Part 3 - clamps & truck installation, Step 4, Step 5 – TracRac IM T-Rac G2 User Manual

Page 8

TracRac Inc. 994 Jefferson St. Fall River, MA 02721 l 800-501-1578

Instruction Manual

Part 3 - Clamps & Truck Installation

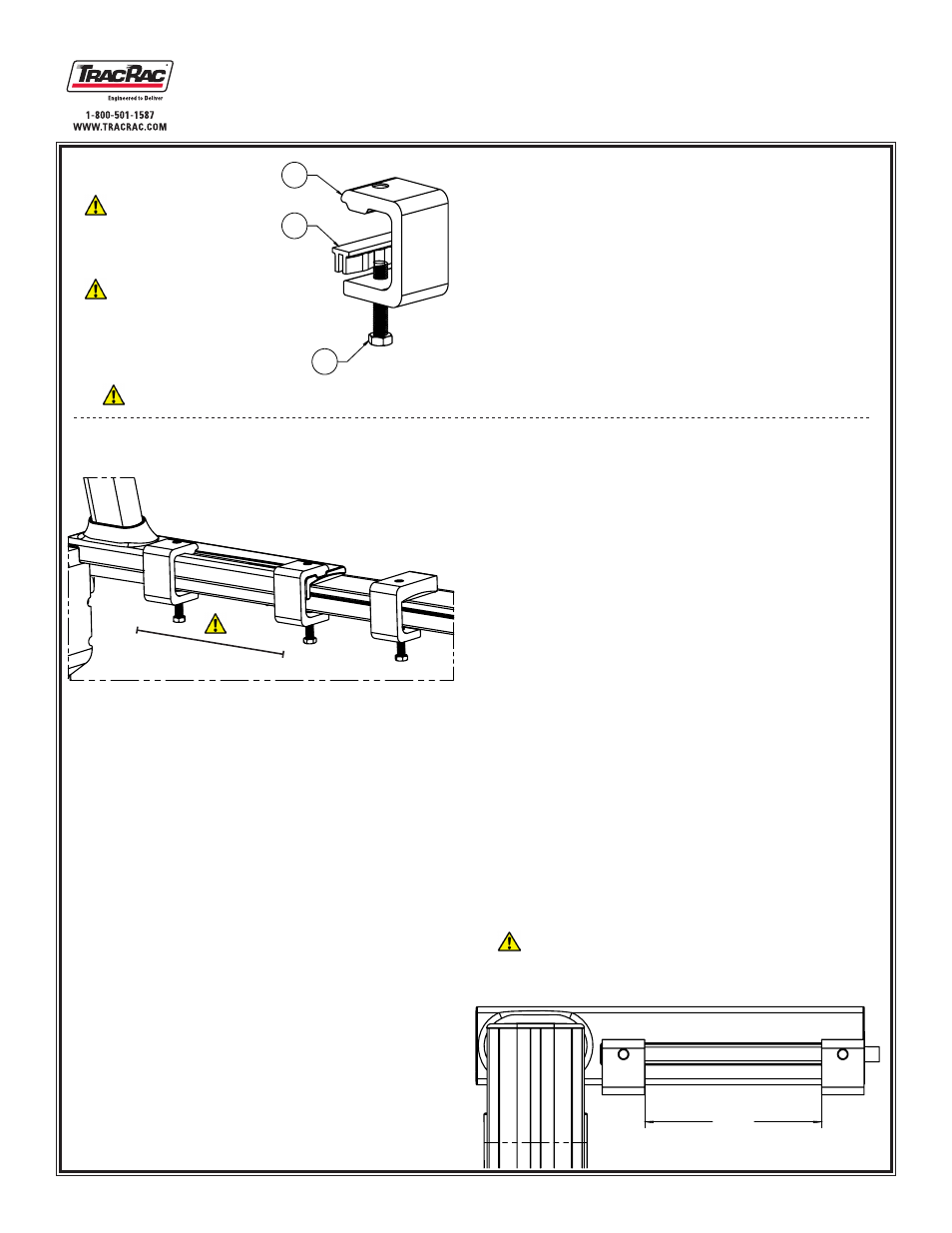

Base Clamp Assembly

Take a TB Front Clamp (Item 4) and thread a 3/8”-16

1.

HHCS (Item 22) through the bottom as shown.

Now take a C channel clamp foot (Item 23) and

2.

place it on top of the 3/8” HHCS as shown.

Repeat steps one and two for the remaining seven

3.

clamps.

Step 4

Front Upright and Base Clamp Assembly

Now take the rounded shims (Item 7) and place

1.

them on the sidewalls of you truck approximately

where the uprights will sit.

The front uprights will be directly behind the rear win-

dow. Place the unit as far forward as possible

Place the front uprights on top of the rounded

2.

shims (Item 7) making sure that the rubber shims

are completely under the bases.

With one pair of uprights now on the truck, they

3.

must be secured using two Modular Clamps (Item

4). When positioning the clamps make sure they

are spaced as far apart as possible.

First torque the clamps on either side of the rack

4.

towards the cab, then follow with the other two

clamps towards the rear of the truck. Torque down

the HHCS to 14 lb-ft using a 9/16” socket and a

torque wrench.

Rear Upright and Base Clamp Assembly

The rear uprights should sit as far towards the tailgate

as possible without the base hanging off the back of

the bed rail, while maximizing the distance between the

clamps (note step 6)

Place the rear uprights on top of the rounded shims

5.

(Item 7) making sure that the rubber shims are

completely under the bases.

With the second pair of uprights now on the truck

6.

they must be secured using two of the previously

assembled (Item 4) clamps (2 per upright). When

positioning the clamps make sure they are spaced

at least 7 5/16 inches apart. Any less of a distance

will reduce the load capacity of the rack. You may

adjust the position of the rack on the bed to ensure

that this distance can be achieved

Repeat step 4

7.

Finally with the uprights secured you now want to

8.

take a measuring tape and center your crossbars.

Once centered use your 7/32” Allen Driver to fully

secure your crossbars. Torque the BHCS to 27 ft-

lbs.

Step 5

Note: clamp feet must be used to ensure proper tension

between the rack and the truck bed and prevent damage

Figure 4.1

n

ote

: B

e

sure

to

keep

the

ruBBer

shim

under

the

Base

when

tightening

the

clamps

max distance possible

Figure 5.1

When tightening the 3/8” button head cap

screws ensure that the Allen Driver is fully seated

in the bolt so that it will not strip

7

5/16

In.

4

23

22

We recommend

that you apply Loc-Tite

(red) to any thread that is

engaged with the clamp.

HHCS (Item 22)

should be re-torqued

every 5000 miles.