4 field charge verification, Table 22 field verification charge, Field charge verification – Emerson Precision Cooling For Business-Critical Continuity Figure i User Manual

Page 34: Table 22, Field verification charge

Maintenance

30

4.4

Field Charge Verification

An integral sightglass is provided with the receiver to assist in field charge verification. During

charge verification set the control temperature down to keep the system running. If the system is

equipped with hot gas bypass, de-energize it by removing power from the hot gas solenoid valve coil.

To remove power, disconnect the solenoid leads from the unit contactor in the electric box (refer to

specific unit schematic; reference Figures 7 through 10). When charge verification has been com-

pleted, replace and secure all wire connections and covers.

During operation at design ambients (95 or 105°F; 35 or 41°C) the charge level will be above the sight-

glass in the receiver. If levels are below the sightglass an undercharge condition is likely. If levels are

above the sightglass and higher discharge pressures than normal are observed an overcharge condi-

tion may be likely. However, verify that other high discharge pressure causes such as dirty coil and

restricted airflow are not responsible before removing charge.

At temperatures below design ambient, refrigerant backs into the condenser coil and the level in the

receiver will drop below the sightglass. If you are trying to verify charge level at lower ambients, block

the condenser coil to maintain 230 psig (1585 kPa) discharge pressure to ensure the head pressure con-

trol valve is closed. At these conditions the charge level should be above the sightglass in the receiver.

NOTE

The 5-ton high ambient, 5-ton Quiet-Line and 8-ton models consist of two condenser coils and

two receivers. When restricting airflow on these units, the coils should be blocked off

proportionally. If one coil is restricted significantly more than the other, liquid can remain in

the restricted coil causing lower levels in the receivers. The receiver liquid level should be above

the sightglasses in both receivers. There may be some variation in charge level between the two

receiver sightglasses due to piping and assembly variations. When adding charge, determine

which receiver level is lower and use that sightglass to gauge charge level.

NOTE

If no level is visible in the sightglass, add charge until the level is in the middle of the

sightglass. Check the discharge pressure during this procedure and adjust coil restrictions to

maintain 230 psig (1585 kPa). Once the charge is in the middle of the sightglass, add

additional system charge per Table 22. After charging, unblock the coil and allow the unit to

operate normally. After conditions have stabilized, restrict the coil if required to maintain 230

psig (1585 kPa) discharge pressure and verify that the charge level is above the sightglass.

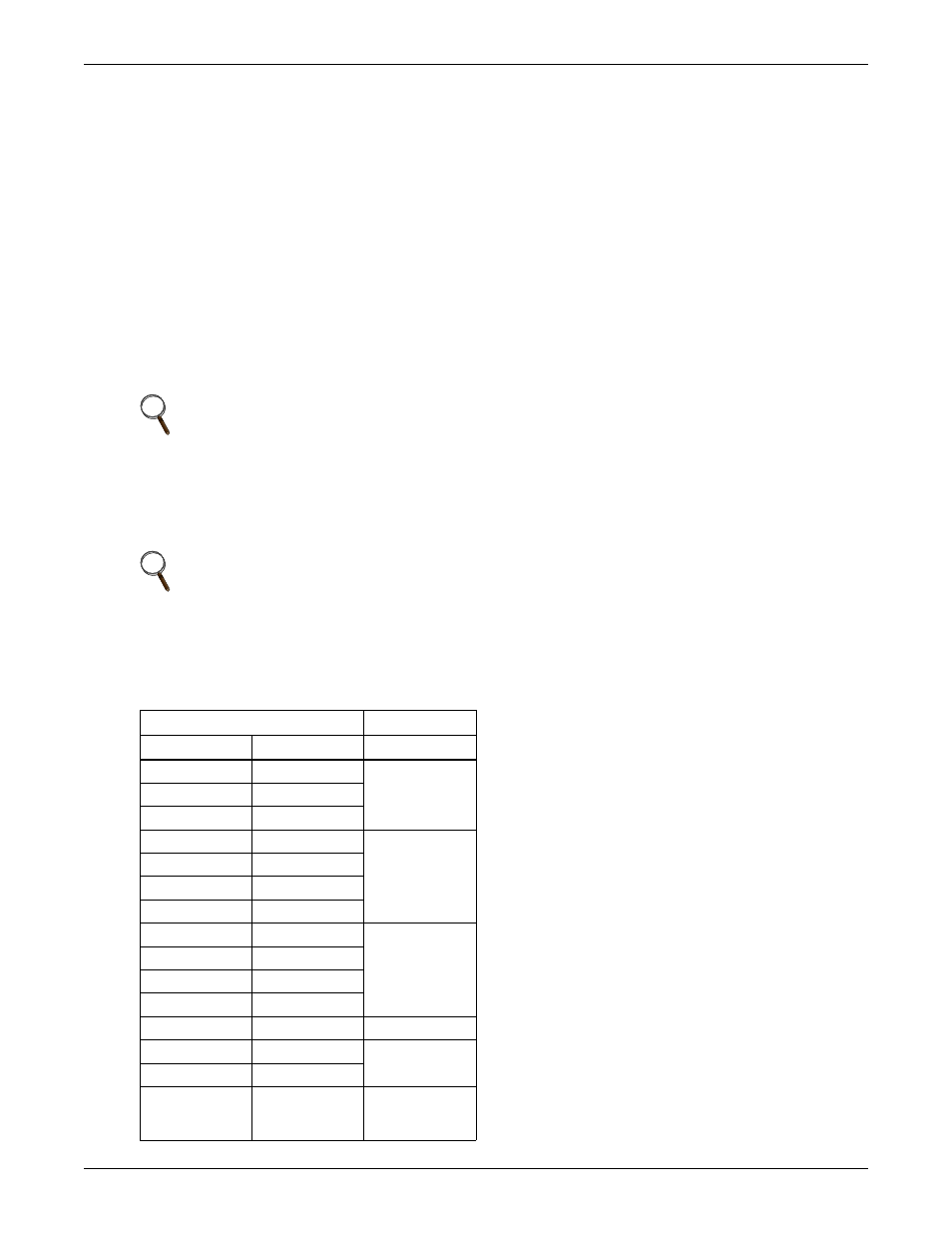

Table 22

Field verification charge

Model Numbers

R-407C

60 Hz

50 Hz

oz (kg)

PFH014A-_L

PFH013A-_L

4 (0.11)

PFH020A-_L

PFH019A-_L

PFH027A-_L

PFH026A-_L

PFH027A-_H

PFH026A-_H

18 (0.51)

PFHZ27A-_L

PFHZ26A-_L

PFH037A-_L

PFH036A-_L

PFH042A-_L

PFH041A-_L

PFH037A-_H

PFH036A-_H

8 (0.23)

PFHZ37A-_L

PFHZ36A-_L

PFH042A-_H

PFH041A-_H

PFHZ42A-_L

PFHZ41A-_L

PFH067A-_L

PFH066A-_L

18 (0.51)

PFH067A-_H

PFH066A-_H

50 (1.42)

PFHZ67A-_L

PFHZ66A-_L

PFH096A-_L

3-ton circuit

5-ton circuit

PFH095A-_L

3-ton circuit

5-ton circuit

18 (0.51)

18 (0.51)