Remy 28SI™ ALTERNATOR User Manual

Page 2

NOTICE

- Only licensed Remy International, Inc. product and component parts should be used, and the use of other parts or modifications not approved

by Remy International, Inc. will void all applicable warranties. The failure to carefully follow these Installation Instructions, set forth above, will void all

applicable warranties. DELCO REMY is a registered trademark of General Motors Corporation, licensed to Remy International, Inc. Pendleton, IN 46064.

©

2012 Remy International, Inc. All rights reserved

2

10524210

PHASE (RELAY)

INDICATOR LAMP

EXTERNAL FIELD MONITOR

REMOTE SENSE

(OPTIONAL)

GROUND SCREW (-)

5.6-6.8 Nm (50-60 lb in)

PULLEY INSTRUCTIONS: Use pulley from old alternator if this alternator does not have one or pulley supplied is different from pulley

on alternator being replaced. NOTICE! When changing the pulley, keep the alternator shaft in the horizontal position and do not

apply any pressure to end of the shaft. Internal damage may occur if the shaft is pushed back and turned. All alternators are

shipped with spacers that go behind the pulley. During installation of the pulley, assure these parts are in the same order as

received. If the old alternator has different spacers, use them and Install on this alternator in same order as removed. Assure the

pulley turns freely prior to installation.

Hold the shaft by placing a hex wrench in the hexagonal hole in the shaft while removing or installing the pulley. Tighten the pulley nut

to 95-108 Nm (70-80 lb ft). Do not install the fan.

BELT TENSIONING INSTRUCTIONS: Improper belt tension can cause premature alternator failure. If the belt must

be tightened manually, place a wood block between the alternator and pry bar, as illustrated at right. Pry as close to

the center of the unit as possible. Use a torque wrench to tighten mounting bolts to the proper torque as specified in

vehicle or engine manufacturer’s specifications for belt tension and mounting bolts torque. DO NOT OVER TIGHTEN

BELT!

