Ntellisys, Alve, Odels – Nor-Cal Intellisys TSS User Manual

Page 12: 3 - troubleshooting

12

12

Visit our Web Site

www.n-c.com

I

ntellIsys

s

oft

s

hut

TM

G

ate

V

alVe

M

odels

TSS-OP-LiT 08/11

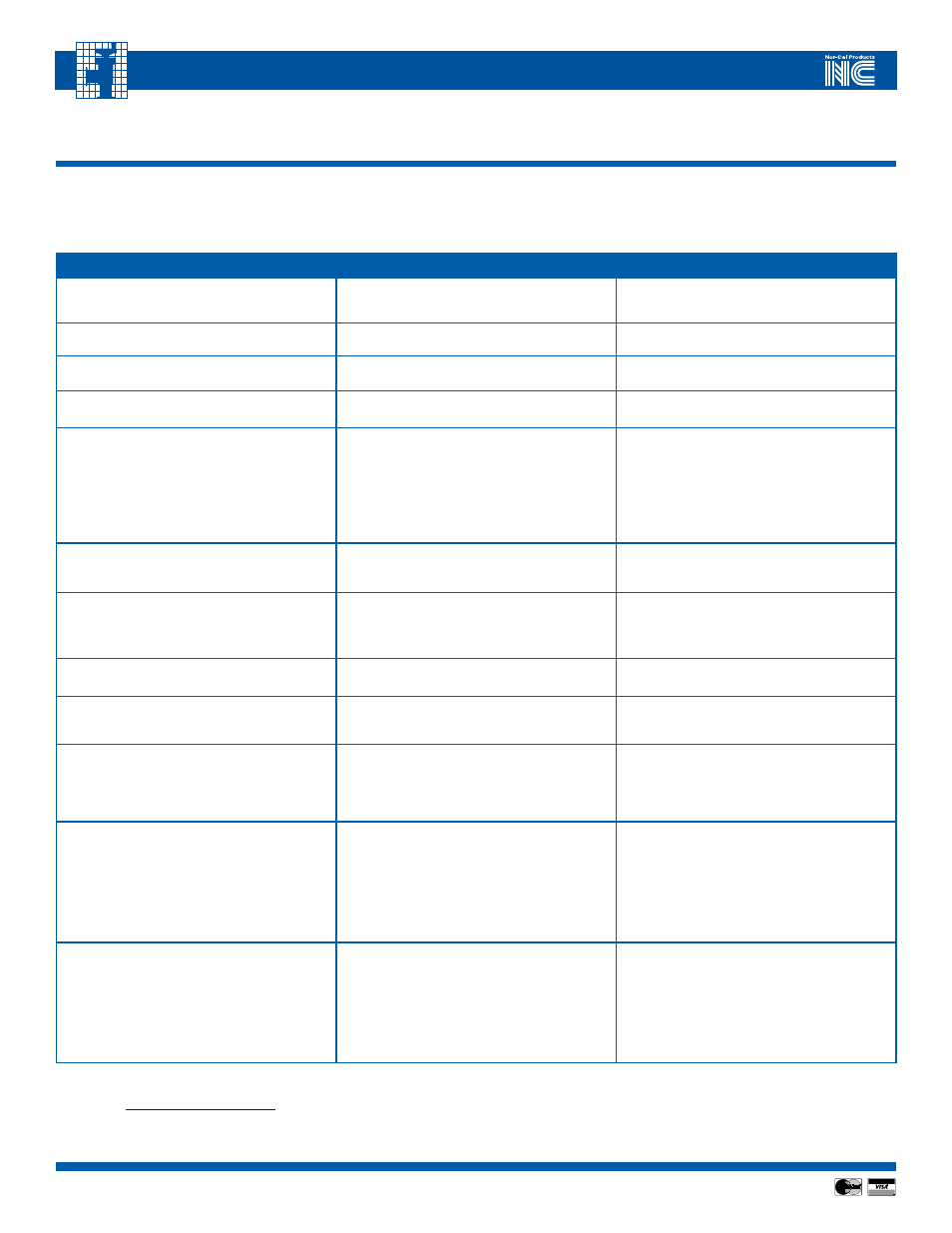

5.3 - Troubleshooting

Some basic troubleshooting can be done by the user referring to the instructions and suggestions below. Table 5.3 describes possible

symptoms and recommended actions.

TAbLE 5.3 – pOSSIbLE FAILURE mODES AND RECOmmENDED ACTIONS

Symptom

possible Causes

Recommended Action

The TSS valve does not appear to turn on or oper-

ate.

The TSS is not connected to the controller module

(standard TSS models only)

Check to make sure the controller-to-valve cable

is connected at both ends, using the correct con-

nectors.

The controller-to-valve cable is faulty (standard

TSS models only)

Try another TbV-CRD-XX cable.

The controller module is not on, or is faulty.

Check controller module and refer to appropriate

controller Operating Manual

The Oldham coupling is broken

Turn off controller power. Remove motor drive to

inspect Oldham coupling

The TSS appears to operate but pressure- or posi-

tion control is inconsistent and poor

The valve gate is jammed or partially jammed in

the valve bore.

Turn off controller power and remove the motor

drive from the gearbox. Attempt to move

the gearbox input shaft by hand. If binding is

observed, remove valve from system to deter-

mine the root cause. Clean off process residue as

necessary using a non-abrasive method. If dam-

aged parts are found, contact Nor-Cal Intellisys

Customer Support

The Oldham coupling disk is worn or cracked

Turn off controller power. Remove drive unit from

gearbox. Replace the Oldham coupling disk as

necessary.

A whining or buzzing sound is heard from the TSS

motor drive

The Oldham coupling disk, or possibly hubs, is

loose or worn and a harmonic resonance point has

been excited

Turn off controller power. Remove drive unit from

gearbox. Replace the Oldham coupling disk as

necessary. If problem persists, contact Nor-Cal

Intellisys Customer Support.

The controller motor control coefficients have

been corrupted.

Turn off controller power. Turn back on and allow

initialization sequence to complete

The wrong controller is being used.

Note model and serial number of valve and con-

troller and contact Nor-Cal Intellisys Customer

Support

The motor and valve shaft rotate continuously in

one direction without stopping and without mov-

ing the valve gate

The square key between the rotary shaft and

gearbox is missing or broken.

Remove the rotary indicator disk, spacer and

screw. Remove the four screws holding the gear-

box to the valve. Slide off gearbox / motor assem-

bly from rotary shaft and inspect key and shaft

keyway. Replace items as necessary.

The gate actuation arm is broken or otherwise

decoupled.

Turn off vacuum system. Open the bonnet cover

by loosening the bolts on back plate. look inside

to inspect short gate arm that links the rotary

shaft to the gate and carriage mechanism. NOTE:

It is impossible to move or turn the shaft with

the gearbox attached. If manual operation is

required, then removal of the gearbox is neces-

sary (see step above).

The valve has developed a leak to atmosphere

along the valve shaft

O-ring damage and/or loss of vacuum grease can

cause this

Follow steps above to open bonnet cover AND

remove gear head. Remove the square and plates

found under the gearbox, and remove the short

gate arm attached to the shaft. Pull shaft out

from bearing and seal cavity (this may require a

tool (Please contact Nor-Cal Intellisys Customer

Support to obtain instructions). Visually inspect

the seal, relubricate or replace as necessary.

Global Sales and Service

: Nor-Cal Products maintains sales and service centers in over 30 countries worldwide. Please visit our

website at

http://www.n-c.com

to find the center nearest you.