Vessels with an o-ring seal, Vessels with a flexible graphite gasket, Vessels with a metal gasket – Parr Instrument 4700 User Manual

Page 8: General purpose pressure vessels

General Purpose Pressure Vessels

P a r r I n s t r u m e n t C o m p a n y

8

Vessels with an O-ring seal

The self-sealing design features an O-ring retained

in a groove on the vessel head. This design is self

sealing and the split ring does not require or have

the compression bolts used with the flat gasket.

Vessels with a Flexible Graphite Gasket

The closure bolts may be tightened using either an

open-end wrench for smaller vessels where the bolt

torque requirement is less or with a torque wrench

where additional loading is required for the higher

operating pressures.

Some of the gasket numbers shown in the attached

table are furnished with vessels that have different

maximum working pressures. We have shown the

maximum torque value to correlate to the maximum

working pressure of the vessel.

It is important to make sure that the bolts are

periodically lubricated with a high-temp anti-seize

compound to insure that they move freely so that

the desired torque value is obtained in the tighten-

ing procedure.

It is also important to insure that there is uniform

loading on all of the bolts. Make sure that the head

sits levelly on the cylinder. Install the split ring and

tighten all bolts finger tight.

Pick a starting position and tighten the bolt to 5 or 10

ft-lbs depending on the maximum amount of torque

to be applied. For those vessels with a maximum

torque requirement of 15 ft-lbs, a 5 ft-lb increment

is appropriate. For vessels with a maximum of 135

ft-lbs, 20 ft-lb increments may be used.

Bolt tightening should continue in a criss-cross

pattern from the initial bolt with the second bolt 180

degrees from the first and continuing until all bolts

are tightened. Repeat this procedure increasing the

torque to the required level as shown in the table

below.

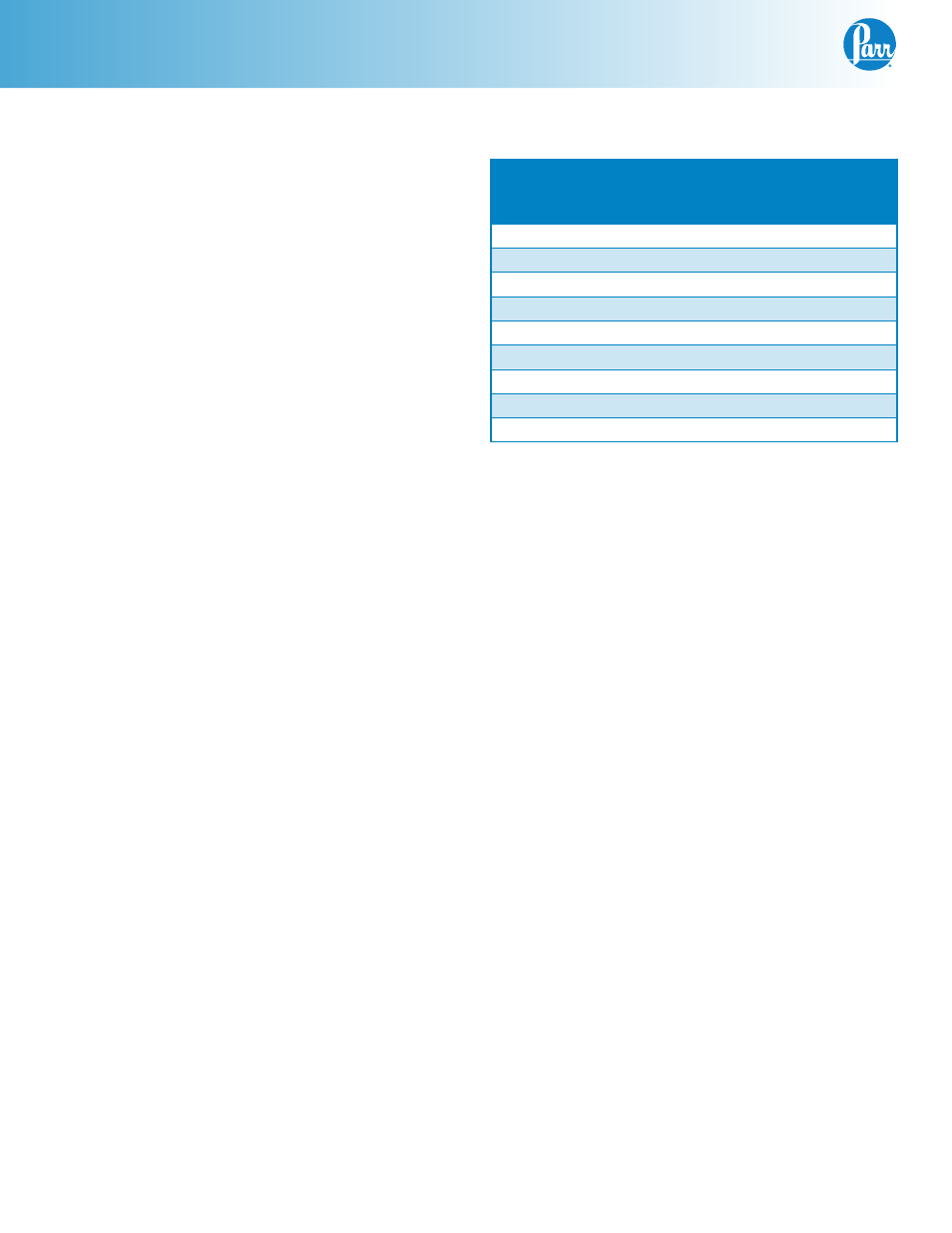

Torque Required For Sealing Vessels

with Flexible Graphite Gaskets

Vessel

Series

No.

Maximum

Working

Pressure, PSI

Graphite

Gasket

No.

Torque

Required

ft-lb

4600

1900

315HC4KL

35

4790

3000 to 5000

429HC2KL

15

4760

3000

457HC3KL

35

4650

5000 to 6000

457HC3KL

40

4660

1900

655HC3KL

35

4680

5000

1808HCKL

40

4670

3000

1812HCKL

35

4740

8500

1829HCKL

15

4676

1900

1559HC2KL

135

Note:

It may be possible to extend the life of

the Flexible Graphite gasket by coating both

sealing surfaces of the head and cylinder as

well as the gasket itself with a silicone base

lubricant. Additionally, it helps to rough up

the cylinder lip with 120 grit sandpaper to

insure that the gasket remains in the head

recess and does not stick to the cylinder.

Vessels with a Metal Gasket

Pressure vessels with a metal gasket require a

uniform loading on the gasket carefully applied by

tightening a ring of compression bolts with a torque

wrench. The amount of torque to be applied will

vary with different vessels and with the intended

maximum working pressure. Specific sealing

instructions will be provided for any Parr pressure

vessels with a metal gasket furnished on special

order.