Remy REPLACING 25SI REGULATOR User Manual

Remy Generators

Instruction Sheet

10511622

19JL13 C/P30502 REV3

NOTICE

- Only licensed Remy International, Inc. product and component parts should be used, and the use of other parts or modifications not approved

by Remy International, Inc. will void all applicable warranties. The failure to carefully follow these Installation Instructions, set forth above, will void all

applicable warranties. DELCO REMY is a registered trademark of General Motors Corporation, licensed to Remy International, Inc. Pendleton, IN 46064.

©

2012 Remy International, Inc. All rights reserved

1

REPLACING 25SI REGULATOR

WARNING!!!!

ALWAYS USE PROPER EYE PROTECTION WHEN PERFORMING ANY MECHANICAL REPAIRS TO A VEHICLE

–

INCLUDING, BUT NOT LIMITED TO, ANY INSTALLATION AND OR REPAIRS TO THE DELCO REMY ALTERNATOR. FAILURE TO

USE PROPER EYE PROTECTION CAN LEAD TO SERIOUS AND PERMANENT EYE DAMAGE.

Only perform the mechanical functions that you are properly qualified to perform. Mechanical repairs that are beyond your te chnical

capabilities should be handled by a professional installation specialist.

DANGER!!!

To avoid injury or damage, always disconnect the negative cable at the battery before removing or replacing the alternator.

The alternator output terminal is always live (“hot”). If the battery is not disconnected, a tool accidentally touching this terminal and

ground can quickly get hot enough to cause skin burn or damage to the tool and surrounding parts.

The integrated circuit (IC) voltage regulator, base plate, diode trio, and attaching hardware in this package are used to

replace discrete component regulators used in earlier designs of 25SI alternators. The earlier regulators have separate

transistors, diodes and other components mounted on a circuit board covered with an RTV-type coating. Both the new diode trio and the new

regulator must be installed to replace this old type of regulator. New mounting holes must be drilled into the alternator housing to attach the new

components. Use the procedure in this instruction sheet to replace the earlier design discrete component regulator.

In addition to the items supplied in the package and the usual hand tools, a drill with 9/64 inch diameter bit will be needed to complete the installation.

Install regulator and diode trio as follows:

1. Remove four thru-bolts from alternator and separate drive end assembly (with rotor) from rectifier end assembly. This is

necessary to allow complete removal of metal shavings created by drilling holes. Cover the open end of the rectifier end

bearing with tape to keep shavings from getting into the bearing grease.

2. Remove end plate and rectifier cover from rectifier end assembly by removing attaching screws.

3. Remove nuts from rectifier bridge terminals and inside of "R" terminal to disconnect three long, identically colored leads to

regulator. Some units may have a separate lead between the "R" terminal and a rectifier bridge terminal - if so, remove this

lead also. Place nuts loosely back on "R" terminal and on rectifier bridge terminals to hold other leads in place during

repair. If old regulator has a sense lead connected to the heat sink attaching screw (see Fig. 2 for location), remove screw,

flat washer and insulator to disconnect lead. Place insulator, washer, and heat sink screw loosely back into unit for later

attachment of new sense lead. Disconnect two field coil leads from regulator and remove two regulator-mounting screws. Lift

regulator and long leads with grommet from generator housing.

