Parr pressure vessel seals, Flat gasket or self sealing o-ring closure, Seals for operating temperatures up to 350 °c – Parr Instrument 4700 User Manual

Page 7: Gaskets for operating temperature above 350 °c, Sealing the vessel, Vessels with a flat ptfe gasket, General purpose pressure vessels

General Purpose Pressure Vessels

w w w . p a r r i n s t . c o m

7

PARR PRESSURE VESSEL SEALS

Several different head sealing arrangements are

used in Parr Pressure Vessels, each selected for easy

access to the interior of the vessel as well as for

safe operation within the pressure and temperature

limits for which the vessel is designed. Both flat

compression type gaskets and O-rings are used in

these designs.

The various gasket materials used in Parr pressure

vessels are listed in Table I. Since several of these

materials are produced by different suppliers under

different trade names, the ASTM generic designa-

tion is used in these instructions to identify the type

of sealing material (or materials) recommended for

each Parr vessel.

Flat Gasket or Self Sealing O-ring Closure

The flat gasket is held in a recess in the vessel head

and a machine pilot on the cylinder closes the recess

to completely contain the gasket. The split ring clo-

sure used with this gasket has cap screws which must

be tightened to develop the loading on the gasket.

The self sealing design features an O-ring retained

in a groove on the vessel head. This design is self

sealing and the split ring used with this sealing

system does not require nor have the cap screws

used with the flat gasket.

The flat PTFE gasket can be used to operating tem-

peratures as high as 350 °C. The flat flexible graphite

(FG) gasket can be used to operating temperatures

as high as 600 °C.

The maximum temperature of the vessels equipped

with O-ring seals depends upon the material used

for the O-ring. The most common material is a fluo-

roelastomer (FKM) which has a 225 °C maximum

operating temperature limit.

Seals for Operating Temperatures up to 350 °C

Parr uses both flat contained gaskets and O-rings

made of different materials, each with a different

maximum working temperature. Flat gaskets made

of PTFE fluoropolymer resins are the recommended

choice for many applications since PTFE materi-

als are inert to most chemicals. PTFE gaskets will

provide good seals under repeated opening and

closing of the vessel if the gasket temperature does

not exceed 350 °C.

