Installation 13 – Emerson Precision Cooling For Business-Critical Continuity Figure i User Manual

Page 17

Installation

13

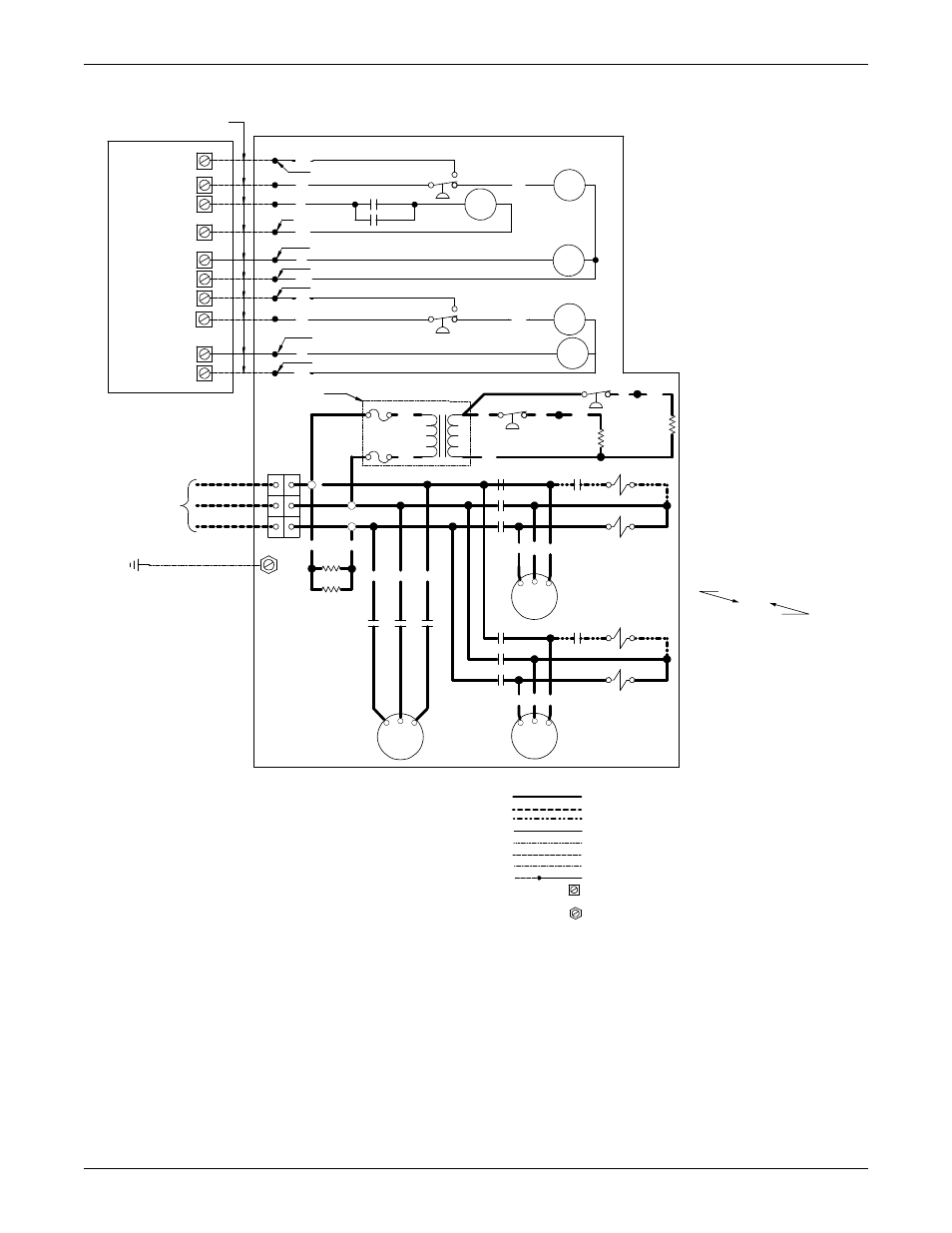

Figure 11 Three-phase, 8 ton model schematic, typical

3

2

10

9

4

1

7

6

8

5

6

L1

L2

L3

See Note 6

See Note 8

See Note 7

See Note 7

See Note 8

See Note 8

See Note 1

See Note 6

C1 Aux.

