Vertical termination (continued) – Empire Comfort Systems DVD32FP3 User Manual

Page 35

23552-4-0408

Page 35

Installation of Vertical Inlet Baffle

The vertical inlet baffle is to be used only in a completely vertical

vent installation. The vertical inlet baffle can be used when the

vertical vent rise is between 10 feet and 40 feet. To maintain the

yellow flame in the main burner, purchase Vertical Inlet baffle,

DVF-139 from your Empire Comfort Systems, Inc. distributor or

dealer for Simpson Duravent only.

In a vertical vent rise the rear (yellow) flame on the main burner can

be reduced due to the drawing action from the flue exhaust pipe and

the air inlet pipe. A decrease in the height or the appearance of the

yellow flame may occur when the vertical vent rise is between 10

feet and 40 feet. To enhance the yellow flame on the main burner,

the vertical inlet baffle can be attached to the direct vent high wind

vertical top.

Please use the following steps to install the vertical inlet

baffle.

1. Place the vertical inlet baffle over the exterior of the air inlet

openings on the direct vent high wind vertical top.

2. There are three sections of air openings on the exterior of the

air inlet pipe.

To achieve the maximum amount of yellow flame the vertical

inlet baffle will cover-up three sections of air openings.

To achieve the minimum amount of yellow flame the vertical

inlet baffle will cover-up one section of air openings.

3. Attach vertical inlet baffle to the direct vent high wind vertical

top with (2) 3/8" hex-head screws provided with vertical inlet

baffle.

4. Installation of vertical inlet baffle is completed.

Parts List

Description

Part

Number

Quantity

Supplied

Vertical Inlet Baffle

DVF-139

1

3/8" Hex-Head Screw

R-2656

2

Reassembly and Resealing Vent Pipe System

Attach vent pipe to inlet and outlet vent adaptor on fireplace in either

the vertical or horizontal position, replace horizontal and vertical

pipe lengths, elbows and horizontal or vertical termination kit.

All vent system components lock into place by sliding the concentric

pipe section with four (4) equally spaced interior beads onto the

appliance collar or previously installed component end with four

(4) equally spaced indented sections. When the internal beads of

each starting outer pipe line up, rotate pipe section clockwise 90°

(approximately 3 inches). The vent pipe is now locked together.

Continue replacing components per the vent system configuration.

Be certain that each succeeding vent component is securely fitted

and locked into the preceding component in the vent system.

Reassembly and Resealing Gas Accumulation Relief System

Glass Frame Assembly and Combustion Chamber

Whenever the glass frame assembly is pivoted open by a delayed

ignition in the main burner, the glass frame assembly gaskets and

combustion chamber must be examined by a qualified service person

for damage. All damaged gaskets on the glass frame assembly and

combustion chamber must be replaced by a qualified service person.

If damage occurs to the combustion chamber, it must be replaced

by a qualified service person. Contact Empire Comfort Systems,

Inc. for replacement parts.

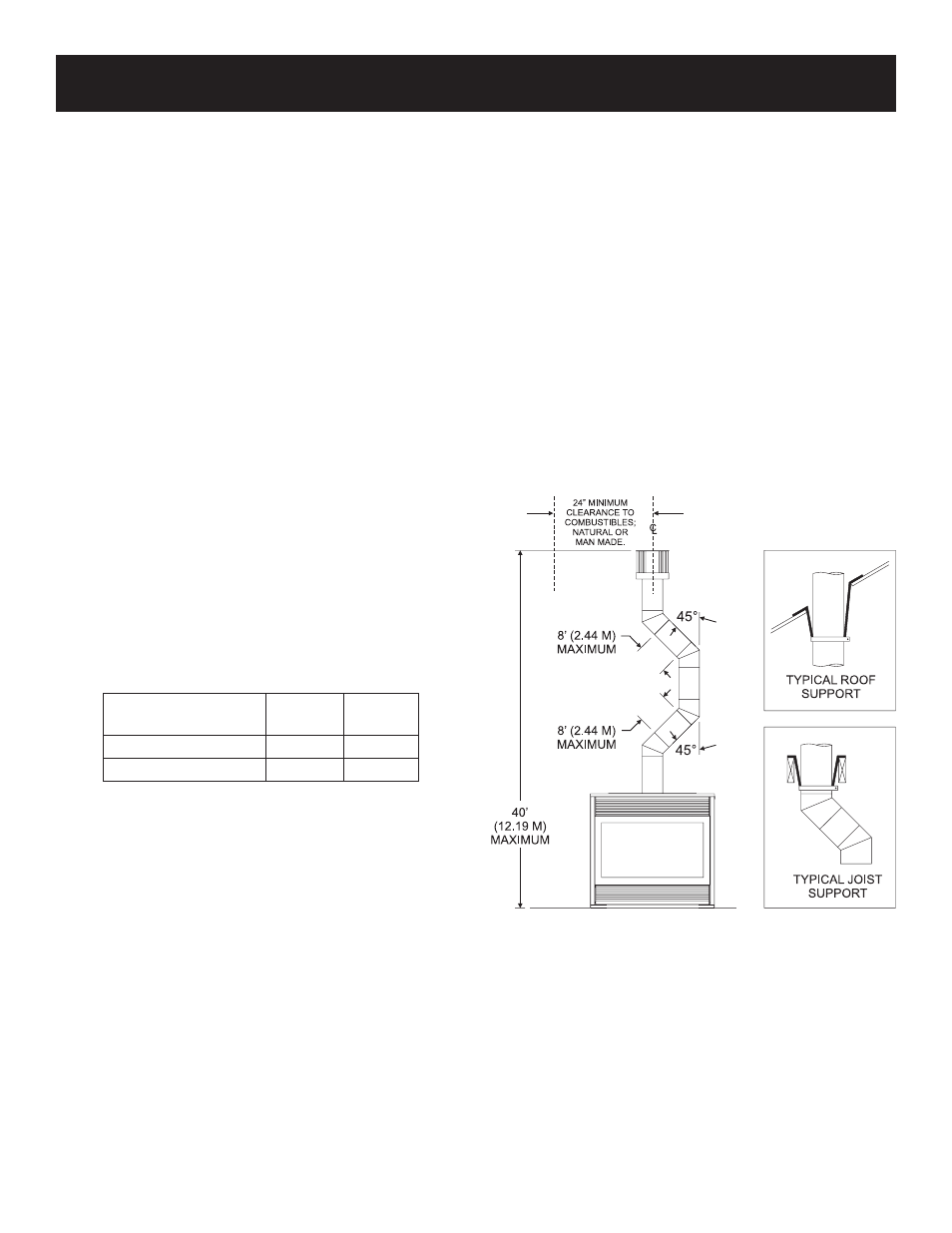

Vertical Through the Roof Applications (Figure 53)

Your Gas Fireplace has been approved for:

a) Vertical installations up to 40 feet in height.

b) Two sets of 45 degree elbow offsets within these vertical

installations. From 0 to a maximum of 8 ft. a vent pipe can be

used between elbows.

c) Wall straps must be used to support offset pipe every 4'.

This application will require that you first determine the roof pitch

and use the appropriate venting components.

Figure 53

VERTICAL TERMINATION (continued)