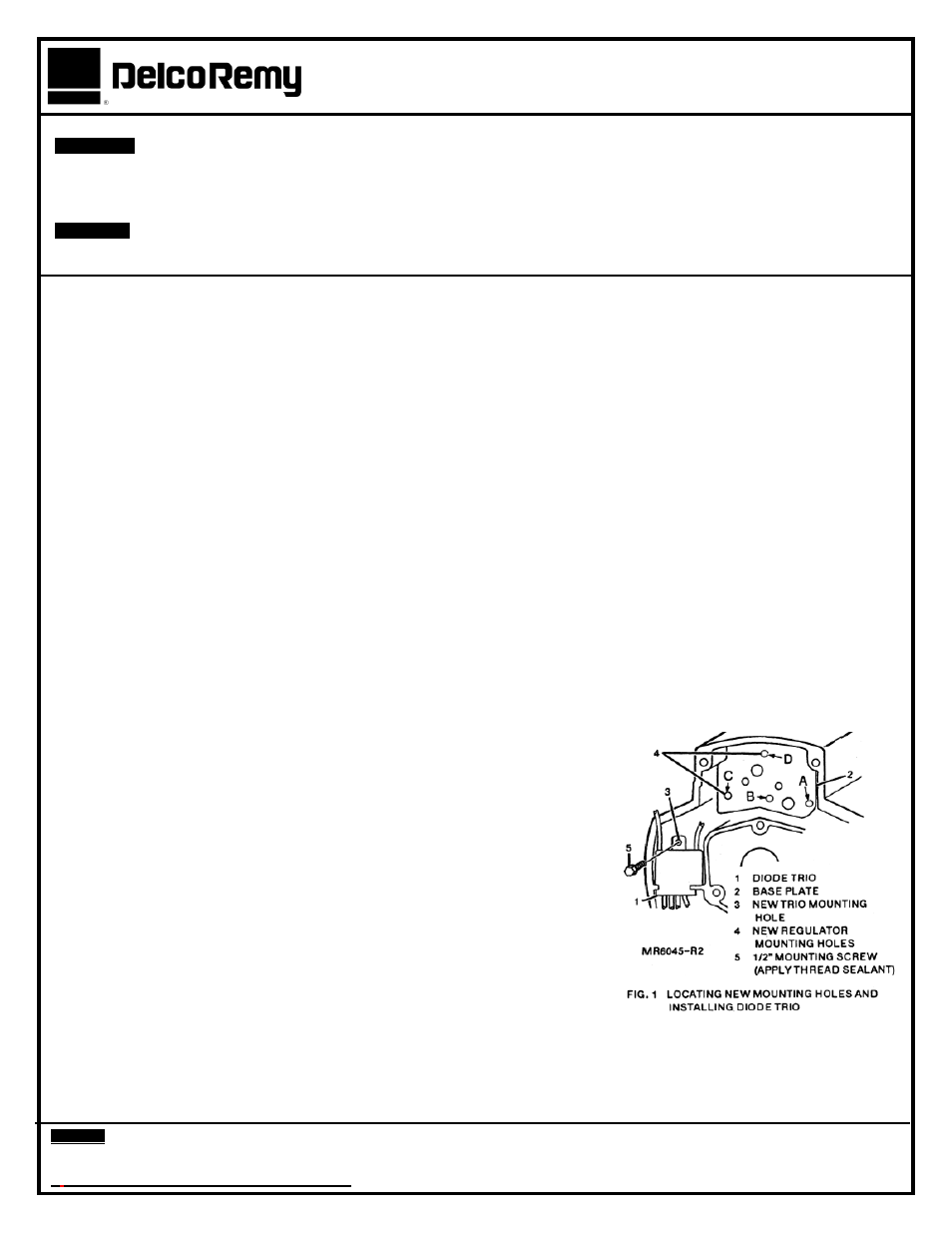

4. See Fig. 1. Place new diode trio and regulator base plate in position as shown.

Locate base plate by positioning mounting hole A over existing mounting hole in

casting. Temporarily install the 1/2” long mounting screw in hole A to hold plate,

aligning edges to be straight with sides of casting. Mark 3 new hole locations (C, D

and E), then remove diode trio and base plate

from housing. Use 9/64” drill bit to

make new mounting holes in housing. Holes C and E will go through housing wall.

Hole D is positioned in thicker cross section and will not go through

– drill 3/4“ deep,

straight into housing material. Remove all traces of metal shavings from both inside

and outside of housing when drilling is complete.

5. See Figs. 1 & 2. Place diode trio into position in housing. Coat threads on 1/2 inch long screw

(in package), with high temperature adhesive/sealant (Loctite

®

620, in package). Secure

diode trio to housing with screw at mounting hole E. Tighten screw in newly drilled mounting

hole to 3.4 Nm (30 lb in). Note: When reinstalling screw in hole previously used,

tighten to 3.0 Nm (26 lb in). This is a grounding screw and must be secure.

6. See Fig. 2. Locate heat sink attaching screw for connecting red diode trio lead.

Remove screw, flat washer, and insulator. Place connector of red lead over hole, then reinstall

insulator, flat washer and screw. Connector of red lead must be under insulator. Tighten screw to 3.0 Nm (26 lb in).