Preventive maintenance, Replacement fuse chart, Unit heat exchanger maintenance – WaterFurnace Envision2 NXW Chiller User Manual

Page 38: Replacement procedures, In-warranty material return

38

ENVISION

2

NXW REVERSIBLE CHILLER INSTALLATION MANUAL

Unit Heat Exchanger Maintenance

1.

Keep all air out of the water or antifreeze solution.

2.

Keep the system under pressure at all times. Closed

loop systems must have positive static pressure or air

vents may draw air into the system.

NOTES: If the installation is in an area with a known high

mineral content in the water, it is best to establish with

the owner a periodic maintenance schedule for checking

the water-to-refrigerant heat exchanger on a regular

basis. Should periodic cleaning be necessary, use standard

cleaning procedures. Generally, the more water flowing

through the unit, the less chance there is for scaling. Low

GPM flow rates produce higher temperatures through the

heat exchanger. To avoid excessive pressure drop and the

possibility of metal erosion, do not exceed GPM flow rate as

shown on the specification sheets for each unit.

Preventive Maintenance

Replacement Procedures

When contacting the company for service or replacement

parts, refer to the model number and serial number of the

unit as stamped on the serial plate attached to the unit.

If replacement parts are required, mention the date of

installation of the unit and the date of failure, along with an

explanation of the malfunctions and a description of the

replacement parts required.

In-Warranty Material Return

Material may not be returned except by permission

of authorized warranty personnel. Contact your local

distributor for warranty return authorization and assistance.

