Vortech Universal Small Block Chevy Carbureted User Manual

Page 20

P/N: 4GP020-015 v3.0, 2012-03-26

©2012 Vortech Engineering, Inc.

All Rights Reserved, Intl. Copr. Secured

10

A. Locate the supercharger drive assembly

(4GP116-041). Using the 7/16-20 x 2.75"

screw and washer, loosely install the appropri-

ate spacer for your application to the front of

the factory crank pulley.

B. Rotate the previously installed crank pulley

spacer to align the three mounting holes. Install

the supplied supercharger crank pulley and

secure using the supplied hardware. (3/8-24 x

5" for Serpentine and 3/8-24 x 4.75" for V-belt

applications.) Torque center bolt to 35 ft.lbs.

and the three pulley retainers to 25 ft.lbs.

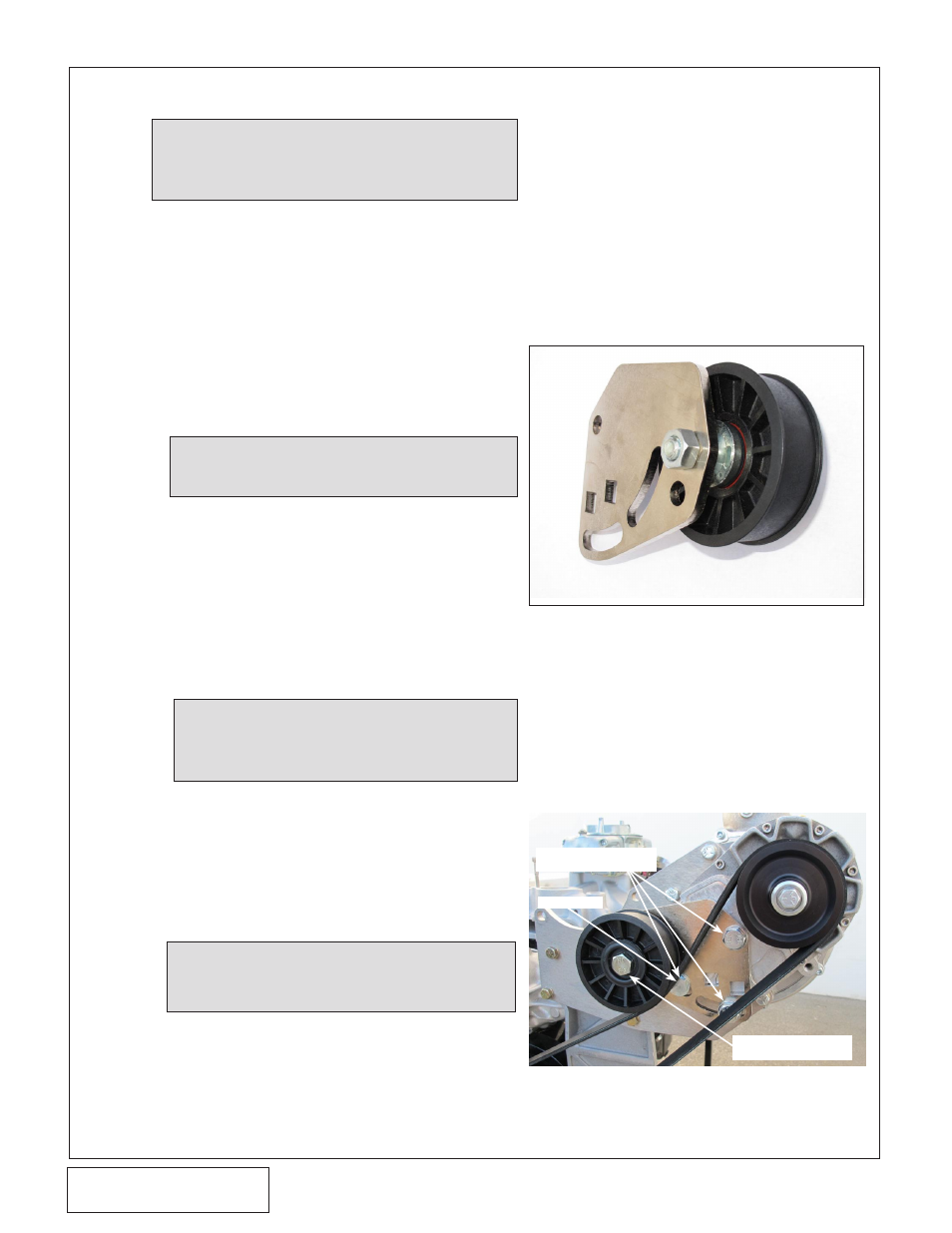

F.

Loosely install the belt tensioner

assembly onto the supercharger

using the M12 hardware provided.

Locate the supplied supercharger

drive belt and install between the

crank pulley and supercharger pul-

ley. Using a 1/2" ratchet, apply

tension to the supercharger drive

belt and secure the three M12

screws previously installed. (See

Fig. 5-a, 5-b, 5-c.)

5. CRANK PULLEY ANd SUPERCHARGER dRIVE PULLEY INSTALLATION

NOTE: If the supercharger drive pulley will not slide

onto the shaft DO NOT FORCE IT. Light

heating of the supercharger drive pulley with

a propane torch will aid in installation.

NOTE: Take care to ensure that all pulleys and spac-

er are piloting correctly and seated flat against

their mounting faces.

NOTE: Two crank pulley spacers are provided in this

system. 4GP017-031 (3.695" long) is to be used

for serpentine drive systems. The 4GP017-041

(3.293" long) is to be used for V-belt applications.

NOTE: The bearing retaining ring on the pulley should

be facing the pulley spacer to properly clear

the “thick” retaining washer. (See Fig. 6-d.)

C. Install all applicable accessory belts at this time

and tension using the appropriate belt tension-

er for your application.

D. (10-Rib Units Only) Lightly grease the super-

charger input shaft and/or the supercharger

drive pulley bore. Install the pulley onto the

supercharger input shaft and rotate the pulley

to align the keyways. Slide the square key into

the keyway. Install the pulley retainer assembly

into the input shaft and hand tighten.

Fig. 5-a: Entry Level V3 6-Rib Application

Fig. 5-b: Entry Level V3 6-Rib Application

M12-1.75 X 50mm

SCREW

"LOW" HEAD

M12-1.75 X 20mm

SCREWS

E.

Locate the manual tensioner assembly:

1. 10-Rib Applications (4GP111-041):

Install the 7/16-20 screw through the

7/16" “thick” washer, tensioner pulley,

pulley spacer and tensioner plate.

Secure using the 7/16"SAE washer

(thinner one) and Nyloc nut provided.

2. 6-Rib Applications (4FA111-032):

Install the M12 x 50mm screw through

the steel dust shield, tensioner pulley,

large diameter pulley spacer, small pul-

ley spacer, and then through the ten-

sioner plate. Secure the assembly

using the M12 nut.