Installation of appliance, Initial installation – Enviro C-11366 User Manual

Page 17

Initial Installation

QUALIFIED INSTALLERS ONLY

I

NSTALLATION

OF

A

PPLIANCE

:

Sealant

Female

Locking

Lugs

Male

Locking

Lugs

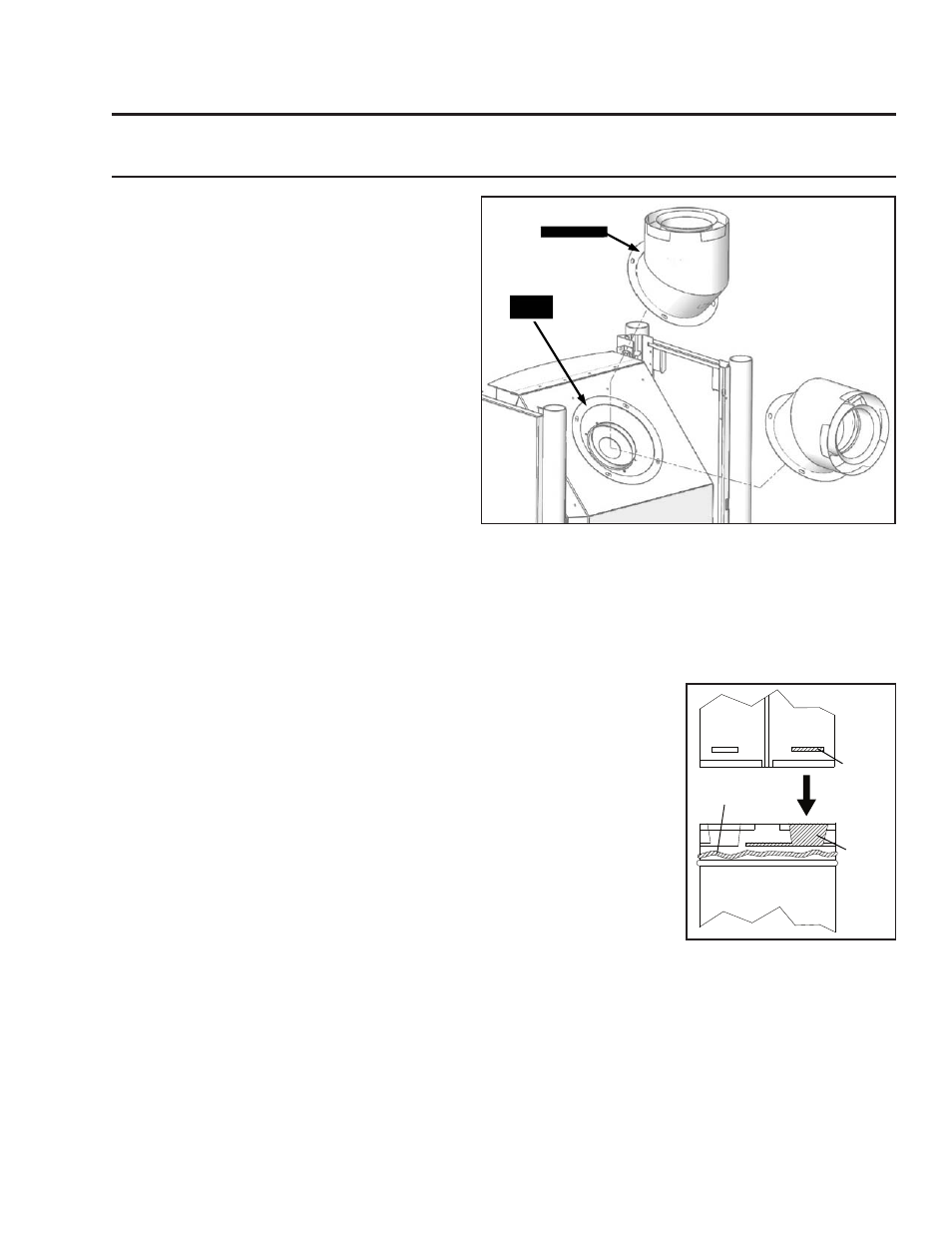

Figure 26: Twist-Lock

Connection.

- PO512-54 DMS). Refer to M

AINTENANCE

A

ND

S

ERVICE

- F

UEL

C

ONVERSION

.

3. Set the appliance in the desired location. Check to determine if wall studs are in the way when the

venting system is attached. If this is the case, you may want to adjust the location of the appliance.

4. Direct vent pipe and fittings are designed with special twist-lock connections. Assemble the desired

combination of black pipe and elbows to the appliance adapter with pipe seams oriented towards the

wall or floor, as much out of view as possible.

17

Figure 25: Converting Top Vented into Rear Vented.

1. This unit has been shipped as a top-vented

freestanding unit and must be converted to a

rear vented unit before installed.

a. Carefully remove the trivet and the stovetop.

Place on a soft surface as not to damage the

finish.

b. Remove the four (4) 1⁄4” screws that hold the

flue collar elbow to the unit body.

c. Carefully remove the elbow being sure not to

damage the gasket that is glued to the flue

collar elbow, it seals the flue to the firebox

(see Figure 25).

d. Turn the elbow 180° to the rear vent position

and re-fasten with the screws removed in

step b.

2. This unit has been shipped with a Cara

orifice installed and it must be replaced with

a Cara DR orifice (NG - PO512-42 DMS or LP

Place a bead of Mil-Pac on the outer edge of the inner exhaust pipe

(non-flared end). Place a bead of high temperature silicone on the male

edge of the outer pipe. Push the pipe sections completely together, then

twist-lock one section clockwise approximately 1⁄4 turn, until the two (2)

sections are fully locked. The female locking lugs will not be visible from

the outside, on black pipe. They may be located by examining the inside

of the female ends as shown in Figure 26.

Notes:

(a) Twist-lock procedure: four (4) indentations, located on the female end

of the pipes and fittings, are designed to slide straight onto the male ends

of adjacent pipes and fittings, by orienting the four (4) pipe indentations so

they match and slide into the four (4) entry slots on the male end.

(b) Pipe minimum clearances to combustibles must be maintained; 2”

(51mm) at top, 11⁄2” (38mm) at sides, 11⁄2” (38mm) at bottom.

3. With the pipe attached to the stove in the correct location, mark the wall for a 10” (25.4cm) x 10”

(25.4 cm) square hole (refer to Figure 27). The center of the square hole should match the center line

of the horizontal pipe. Cut and frame the 10” (25.4cm) x 10” (25.4cm) hole in the exterior wall where

the vent will be terminated. Refer to Figure 24 and Table 7. If the wall being penetrated is constructed

of non-combustible material i.e. masonry or concrete, a 7” (17.8cm) hole is acceptable.

4. Position the horizontal vent termination in the center of the 10” (25.4cm) x 10” (25.4cm) hole, and

attach to the exterior wall with the four (4) screws provided. Before attaching the vent termination to

the exterior wall, run a bead of non-hardening mastic around the edges, so as to make a seal between