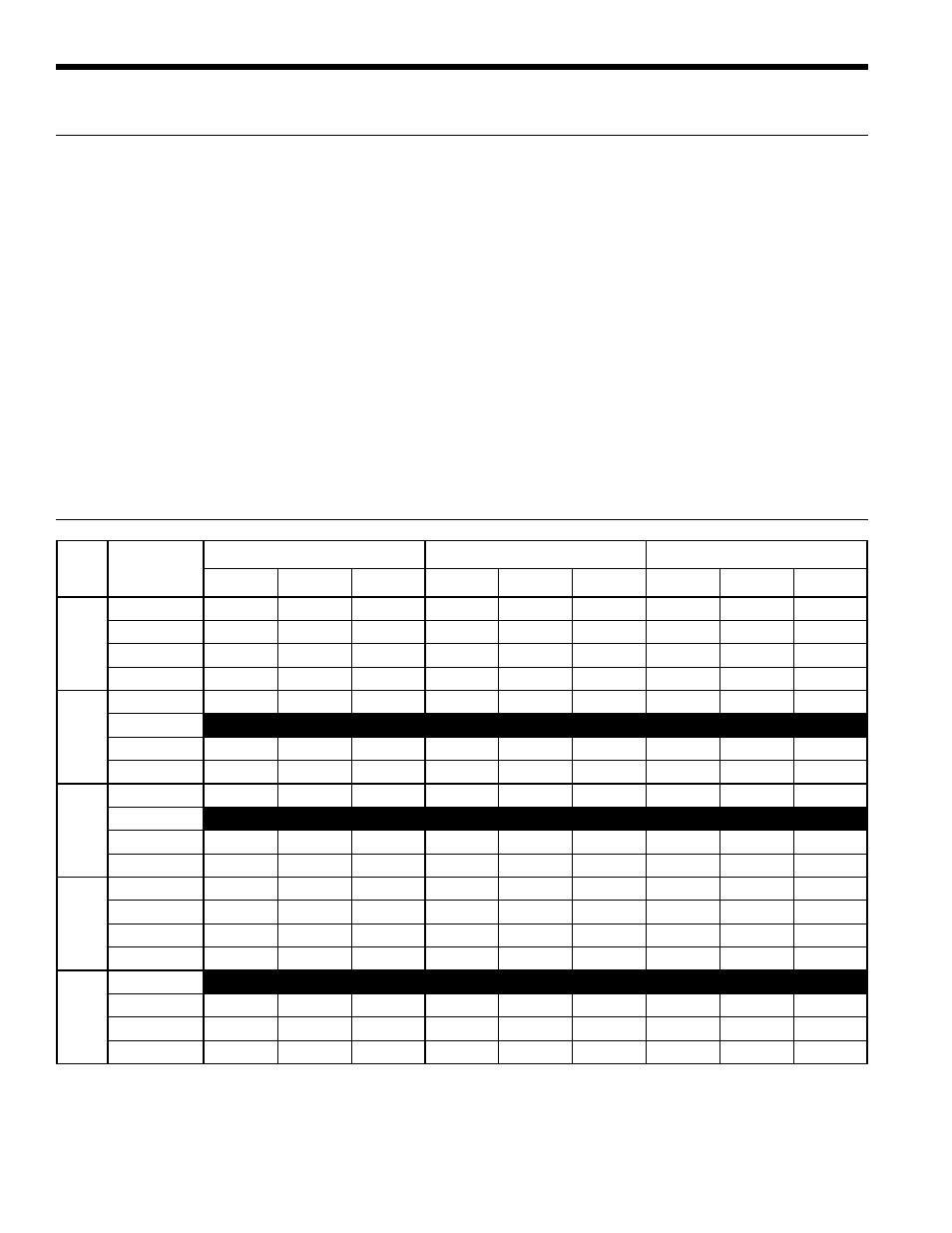

Replacement Fuse Chart

Model

Size

Line Voltage/

Frequency/ Phase

Disconnect Fuse (if applicable)

Branch Circuit Fuse

Transformer Primary Fuse

Size (A)

Type

Part #

Size (A)

Type

Part #

Size (A)

Type

Part #

120

208-230/60/3

60

Class J, Round

19P605-06

30

Cube*

19P602-04

1.3

Class CC

19P600-07

380/60/3

30

Class J, Round

19P605-03

20

Cube*

19P602-02

0.8

Class CC

19P600-03

460/60/3

30

Class J, Round

19P605-03

20

Cube*

19P602-02

0.6

Class CC

19P600-01

575/60/3

20

Class J, Round

19P605-01

15

Cube*

19P602-01

0.5

Class CC

19P600-13

180

208-230/60/3

70

Class J, Blade

19P605-07

40

Cube*

19P602-06

1.3

Class CC

19P600-07

380/60/3

460/60/3

30

Class J, Round

19P605-03

20

Cube*

19P602-02

0.6

Class CC

19P600-01

575/60/3

25

Class J, Round

19P605-02

15

Cube*

19P602-01

0.5

Class CC

19P600-13

240

208-230/60/3

80

Class J, Blade

19P605-08

45

Cube*

19P602-07

1.3

Class CC

19P600-07

380/60/3

460/60/3

45

Class J, Round

19P605-05

25

Cube*

19P602-03

0.6

Class CC

19P600-01

575/60/3

35

Class J, Round

19P605-04

20

Cube*

19P602-02

0.5

Class CC

19P600-13

360

208-230/60/3

110

Class J, Blade

19P605-10

60

Cube*

19P602-09

1.3

Class CC

19P600-07

380/60/3

80

Class J, Blade

19P605-08

45

Cube*

19P602-07

0.8

Class CC

19P600-03

460/60/3

60

Class J, Round

19P605-06

35

Cube*

19P602-05

0.6

Class CC

19P600-01

575/60/3

60

Class J, Round

19P605-06

30

Cube*

19P602-04

0.5

Class CC

19P600-13

600

208-230/60/3

380/60/3

110

Class J, Blade

19P605-10

60

Cube*

19P602-09

0.8

Class CC

19P600-03

460/60/3

100

Class J, Blade

19P605-09

50

Cube*

19P602-08

0.6

Class CC

19P600-01

575/60/3

70

Class J, Blade

19P605-07

40

Cube*

19P602-06

0.5

Class CC

19P600-13

* Meets Class J requirements