C2 Aux.

HP1

MF

C1

C2

BK

HP2

W

BL

BR

R

BR

R

W

BL

R

BR

5

8

7

1

4

9

10

2

3

BK

BR

BR

R

BK

HP3

R

BK

BK

RHTR1

RHTR2

HP4

1C1

2C1

3C1

HG1

HGSV1

LLSV1

BR BR BR

1MF 2MF 3MF

BR R OR

T3 T2 T1

COMP1

T3 T2 T1

COMP

2

BR R OR

1C2

2C2

3C2

HG2

HGSV2

LLSV2

R

F1

F2

TX1

BK

BK

NOTES

1. Transformer TX1 provided on units with nameplate voltages greater than 250V.

2. Use copper conductors only. See unit nameplate for main supply wire sizing data.

Wire per local codes.

3. A remote disconnect switch is to be field-supplied and mounted within sight of the

condensing unit. See unit nameplate for voltage and amperage.

4. All motors have internal line break overload protectors.Three-phase motors

protected for primary single-phasing conditions.

5. Terminals 1 thru 8 are for connection of control circuit from evaporator unit.

(Terminals 4 and 8 are not used by some evaporator models . See Note 7). Wiring by

others to be NEC Class 2 and sized for 1V maximum drop.

6. Connection to Terminals 3 and 7 is used for high head alarm input connection in

evaporator unit.

7. Connection to Terminals 4 and 8 is required only on models with (HGBP) hot gas

bypass control signal output in evaporator unit.

8. Wires 1, 5 and 9 are separately connected to the grounded side of the 24V

Class 2 circuit. Do not connect them together.

STANDARD DEVICES

C1 - Compressor Contactor 1

C2 - Compressor Contactor 2

CHTR1 - Compressor Heater 1

CHTR2 - Compressor Heater 2

COMP1 - Compressor #1

COMP2 - Compressor #2

F1 - Transformer Fuse

F2 - Transformer Fuse

FM - Fan Motor

HP1 - High Pressure Switch 1

(Auto Reset)

HP2 - High Pressure Switch 2

(Auto Reset)

HP3 - Pressure Switch 3

Receiver (Auto Reset)

HP4 - Pressure Switch 4

Receiver (Auto Reset)

LLSV1 - Liquid Line Solenoid Valve 1

LLSV2 - Liquid Line Solenoid Valve 2

MF - Fan Motor Contactor

RHTR1 - Receiver Heater No.1

RHTR2 - Receiver Heater No.2

TX1 - Transformer Line Voltage to 230V

OPTIONAL DEVICES

HG1 - Hot Gas Relay 1

HG2 - Hot Gas Relay 2

HGSV1 - Hot Gas Solenoid 1

HGSV2 - Hot Gas Solenoid 2

WIRING LEGEND

Factory-supplied line voltage

Field-installed line voltage wiring

Optional line voltage wiring

Factory-supplied 24V NEC Class 2 wiring

Optional 24V wiring

Field-supplied 24V NEC Class 2 wiring

Field-supplied earth grounding wire

Pigtail leads

Terminal strip connection

Grounding lug connection

WIRE COLOR CODE

OR - Orange

R - Red

BR - Brown

P - Purple

GN - Green

Y - Yellow

BL - Blue

BK - Black

W - White

Insulation Color

GN / Y

Tracer Color

COMP2

Conductors Field-Supplied

(See Note 5)

Evaporator Unit

HIGH HEAD 1

24V GND

COMP1

HGBP1

HIGH HEAD 2

COOLING 2

COOLING 1

HGBP2

OUTDOOR CONDENSING MODULE

3-Phase Line

Voltage Supply

By Others

(See Notes 2 and 3)

Earth Ground

By Others

CHTR1

CHTR2

FM

Fan

Motor

HG2

HG1