Chapter 6, Troubleshooting, Troubleshooting via led displays – Delta PROFIBUS-DP Module for VFD Series Drives PD-01 User Manual

Page 32: Chapter 6 troubleshooting

PD-01 PROFIBUS-DP Module

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

29

Chapter 6 Troubleshooting

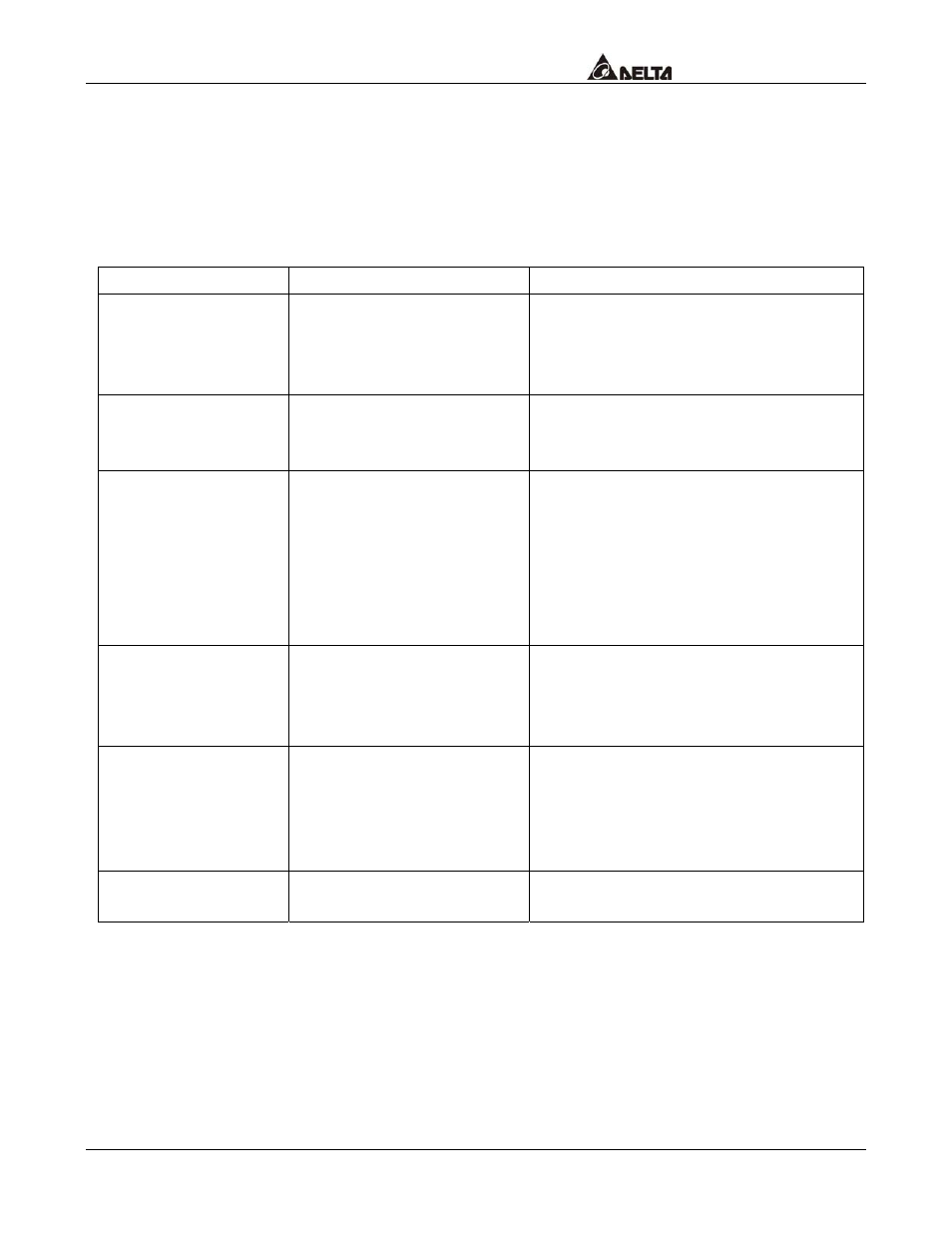

Troubleshooting via LED displays

Two LEDs, SP and NET LED, are used to monitor the PD-01 communication status.

Possible LED displays of NET LED:

LED Indication Corrective

Actions

OFF

No Power Supply

Verify that the power supply of PD-01.

Check whether the power supply is

connected and that power is applied to

the PD-01 through the connector.

Red, flickering (rapid

blinking)

Invalid PROFIBUS

address

set via switch

Check whether the switch value is

valid, valid value of slave is within

1-125. Set the valid value and re-power

Red, blinking

Communication link to

PROFIBUS, but No cyclical

data exchanged, or

Extended user parameter

error

User parameter are sent by master

(from GSD file), for example, if d_state

is set 1, ensure the data in Data Output

1 ~ Data Output 1 + dout_len are

continuous addresses. Otherwise,

PD-01 will not be able to pass the

Parameterization check.

Red ON

No connection to

PROFIBUS

1. Verify that network installation is OK.

2. Verify that PLC is working.

3. Verify that switch address setting is

correct.

Green, blinking

“Master” is in “Stop” mode,

and cyclical process data

exchange in progress, but

set-points invalid (control

word = 0)

Turn the KEY of PLC to RUN mode,

and send the control command to

PD-01.

Green ON

Cyclic data exchange in

progress and OK