Warning, Models 1rvt7 and 1rvt8 – Dayton 1RVT8 User Manual

Page 17

®

Dayton Installation, Operation, Maintenance and Parts Manual

Models 1RVT7 and 1RVT8

17

16

This infra-red heater must be vented in accordance with

national, state, provincial and local codes and the

guidelines throughout this manual. Refer to the latest

edition of the ANSI Z223.1 (NFPA 54) Standard.

It is required that the upper levels of the space to be

heated are properly ventilated to supply combustion

air to the heaters and to sufficiently dilute the products

of combustion. It is also important to keep the flue

discharge area clear of gas piping and electrical wiring

(see Figure 2.10).

Provisions must also be made to provide sufficient fresh

air intake area and exhaust air outlet area. Natural or

mechanical means shall be provided to supply and

exhaust at least 4.0 CFM per 1000 BTU/H of gas input.

Exhaust openings for the removal of flue products must

be above the level of the heater(s).

Where insufficient air movement exists, induced air

Ventilation

WARNING

!

Improper or insufficient

ventilation may result in

explosion, fire, health

problems, carbon

monoxide poisoning or

death. Vent enclosed spaces and buildings according to

national, state, provincial and local codes.

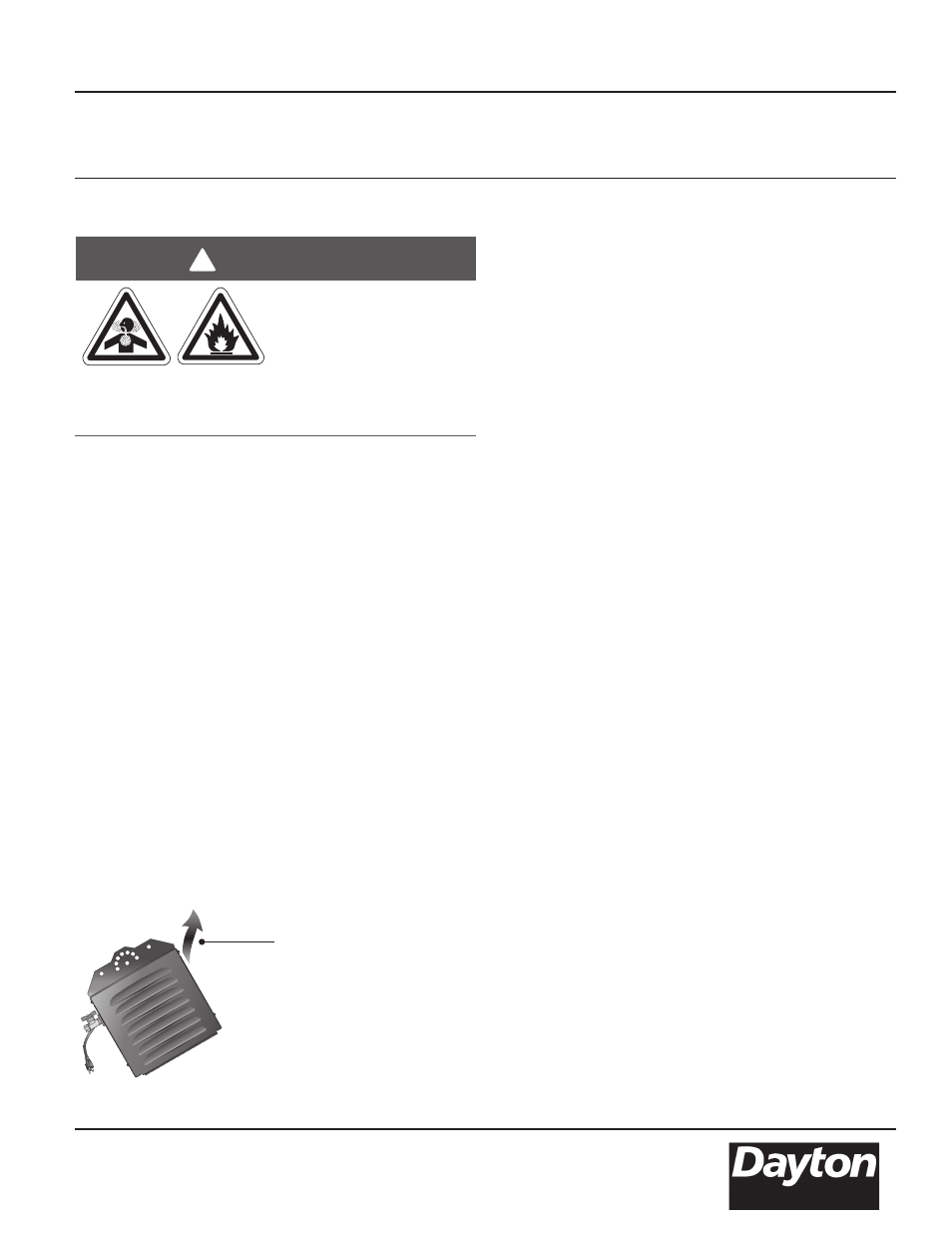

Figure 2.10 - Hot Flue Discharge

Discharge released from side

air channels. Keep area clear

of gas piping and electrical

wiring.

displacement is required. A balanced system is essential

to avoid negative building pressure which causes

excessive infiltration, unfavorable drafts and affects

combustion efficiency.

Air displacement may be accomplished by either gravity

or mechanical means. Mechanical exhausters are

preferred and typically mounted at high points on the

roof over where stagnant air accumulates inside. For

a flat roof, considerations of prevailing winds, high and

low pressure areas, and distribution of air movement

must be taken into consideration when locating

exhausters.

Best air distribution is accomplished by using a number

of small exhausters versus one large exhauster. Provide

a minimum of one square inch of inlet area per 1000

BTU/H for combustion air supply. Inlet opening in the

building should be well distributed, located high on the

wall and should direct incoming air upward to dilute

products of combustion while preventing drafts at lower

levels. Inlets are typically 1 to 3 sq. ft.

In certain applications, local codes may require that

mechanical exhaust systems be interlocked with the

heaters to enable both to function simultaneously or

allow control of exhausters with a ceiling mounted

humidistat.