Ground the flowmeter components, 5 ground the flowmeter components – Emerson MICRO MOTION 1700 User Manual

Page 30

10.

Turn the display cover clockwise until it is snug.

11.

Replace the end-cap clamp by reinserting and tightening the cap screw.

12.

Restore power to the transmitter.

3.5

Ground the flowmeter components

In 4-wire remote installations, the transmitter and sensor are grounded separately.

CAUTION!

Improper grounding could cause inaccurate measurements or flow meter failure. Failure to

comply with requirements for intrinsic safety in a hazardous area could result in an explosion.

Note

For hazardous area installations in Europe, refer to standard EN 60079-14 or national standards.

If national standards are not in effect, adhere to the following guidelines for grounding:

•

Use copper wire, 14 AWG (2.5 mm

2

) or larger wire size.

•

Keep all ground leads as short as possible, less than 1

Ω impedance.

•

Connect ground leads directly to earth, or follow plant standards.

1.

Ground the sensor according to the instructions in the sensor documentation.

2.

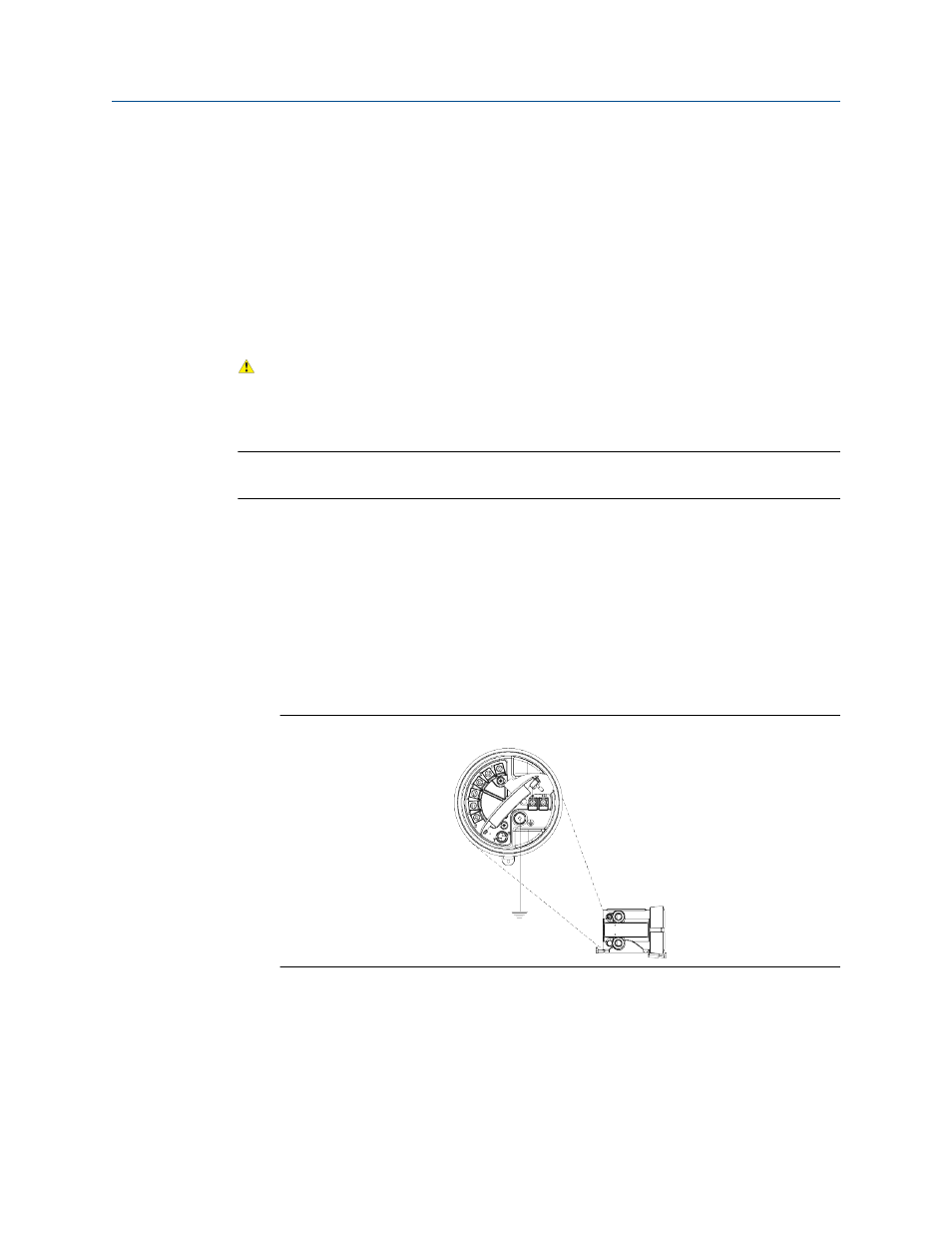

Ground the transmitter according to applicable local standards, using the

transmitter’s internal or external ground screw.

Transmitter internal grounding screw

Figure 3-10:

Mounting and sensor wiring for 4-wire remote installations

26

Micro Motion

®

Model 1700 and 2700