EMI CAC User Manual

Page 10

www.enviromaster.com

CAC Cassette Evaporator

10

PIPING DO’S AND DON’TS

• Avoid piping on a rainy day.

• Use refrigerant grade copper tubing.

• Use a tubing bender and avoid unnec-

essary bending.

• Cap ends of lines until ready for fi nal

connections.

Once the unit is mounted and level the Cassette piping connections can be made.

Any change in the diameter of the tubing

MUST be made at the indoor connec-

tion. Line-set diameter is determined by

the condenser valve size

.

Use of a larger line can harm

the compressor!

When matching a the CAC24 with an

18,000 Btuh condenser, the interconnecting

suction line needs to be 5/8” O.D. to match

the condenser service valve connection.

Therefore the 3/4” O.D. suction connection

of the CAC24 unit needs to be reduced to

5/8” at the CAC24 unit connection to match

the 5/8” line of the condenser.

5/8” bushing goes on suction line

(

Only when matched to an 18,000 Btuh condenser)

NOTE: Refrigerant and condensate

pipes should be insulated right up to the

Cassette chassis.

The CAC is equipped with a Flo-Rater/

Piston Expansion device. Connections are

sweat type.

The suction line (large) must be insulated

the entire length with closed cell, foam tube

insulation. Do not insulate the liquid line

(small). Connect the outdoor unit according

to the instructions supplied with unit.

All horizontal piping runs must be level

and without dips to trap the oil.

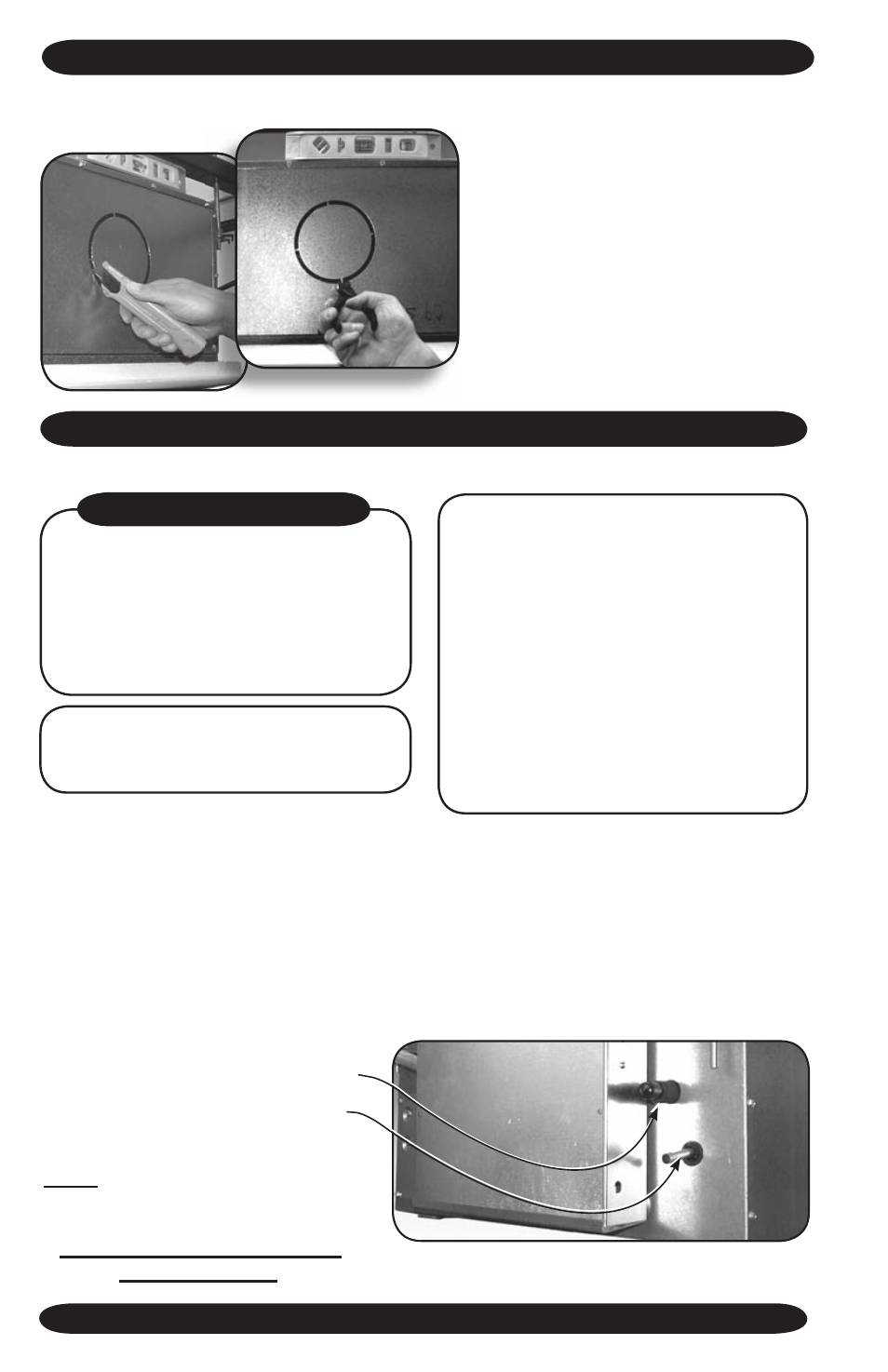

Suction Line

Liquid Line

REFRIGERATION PIPING

PIPE INSTALLATION NOTES

1. Maximum equivalent pipe run should

be no more than 100’, with a maximum

rise of 35’.

2. Horizontal pipe runs should be slight-

ly inclined, so as to encourage oil to

fl ow in the direction of the compres-

sor, for better oil return.

3. Good refrigeration practices must

be employed to ensure the correct

pressure drop and good oil return.

2. Cut the black insulation around the

knock-out.

3. Snip the tabs holding the knock-

out in place.

4. Remove the metal knock-out and

the black insulation behind it.

5. Attach the duct collars (fi eld sup-

plied) to the chassis using self tap-

ping screws.

(Repeat steps 1-5

for remaining duct work.)

CONDENSATE PIPING