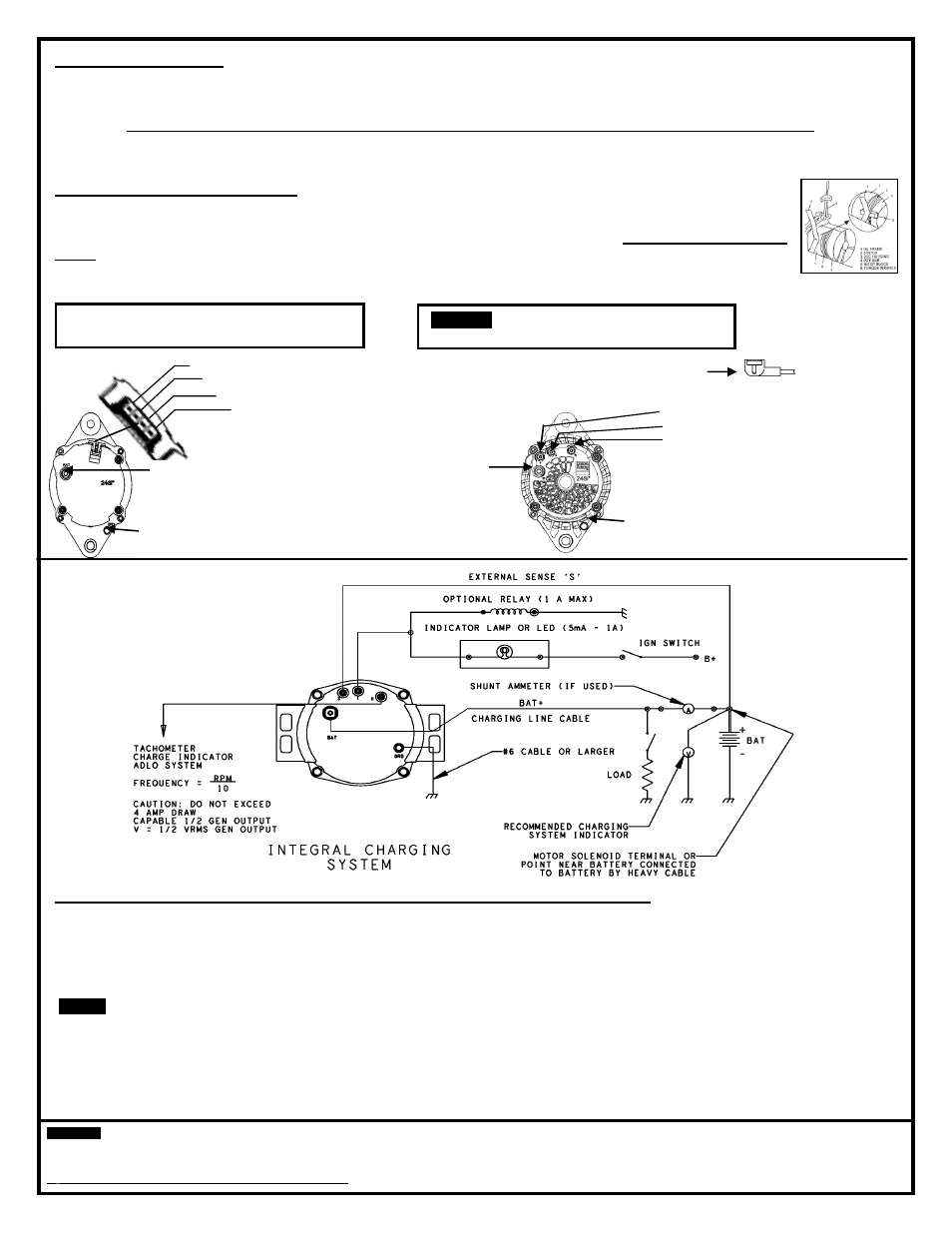

FIGURE 4: TYPICAL WIRING DIAGRAM

FOR STUD CONNECTORS

TERMINAL DESCRIPTIONS (Alternator will function without connecting the S, I or R terminals):

“B+” Terminal - Output terminal connects to the positive (+) battery terminal.

“S” Remote Sense™ Terminal – Connect to system voltage at the battery or a common distribution point.

“R” Terminal – Relay / Phase terminal carries half system voltage and may be used for certain types of control relays, charge

indicators, tachometers or similar devices. The current draw should not exceed four (4) amperes. Frequency = Alternator RPM/10.

Notice!

The “R” Terminal is not the Remote Sense™ terminal – do not connect to B+!

“I” Terminal - The Indicator lamp/ignition terminal can serve as a current source, sink or both, depending on how it is connected. The

diagram above shows one configuration. Current capability is 1.0 Amp in either direction.

Ground Screw

– Ground lead ensures alternator is grounded and is strongly recommended for optimum performance.

RELAY TERMINAL OUTPUT IS

AT 1/2 SYSTEM VOLTAGE

USE PULLEY FROM OLD ALTERNATOR

(SEE PULLEY INSTRUCTIONS PAGE 2

NOTICE!

DO NOT INSTALL AN EXTERNAL

FAN ON A 24SI OR 28SI

ALTERNATOR

FIGURE 3 - 24SI & 28SI (STUD TERIMINALS)

FIGURE 2: 24SI & 28SI (4-PIN PLUG TERMINALS)

REMOTE SENSE

(

OPTIONAL

)

INDICATOR/IGNITION

RELAY (Optional pin terminal)

Three (3) M5 terminals torque

3.0

–5.0 Nm (27-44 lb in)

Three (3) #10 terminals torque

1.7

–2.8 Nm (15-25 lb in)

RELAY PIN TERMINAL CONNECTOR - OBTAIN

FROM DELPHI OR OTHER APPROVED SOURCE

BATTERY (+)

9.0-13.0 Nm

(80-120 lb in)

BATTERY (+)

9.0-13.0 Nm

(80-120 lb in)

GROUND SCREW (-)

5.6-6.8 Nm (50-60 lb in)