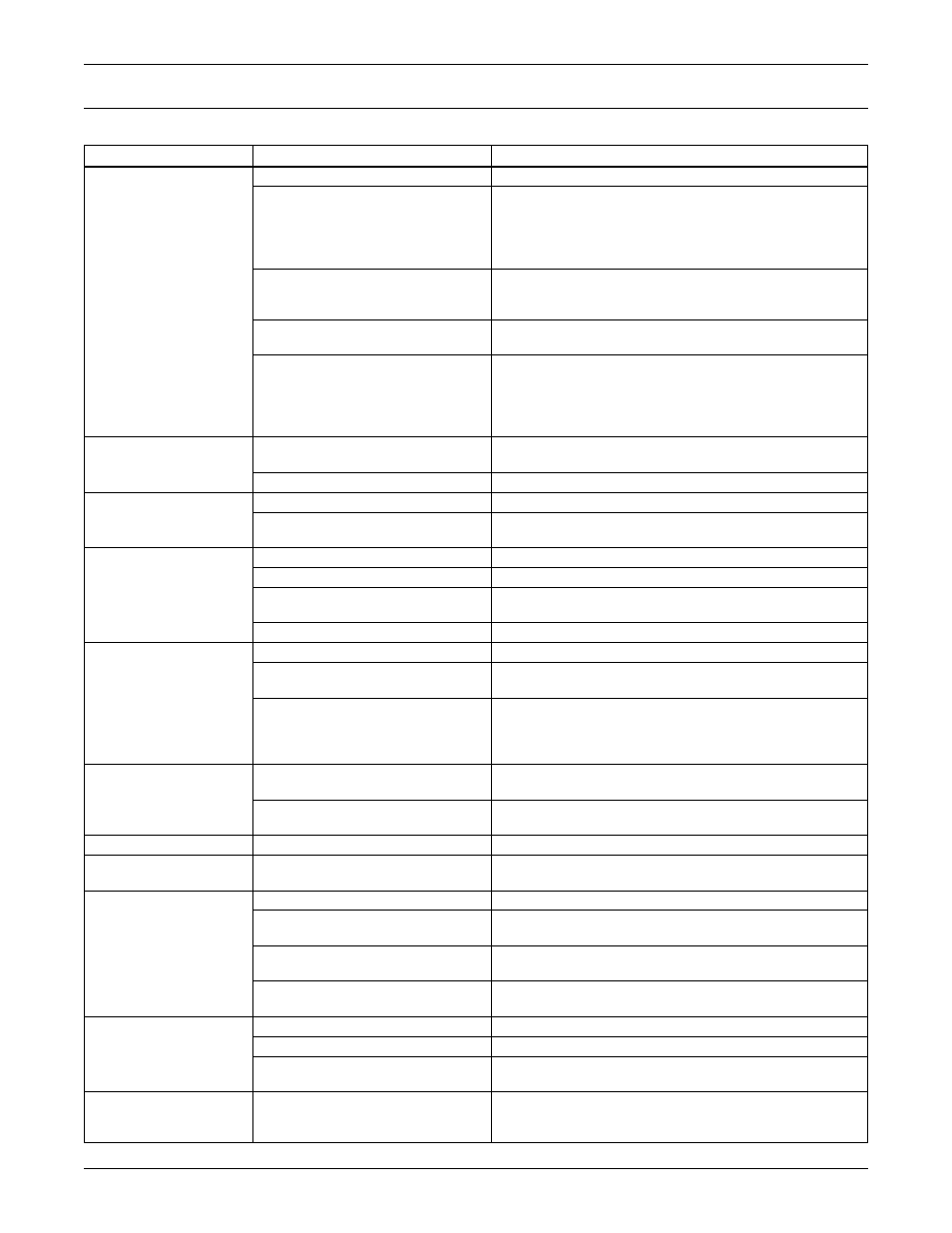

0 troubleshooting, Table 23 troubleshooting, Roubleshooting – Emerson Precision Cooling For Business-Critical Continuity Figure i User Manual

Page 35: Table 23, Troubleshooting

Troubleshooting

31

5.0

T

ROUBLESHOOTING

Table 23

Troubleshooting

Problem

Cause

Remedy

Unit will not start

No power to unit

Check voltage at input terminal block.

Compressor contactor not pulling in

Check for 24VAC ±2VAC at control connections 1 & 2. If

no voltage, check control setting requires cooling. If there

is voltage, lockout relay may be energized. Check for

24VAC at control connections 2 & 3. If there is voltage,

see compressor high-discharge pressure/lockout relay.

Control voltage circuit breaker (at

transformer in evaporator module)

open

Locate short and reset circuit breaker.

Short cycle prevention control

Control software delays compressor 3 minutes from stop

to start.

Compressor high discharge

pressure/ lockout relay

Check for 24VAC ±2VAC at control connections 2 & 3.

Remove 24VAC signal at Connection 2 by turning indoor

unit control off, then back on, or by raising the setpoint to

remove the cab for cooling, then resetting to re-establish

operation.

High discharge

pressure

Insufficient air flow across

condenser coil

Check fan operation. Remove debris from coil and air

inlets.

High refrigerant charge

Check refrigerant charge.

Low discharge pressure

Faulty head pressure control valve

Replace if defective.

Compressor rotation in reverse

direction

Check for proper power phase wiring to unit and to

compressor motor.

Low suction pressure /

compressor cycling

Insufficient refrigerant in system

Check for leaks; repair and add refrigerant.

Plugged filter drier

Replace filter drier.

Improper superheat adjustment

Reset expansion valve for 10-15°F (5.6 to 8.4°C)

superheat at evaporator.

Defective liquid line solenoid valve

Check valve and coil; replace if necessary.

Low compressor

capacity/ no cooling

Defective liquid line solenoid valve

Check valve and coil; replace if necessary.

Plugged filter drier

Check pressure drop across filter drier. Replace filter

drier.

Low refrigerant charge

Check for normal system operating pressures. Refer to

abnormal pressure causes if applicable. Check for leaks.

Proper refrigerant charge is very important at low ambient

operation.

Compressor noisy

Loose compressor or piping

support

Tighten clamps.

Compressor rotation in reverse

direction

Check for proper power phase wiring to unit and to

compressor motor.

Pipe Rattle

Loose pipe connections

Check pipe connections.

Compressor running hot

Compression ratio too high

Check for normal system operating pressures. Refer to

abnormal pressure causes if applicable.

Compressor motor

protectors tripping or

cycling

High discharge pressure

Check for blocked condenser fan or coil.

High suction temperature

Check expansion valve and hot gas bypass valve setting.

Check liquid quenching valve operation.

Loose power or control circuit

wiring connection

Check all power and control circuit connections.

Defective motor

Check for motor ground or short. Replace compressor if

either condition is found.

Compressor cycles on

locked rotor

Low line voltage

Check line voltage and determine location of voltage drop.

Compressor motor defective

Check for motor winding short or ground.

Single phasing

Check voltage across all 3 legs at contactor. Correct

source of problem.

Motor burnout

Check control panel for welded

contactor contacts or welded

overload contacts.

Replace defective components.