6 electrical connections, Table 13 design refrigerant pressures, Table 14 application limits – Emerson Precision Cooling For Business-Critical Continuity Figure i User Manual

Page 25: 1 low-voltage control wire connections, 2 low-voltage control wire sizing, Table 15 recommended minimum wire size, Electrical connections, Low-voltage control wire connections, Low-voltage control wire sizing, Table 13

Installation

21

2.6

Electrical Connections

Each unit is shipped from the factory with all internal wiring completed. All power, control wiring

and ground connections must be made in accordance with the National Electrical Code and local

codes. Refer to equipment nameplate regarding wire size and circuit protection requirements. Refer to

Figures 5, 7 and 8 and electrical schematic (reference Figures 9 through 11) when making connec-

tions. A manual electrical disconnect switch should be installed within 5 feet (1.6 m) of the unit in

accordance with codes.

The three-phase scroll compressor requires proper phasing to ensure correct motor rotation. The com-

ponent connections have been phase synchronized at the factory. Power phasing should be changed

only at the line voltage supply to the unit. To change phasing, switch any two power leads to the unit.

Observe system pressures to determine whether the unit is operating properly.

2.6.1 Low-Voltage Control Wire Connections

Field-supplied four-wire control connection (10-wire on 8-ton units) is required between the outdoor

condensing unit and the evaporator. Refer to Figures 5, 7 and 8 and to unit electrical schematic and

2.6.2 Low-Voltage Control Wire Sizing

Low-voltage wiring should be sized to allow a 1 volt maximum drop due to line resistance between the

evaporator and condensing unit. Use NEC Class 1 or 2 wiring according to wire routing conditions

chosen, local codes and application limits in Tables 14 and 15.

!

WARNING

Use voltmeter to be sure power is turned off before making any electrical connections.

!

CAUTION

Three-phase power must be connected to the unit line voltage terminals in proper sequence so

that scroll compressor rotates in the correct direction.

!

CAUTION

Apply power to condenser 8 hours before operating system. This time is required to allow

liquid refrigerant to be driven out of the compressor. This is especially important at low

ambient temperatures. The compressor crankcase heater is energized as long as power is

supplied to the unit.

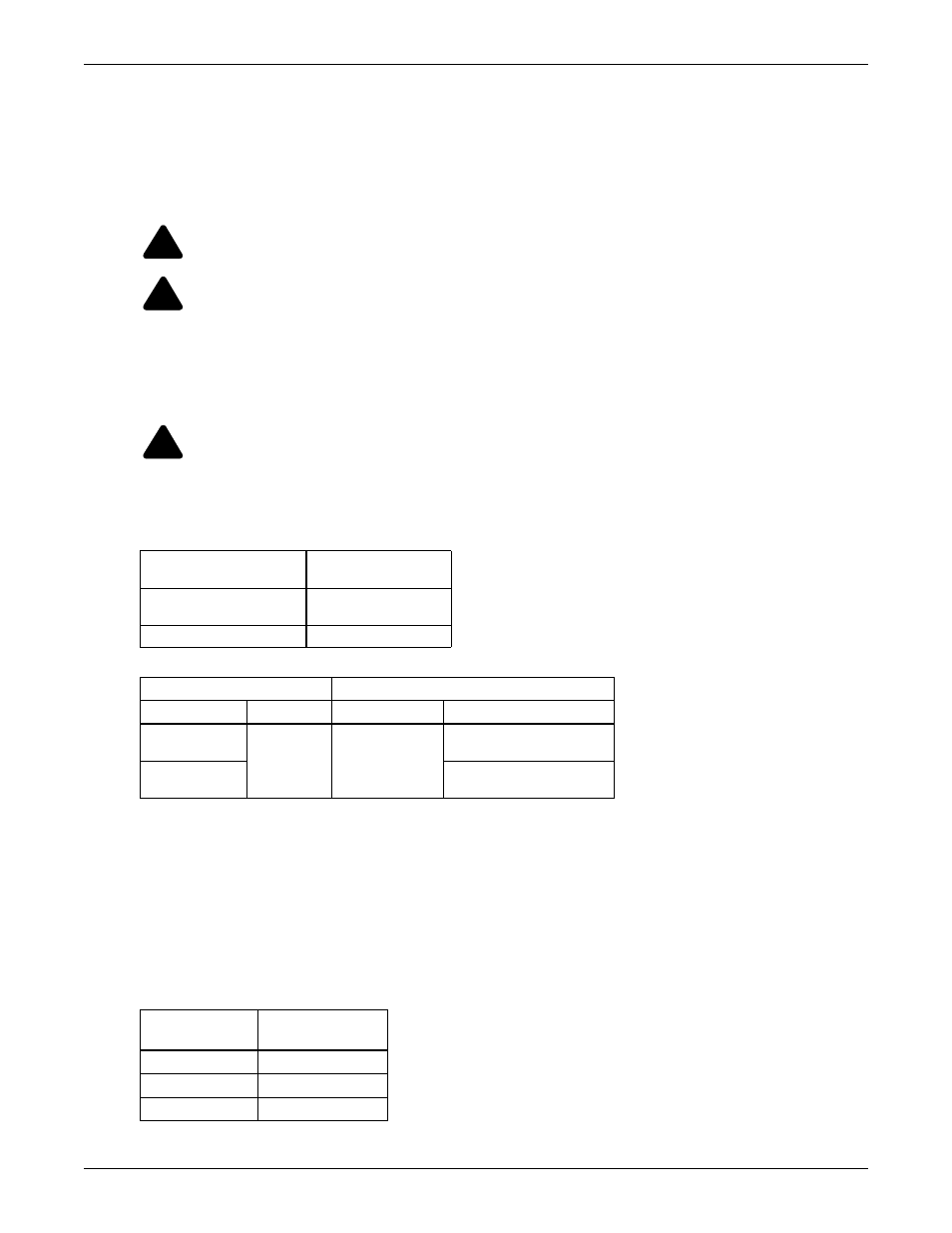

Table 13

Design refrigerant pressures

Suction

53 - 95 PSIG

(365 to 655 kPa)

Discharge

(At Design Ambient)

280 psig (1930 kPa)

High Pressure Cutout

400 psig (2760 kPa)

Table 14

Application limits

Input voltage

Dry Bulb Air Temperature at Condenser

Minimum

Maximum

Minimum

Maximum

-10%

+10%

-30°F (-34°C)

115°F (46°C) Std

Ambient & Quiet-Line

-5% 208/230V

single-phase

125°F (52°C)

High Ambient Models

Table 15

Recommended minimum wire size

Max. Distance*

ft. (m)

Min. Wire Gauge

AWG (mm2)

50 (15)

20 (0.75)

100 (30)

18 (1.0)

150 (45)

16 (1.5)

* One-way control wire run between outdoor condensing unit and evaporator.