Remy 36SI™ HD ALTERNATOR REPLACEMENT User Manual

Remy Generators

NOTICE

- Only licensed Remy International, Inc. product and component parts should be used, and the use of other parts or modifications not approved

by Remy International, Inc. will void all applicable warranties. The failure to carefully follow these Installation Instructions, set forth above, will void all

applicable warranties. DELCO REMY is a registered trademark of General Motors Corporation, licensed to Remy International, Inc. Pendleton, IN 46064.

©

2012 Remy International, Inc. All rights reserved

1

®

.

33

SI™,

34

SI™,

35

SI™ & 36SI™ HD ALTERNATOR REPLACEMENT COMPONENTS INSTRUCTIONS

These instructions explain how to replace the serviceable components from these assemblies.

NOTE: It is beneficial and possibly necessary to obtain miscellaneous hardware packages for reassembly of these alternators.

It is preferable to use new, undamaged parts.

WARNING!!!!

ALWAYS USE PROPER EYE PROTECTION WHEN PERFORMING ANY MECHANICAL REPAIRS TO A VEHICLE –

INCLUDING, BUT NOT LIMITED TO, ANY INSTALLATION AND OR REPAIRS TO THE DELCO REMY

®

ALTERNATORS. FAILURE TO

USE PROPER EYEPROTECTION CAN LEAD TO SERIOUS AND PERMANENT EYE DAMAGE.

Only perform the mechanical functions that you are properly qualified to perform. Mechanical repairs that are beyond your technical

capabilities should be handled by a professional installation specialist.

DANGER!!!

To avoid injury or damage, always disconnect the negative cable at the battery before removing or replacing the alternator.

The alternator output terminal is always live (“hot”). If the battery is not disconnected, a tool accidentally touching this terminal and

ground can quickly get hot enough to burn skin or damage tools and surrounding parts.

REMOVAL AND INSTALLATION INSTRUCTIONS FOR FAN - ROTOR - DE FRAME (WITH BEARING) - RE BEARING -

DE BEARING - BEARING RETAINER

REFERENCE: There is an exploded parts view of these alternators for easy reference on page 3. Exploded views can usually be found

on tweb site with the service list for these alternators other products

.

1. Remove the pulley nut, pulley and fan. If replacing the fan, dispose of it and go to installation step 5.

NOTICE!

!

Excessive movement may weaken or break a lead or leads between the stator and rectifier assemblies.

2. If replacing the rotor, DE frame, DE bearing or retainer plate, remove the drive end (DE) frame and rotor assembly, by removing

the (4) thru-bolts (mark end frames for reassembly) that hold the end frames together.

3. Separate the rotor and spacer, using a press, from DE frame. If replacing the rotor, save the spacer and dispose of rotor. Install

spacer on new rotor and go to installation step 1.

NOTICE!

!

It is recommended that the DE & RE bearings be replaced when replacing the rotor

4. If replacing the DE frame (with bearing), dispose of it and go to installation step 1

.

5. If replacing RE frame bearing, remove components from frame that can be damaged by pressing bearings out and into the frame.

See instructions in next section for removing and replacing RE components and graphic, on page 3, for correct dimensional

location of bearing in the frame. Go to installation step 2.

6. If replacing the DE bearing, remove the four (4) screw assemblies and bearing retainer plate. Using a press, remove and dispose

of the old bearing and press new bearing into frame bore until seated, by applying force against the outer race only.

7. Reinstall or replace bearing retainer plate. Install and torque the four (4) retainer screw assemblies to 4.5 - 5.7 Nm (40 - 50 lb in).

Go to installation step 1.

INSTALLATION INSTRUCTIONS

1.

Install rotor with spacer into DE frame, using a press.

2.

Assemble the DE and RE frames, being sure to line up the non-threaded mounting lugs or marks. This is best accomplished by

inserting a tolerance pin in the non-threaded holes on hinge mount (J180) units or 2 parallel blocks with pad mount units

.

3.

Install the four (4) thru bolts and torque to 50% of final value. Use a staggered sequence to finish and torque thru bolts to

10.7 - 11.9 Nm (95 - 105 lb).

4.

Reinstall RE cover and four (4) mounting screw assemblies. Torque screw assemblies to 5.7 - 6.8 Nm (50 - 60 lb in).

5.

Install external fan, pulley and pulley nut. Torque pulley nut to 95-108 Nm (70-80 lb ft).

6. Reinstall alternator as noted in engine or vehicle manufacturer’s instructions. See note at end of parts assembly, page 2.

REMOVAL AND INSTALLATION INSTRUCTIONS FOR RE COVER - CAPACITOR -

TERMINAL PACKAGES - DIODE

TRIO - REGULATOR – RECTIFIER BRIDGE – STATOR - FIELD COIL & SUPPORT - RE FRAME

REFERENCE: There is an exploded parts view of these alternators for easy reference on page

3. More detailed exploded views can be

found on tweb site under product support and service parts.

