Section 2: receiving, handling, and storage, Section 3: equipment description, Instructional booklet – Eaton Electrical Magnum Transfer Switch User Manual

Page 10: Fixed and drawout magnum transfer switches

For more information visit: www.Eaton.com

IB01602011E

Instructional Booklet

Page 10

Effective: March 2007

Fixed and Drawout Magnum Transfer Switches

Section 2: Receiving, Handling, and Storage

2.1 Receiving

Every effort is made to ensure that the transfer switch equipment

arrives at its destination undamaged and ready for installation.

Crating and packing is designed to protect internal components as

well as the enclosure. Transfer switch enclosures are skid

mounted and suited for fork lift movement. Care should be exer-

cised, however, to protect the equipment from impact at all times.

Do not remove the protective packaging until the equipment is at

the installation location and ready for installation.

When the transfer switch equipment reaches its destination, the

customer should inspect the shipping container for any obvious

signs of rough handling and/or external damage incurred during

transportation. Record any external and internal damage observed

for reporting to the transportation carrier and Eaton, once a thor-

ough inspection is completed. All claims should be as specific as

possible and include the Shop Order and General Order numbers.

A shipping label is affixed to the top of the shipping container

which includes a variety of equipment and customer information,

such as General Order Number (GO #) and Catalog Number

(Cat #). Make certain that this information matches other ship-

ping paper information.

Each transfer switch enclosure is bolted to a rigid wooden pallet.

The pallet is open at two ends for movement by a fork lift. The

shipment is secured and further protected with shrink wrap. Do

not discard the packing material until the equipment is ready for

installation.

A plastic bag of documents will be found within the enclosure,

usually attached to the inside of the door. Important documents,

such as test reports, wiring diagrams, and appropriate instruction

leaflets, are enclosed within the bag and should be filed in a safe

place.

2.2 Handling

As previously mentioned, the transfer switch equipment is pack-

aged for fork lift movement. Protect the equipment from impact

at all times and DO NOT double stack. Once the equipment is at

the installation location and ready for installation, the packaging

material can be removed. Once the enclosure is unbolted from the

wooden pallet, it can be installed using the lifting provision located

on the top of the structure. Be careful not to damage the top or

bottom enclosure mounting flanges. Refer to Section 4 of this

manual for specific installation instructions.

2.3 Storage

Although well packaged, this equipment is not suitable for storage

outdoors. The equipment warranty will not be applicable if there

is evidence of outdoor storage. If the equipment is to be stored

indoors for any period of time, it should be stored with its protec-

tive packaging material in place. Protect the equipment at all

times from excessive moisture, construction dirt, corrosive condi-

tions, and other contaminants.

It is strongly suggested that the package-protected equipment be

stored in a climate controlled environment of -20° to 85°C

(-4° to 185°F) with a relative humidity of 80% or less. DO NOT,

under any circumstances, stack other equipment on top of a trans-

fer switch equipment enclosure, whether packaged or not.

Section 3: Equipment Description

3.1 General

This Eaton transfer switch equipment is available in four different

configurations:

•

ATS (Closed and Open transition);

•

Non-Automatic (Electrically Operated) (Open Transition Only);

•

Bypass Isolation Transfer Switch (Open and Closed Transition);

and

•

Power Panel.

Refer to Section 1 for a discussion of all four types. Each transfer

switch is usually supplied in an enclosure, although unmounted

sub-assemblies can be supplied for mounting by the customer.

The enclosed ATS is the only specific type that will be discussed

in this section.

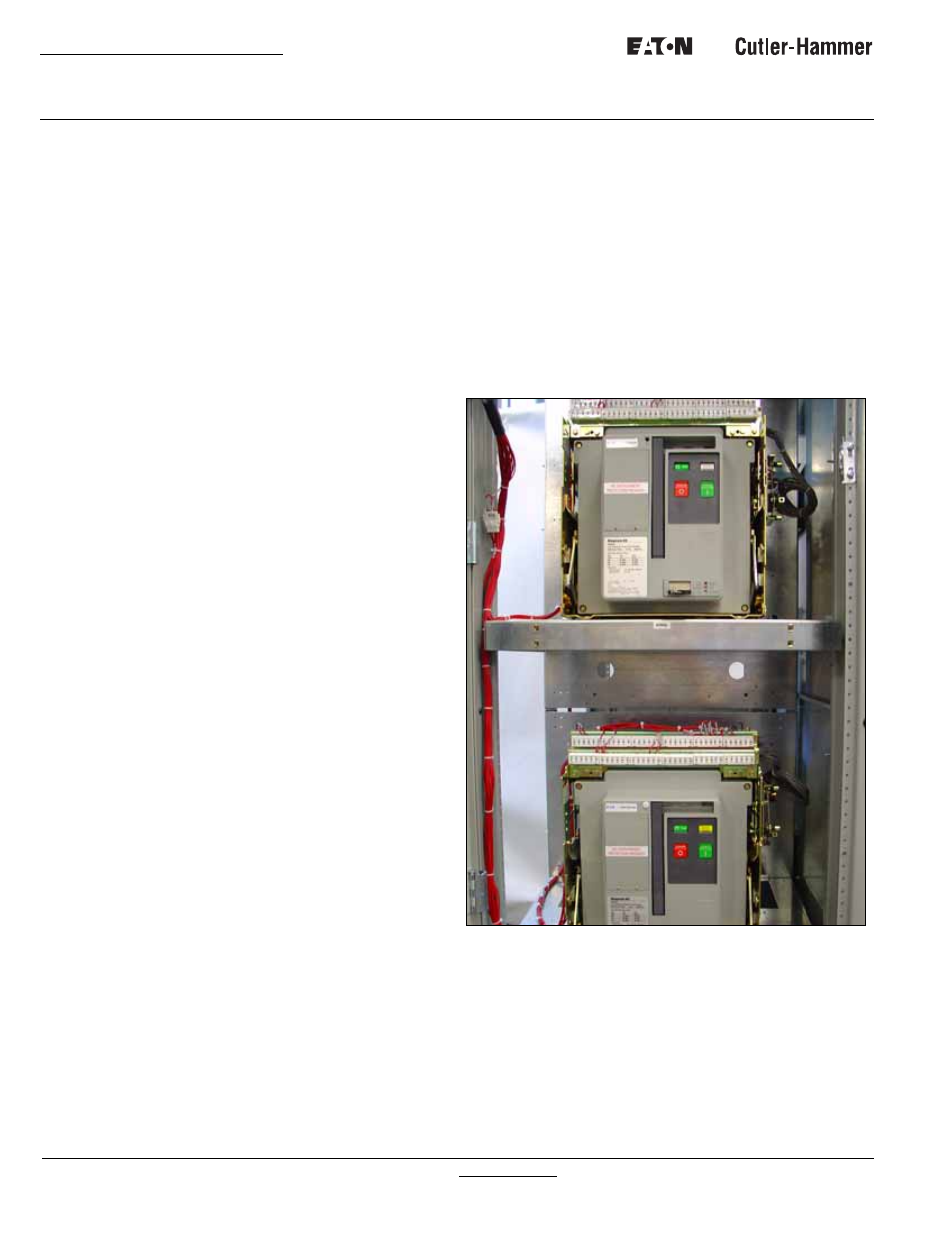

Figure 11. Typical Power Panel (Open Transition Shown).

The enclosed ATS consists of three basic panels interconnected

through connector plugs and mounted in an enclosure:

•

Power Panel;

•

Voltage Selection Panel; and

•

Logic Panel

•

ATC-600 (open transition only)

•

ATC-800 (closed transition only).