Field wiring and control setup, Line voltage, Low voltage operation – WaterFurnace Envision2 NXW Chiller User Manual

Page 19: Thermostat/controller (aquastat), Low voltage connections, Source flow switch (sfs), Load flow switch (lfs)

19

ENVISION

2

NXW REVERSIBLE CHILLER INSTALLATION MANUAL

TB

Typical AquaStat

24VAC

24V COM

Comp 1

Comp 2

Rev Valve

Acc 2

Acc 1

Alarm

Circuit 1 Alarm

Circuit 2 Alarm

24VAC

24V COM

Comp 1

Comp 2

Rev Valve

Accessory Item 1

R

C

Y1

Y2

O/B

X2

X1

L

LC1

LC2

R

C

Y1

Y2

B

NOTES:

1) Acc Output 1 is cycled with the lead compressor

2) Acc Output 2 is cycled with the lag compressor

Unit Power Supply

208-230/60/3,

460/60/3, or 575/60/3

G

L3

L1

L2

PB

Black

Red

White

Black

White

Red

Field Wiring and Control Setup

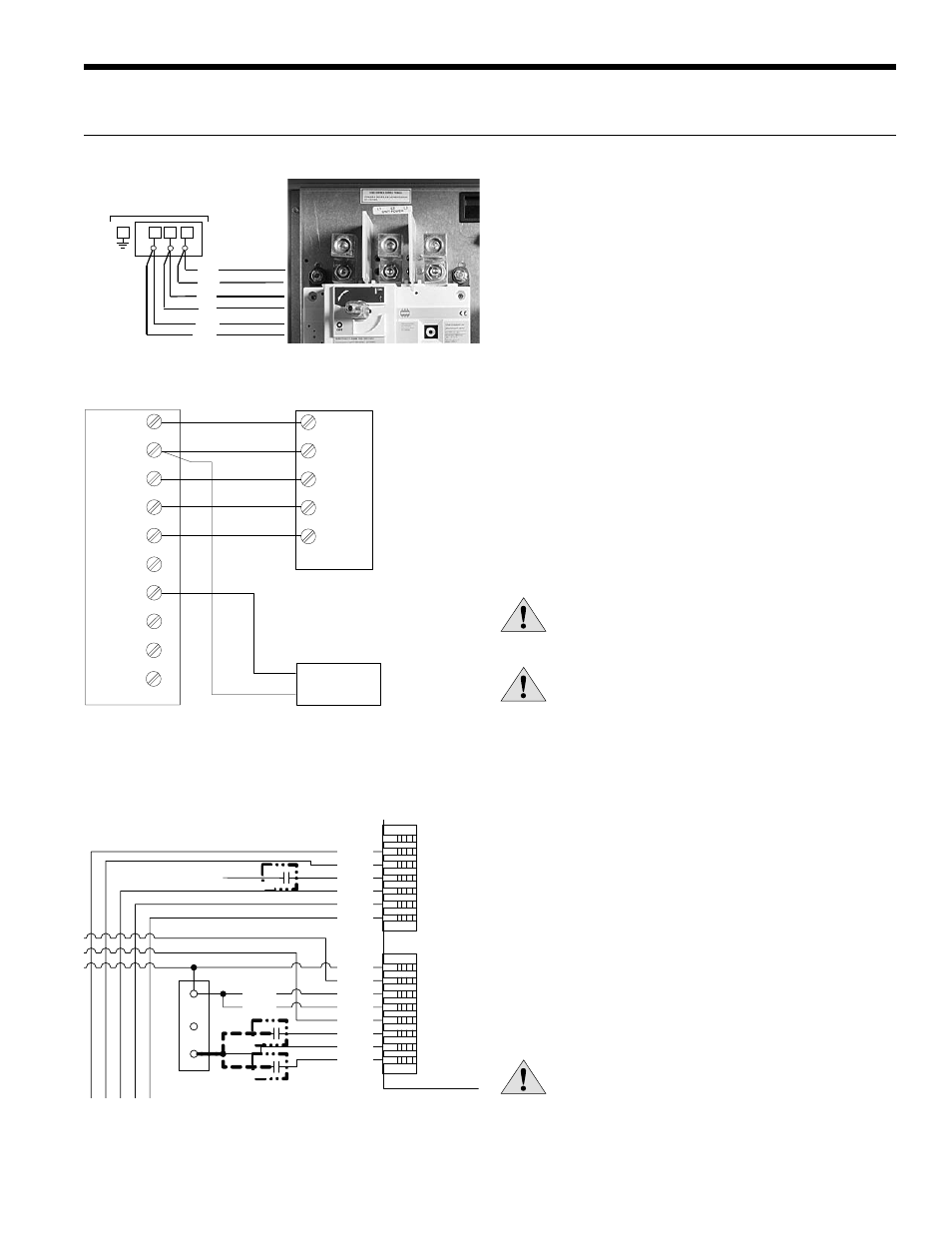

High Voltage Connections

Low Voltage Connections

Line Voltage

Power supply wiring connects directly to lugs on the topo

of the electrical disconnect. In 208-230V applications, heat

pumps are factory wired for 208V supply. In the case of

230V supply, the blue and red wires from the primary of the

transformer will need to be swapped.

Low Voltage Operation

Thermostat/Controller (Aquastat)

A two-stage 24VAC aquastat or liquid controller (field

supplied) must be used to turn the reversible chiller on/off, and

to switch modes for heating/cooling. Multiple chillers in the

same bank must be controlled from one aquastat/controller

(must be isolation relays for multiple unit applications).

Low Voltage Connections

Connect low voltage wiring as shown in Figure 9.

Connections shown are for typical aquastat. Actual

connections may vary with specific device used.

NOTE: If a separate transformer is used to supply a Y1, Y2, or

B signal to the unit controls, isolation relays must be used.

CAUTION: Use only copper conductors for field

installed wiring. Terminals in the unit are not

designed for other types of conductors.

WARNING: All wiring must comply with local and

state codes. Disconnect the power supply before

beginning to wire to prevent electrical shock or

equipment damage.

NOTE: Accessory 1 output is selectable as on with

compressor or off with compressor using the unit display.

on with compressor is the factory default setting.

Source Flow Switch (SFS)

Unit is factory shipped with no connections on Flow Switch

pins J10-45 (entering). If flow proving switch is required,

hook up as shown in Fig. 10 and Note 5. The unit will not

operate without flow proving inputs open.

Load Flow Switch (LFS)

Unit is factory shipped with no connections on Flow Switch

pins J9-56 (leaving). If flow proving switch is required, hook

up as shown in Fig. 10 and Note 4. The unit will not operate

without flow proving inputs open.

ATTENTION: Flow Switch inputs must be

made before unit will operate!

Wiring Schematic

SFS

LFS

ES

42

43

44

45

46

47

48

24VAC Com

DI12

DI11

DI10

DI9

DI8

DI7

49

50

51

52

53

54

55

56

DI 3/4/5/6/ Com

DI6

DI5

DI4

DI3

DI2

DI1

9VDC

J10

J9

2

3

1

PB2

Black (54)

Red (55)

Gray (56)

Pink (58)

Brown (57)

Gray (59)

Blue (45)

Blue (46)

Orange (47)

Gray (48)

Connect to R on TB

White (67)

White (66)

Blue (76A)

Blue (76B)

NOTE 1

NOTE 2

NOTE 4

NOTE 5

NOTE 8