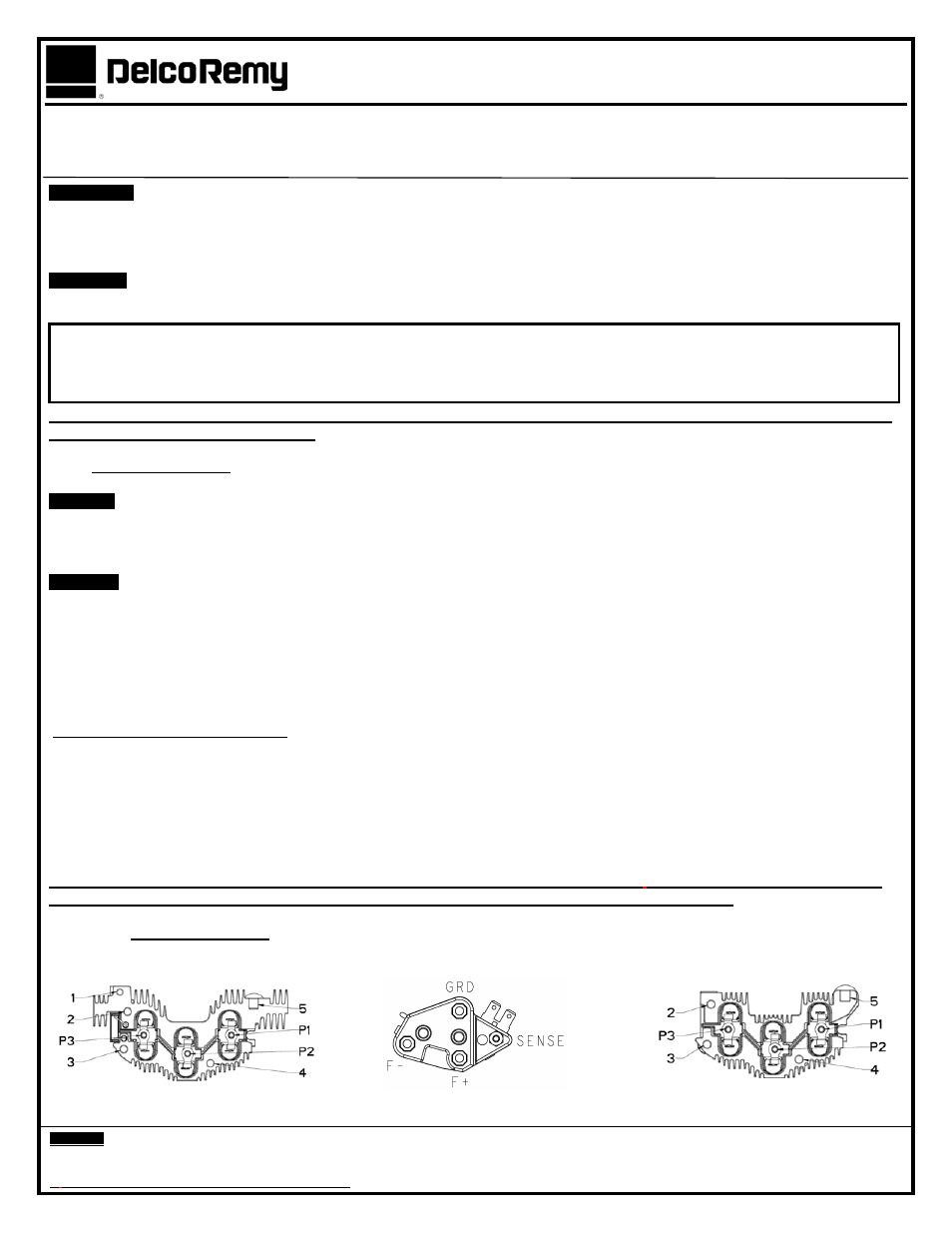

33SI, 34SI, 35SI & 36SI 33SI, 34SI, 35SI & 36SI 33SI & 36SI RECTIFIER BRIDGE

RECTIFIER BRIDGE VOLTAGE REGULATOR (FOR INSULATED MODELS)

NOTE: The rectifiers are different for negative ground and insulated models and connections are different.

The regulator and rectifier terminals are labeled to enable following instructions for replacing components and parts.

INSTRUCTION SHEET

10539634

25NO13 DS07930 Rev0.

FOLLOW ENGINE OR VEHICLE MANFACTURERS INSTRUCTION’S CAREFULLY WHEN REMOVING AND REINSTALLING THE

ALTERNATOR.

♦

Disconnect the negative (-) cable at the batteries.

♦

Remove vehicle leads connected to the alternator, noting their positions for reinstallation of the alternator.

Document Outline

- 33SI™, 34SI™, 35SI™ & 36SI™ HD ALTERNATOR REPLACEMENT COMPONENTS INSTRUCTIONS

- NOTICE!! It is recommended that the DE & RE bearings be replaced when replacing the rotor

- INSTALLATION INSTRUCTIONS

- NOTE: The rectifiers are different for negative ground and insulated models and connections are different.

- The regulator and rectifier terminals are labeled to enable following instructions for replacing components and parts.

- INSTALLATION INSTRUCTIONS

- 33SI™, 34SI™, 35SI™ & 36SI™ SERVICE PARTS