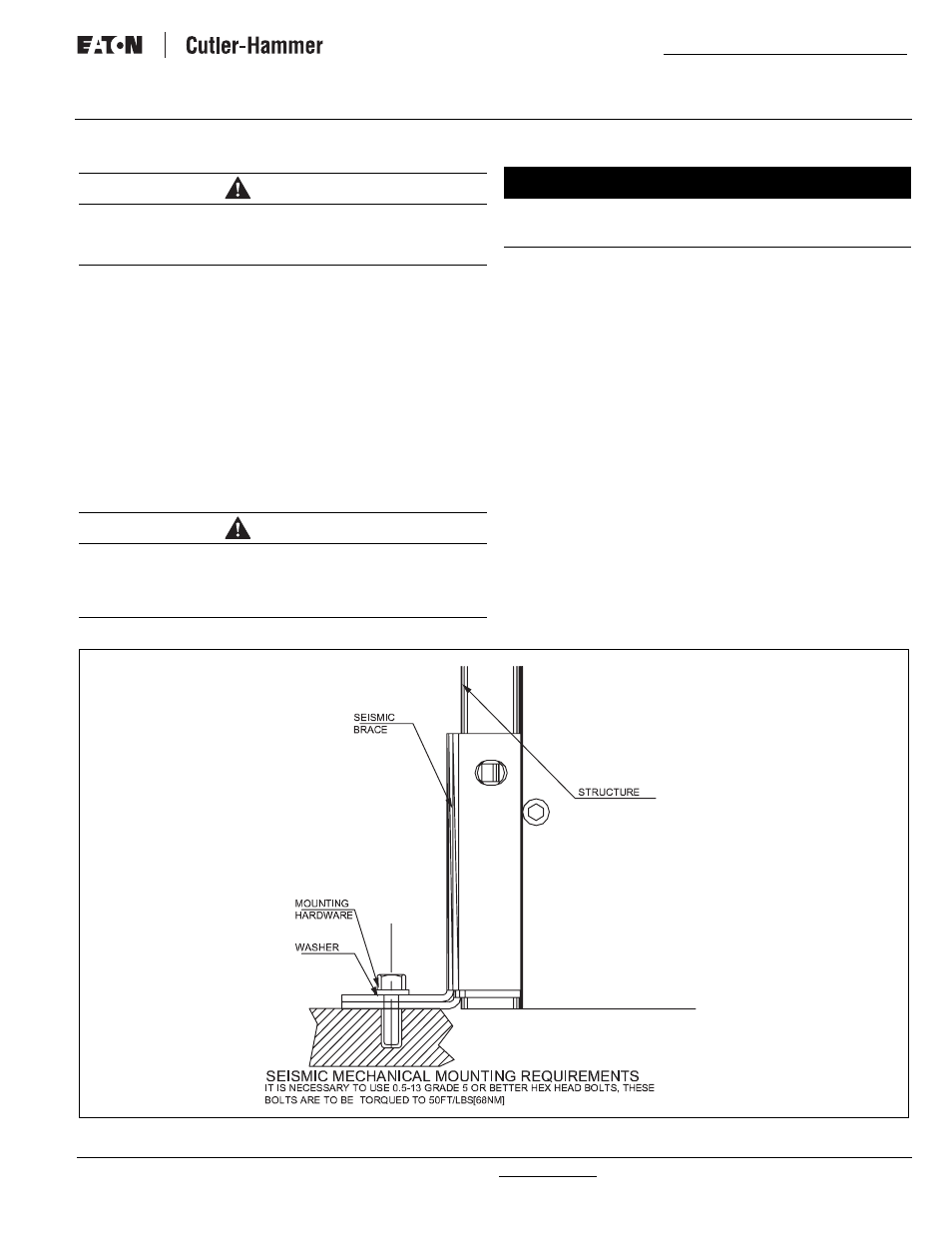

Step 3: Bolt the enclosure to the base. Use separate cleats

(Option 42 only) if Seismic Uniform Building Code (UBC)

Zone 4 certification is desired (Figure 20), and secure

with 1/2-13 UNC Grade 5 hex bolts.

Step 4: Tighten bolts to 50 ft-lbs (68 Nm).

Step 5: Double check to ensure that all packing and shipping

material has been removed

.

Figure 20. Seismic Tested and Approved Product Mounting Instructions.

CAUTION

SINCE THE ENCLOSED TRANSFER SWITCH MUST BE LIFTED INTO

PLACE FOR MOUNTING, BE CERTAIN THAT ADEQUATE RESOURCES

ARE AVAILABLE FOR LISTING TO AVOID PERSONNEL INJURIES OR

EQUIPMENT DAMAGE.

CAUTION

EXTREME CARE SHOULD BE TAKEN TO PROTECT THE TRANSFER

SWITCH FROM DRILL CHIPS, FILLINGS, AND OTHER CONTAMI-

NANTS WHEN MAKING THE CABLE ENTRY HOLES AND MOUNTING

THE ENCLOSURE TO PREVENT COMPONENT DAMAGE OR A

FUTURE MALFUNCTION.

NOTICE

CABLE ENTRY HOLES ARE NOT PART OF THE ENCLOSURE WHEN

SHIPPED FROM THE FACTORY AND MUST BE PROVIDED IN THE

FIELD, EITHER BEFORE OR AFTER MOUNTING THE ENCLOSURE.