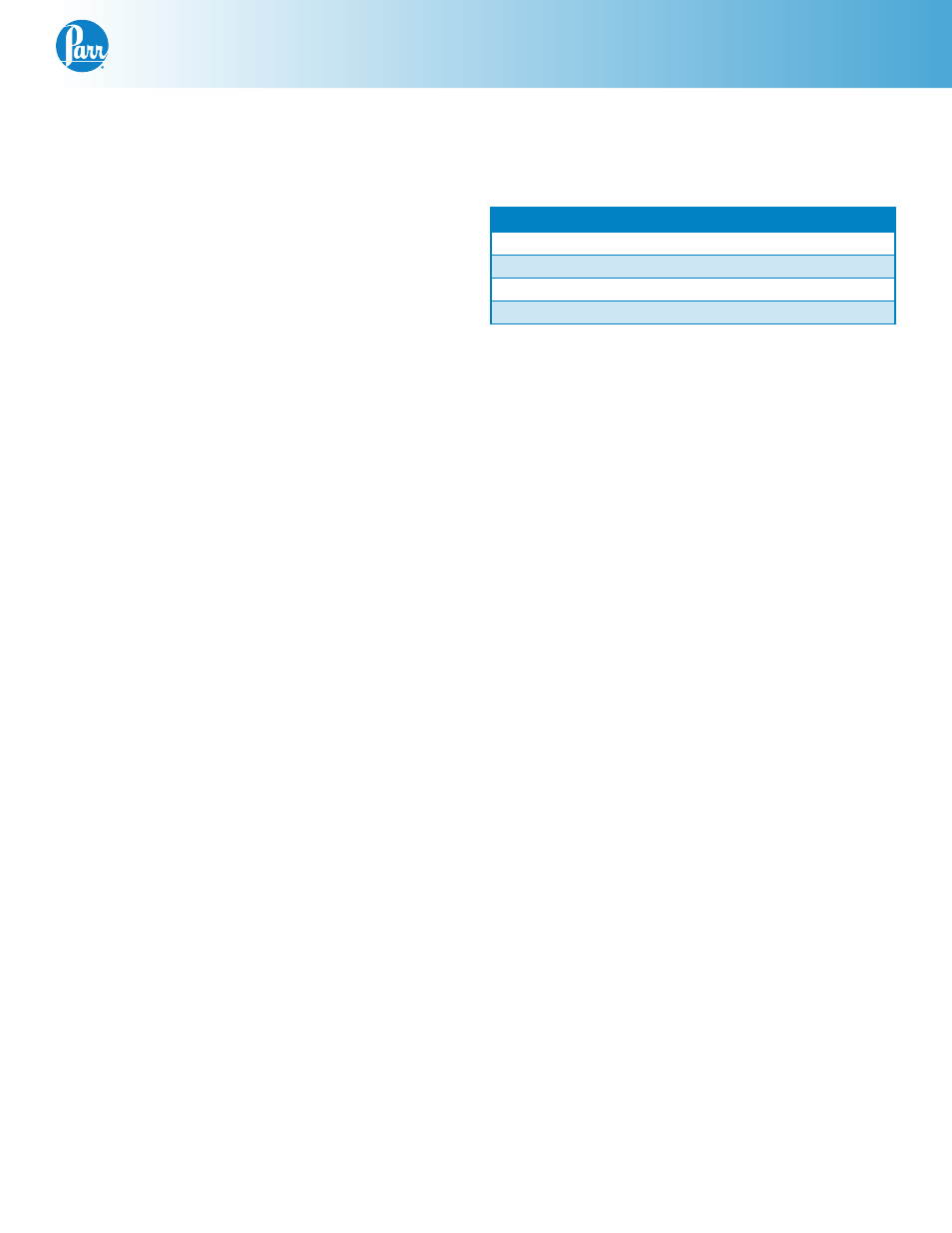

O-rings are available in several different materials

for use within the temperature limit listed in the

following table.

Pressure and Temperature Limits

O-Ring Material

Maximum Temperature

NBR

150 °C

FKM

225 °C

FFKM

300 °C

PTFE

350 °C

Gaskets for Operating Temperature above 350 °C

Parr uses a flexible form of graphite which has

proven to be an excellent high temperature sealing

material. It has almost unlimited temperature range,

retaining its structure at temperatures well above the

maximum at which a metal gasket can operate, and

offering broad corrosion resistance as well.

Metal Gaskets can be furnished if required for special

applications. These are usually made of stainless

steel machined to a unique diamond shape with

edges which fit into supporting grooves in the head

and cylinder of the vessel. This type of gasket re-

quires careful maintenance and a uniform loading ap-

plied by tightening a ring of compression bolts with a

torque wrench. For easier handling, Parr has replaced

its diamond shaped metal gaskets with flat, flexible

graphite gaskets (FG) described above. But it will

continue to furnish metal gaskets in custom vessels

for applications in which a metal gasket appears to

offer the best solution to a difficult sealing problem.

Sealing the Vessel

Vessels with split ring closures are sealed by tight-

ening the compression bolts in the split ring sec-

tions with a wrench furnished with the apparatus. To

ensure uniform loading, turn down each bolt finger

tight, then tighten to the limit described below for

the type of gasket being used. Do not over-tighten

the compression bolts as this can generate exces-

sive strain on the closure.

Vessels with a Flat PTFE Gasket

Tighten the compression bolts using a criss-cross

pattern, applying a firm but hard pull to each

screw. Use a torque wrench to apply 25 ft-lbs to

each compression bolt. Let the vessel stand for

about five minutes after the initial tightening, then

tighten again to 25-ft lbs. This will compensate for

any tendency of the PTFE gasket to flow under the

loading pressure.