Ground the flowmeter components, 6 ground the flowmeter components – Emerson MICRO MOTION 1700 User Manual

Page 51

10.

Turn the display cover clockwise until it is snug.

11.

Replace the end-cap clamp by reinserting and tightening the cap screw.

12.

Restore power to the transmitter.

4.6

Ground the flowmeter components

In 9-wire remote installations, the transmitter/core processor assembly and sensor are

grounded separately.

CAUTION!

Improper grounding could cause inaccurate measurements or flow meter failure. Failure to

comply with requirements for intrinsic safety in a hazardous area could result in an explosion.

Note

For hazardous area installations in Europe, refer to standard EN 60079-14 or national standards.

If national standards are not in effect, adhere to the following guidelines for grounding:

•

Use copper wire, 14 AWG (2.5 mm

2

) or larger wire size.

•

Keep all ground leads as short as possible, less than 1

Ω impedance.

•

Connect ground leads directly to earth, or follow plant standards.

1.

Ground the sensor according to the instructions in the sensor documentation.

2.

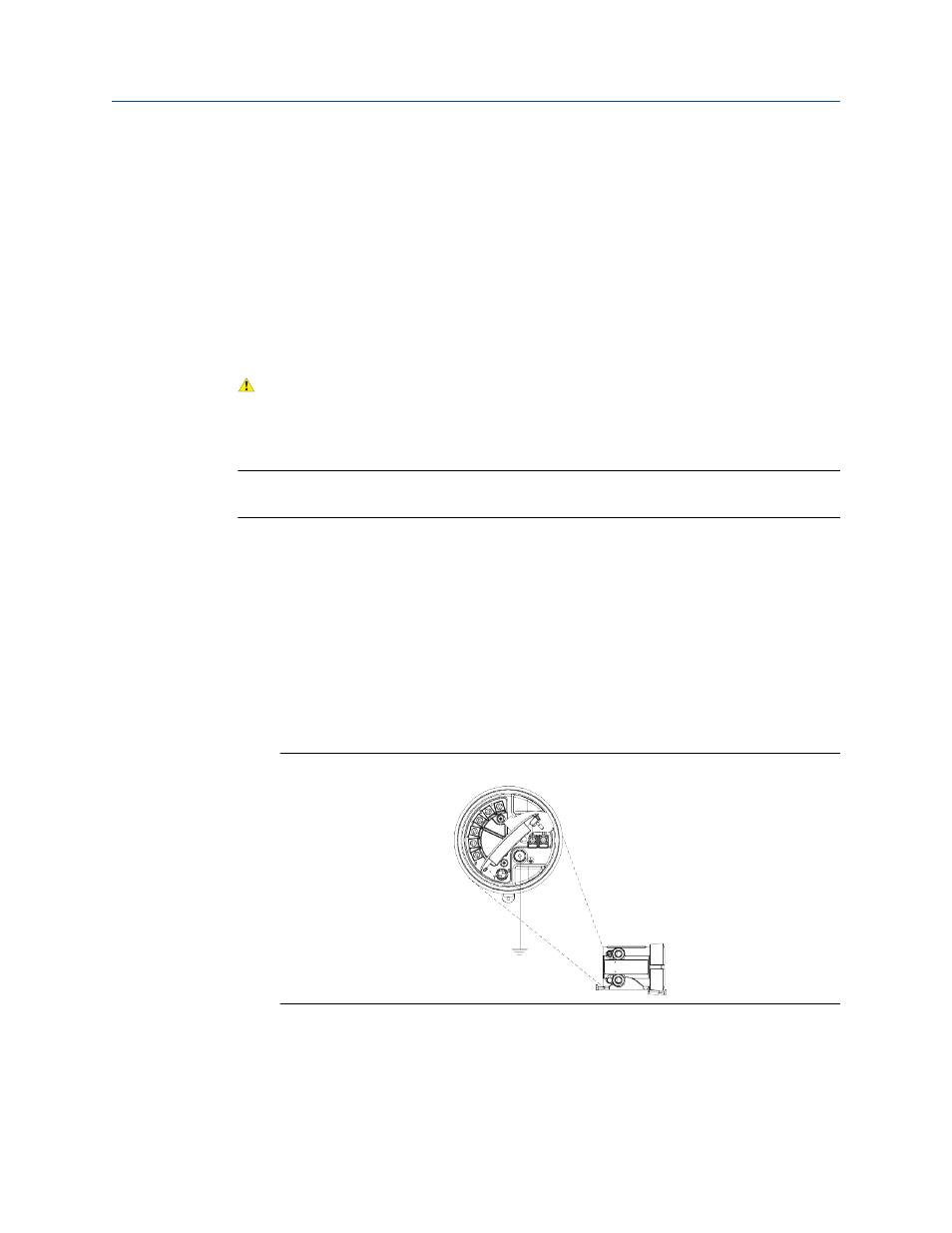

Ground the transmitter/core processor assembly according to applicable local

standards, using the transmitter’s internal ground screw or the transmitter's

external ground screw.

Transmitter internal ground screw

Figure 4-17:

Mounting and sensor wiring for 9-wire remote installations

Installation Manual

47