Setting the closed positions, Step 28, Step 29 – Mighty Mule FM702 User Manual

Page 29: Step 30, Step 31, Step 32, Step 33, Step 27

25

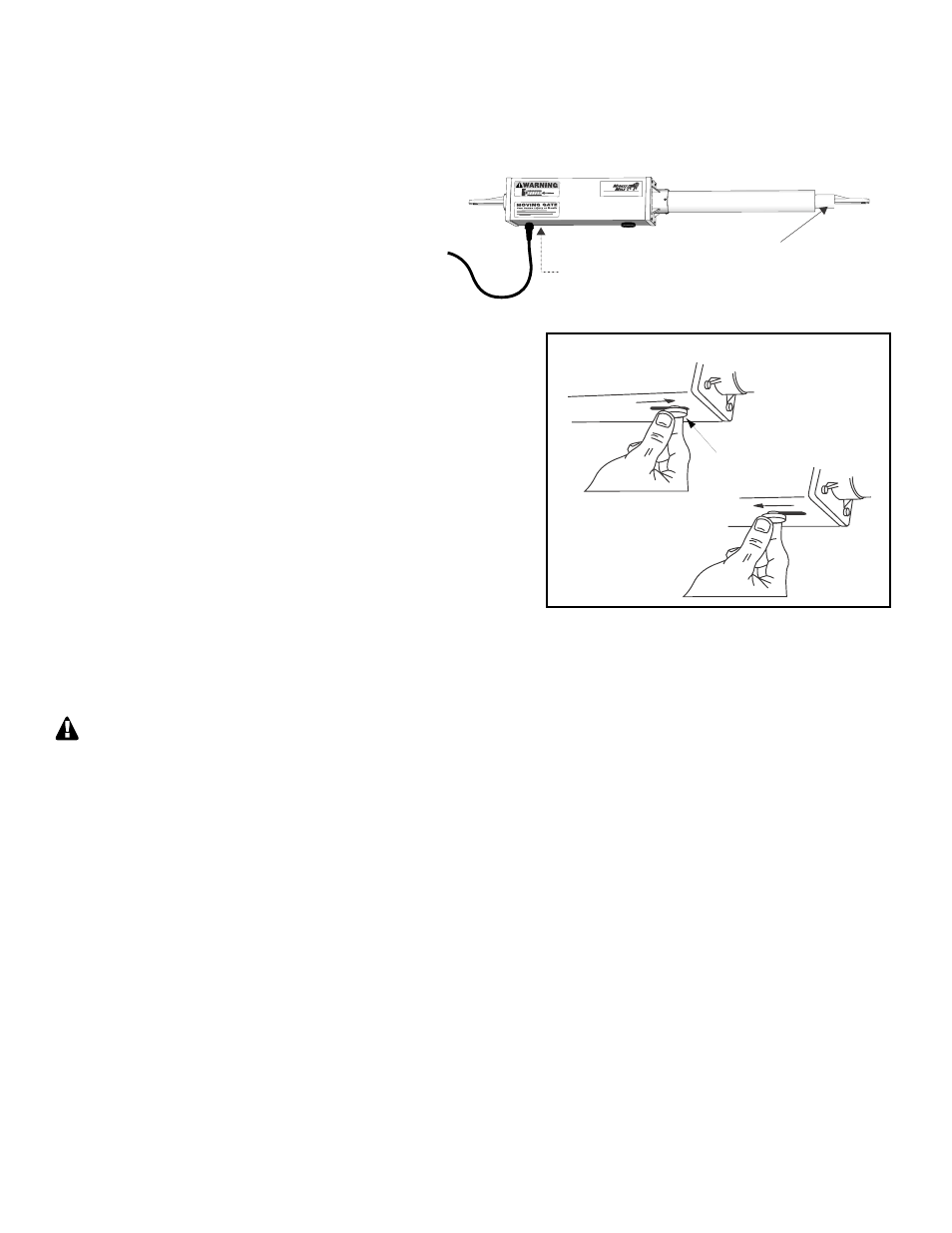

Step 28

Reattach front mount to gate bracket using a clevis pin, washer, and

hairpin clip. Press the transmitter button to activate the opener and

determine the degree of gate closure. Initially, the push-pull tube

will extend only 7-1/2" until the stroke adjustment knob is set

(see below right). The maximum extension of the push-pull tube is

11

1

/

2

".

Step 29

To increase the degree of gate closure, loosen the stroke

adjustment knob on the bottom of the opener housing and move it

approximately

1

/

8"

toward the gate bracket (see Fig. A). Finger

tighten the knob (DO NOT USE PLIERS OR OTHER TOOLS

TO TIGHTEN KNOB). Press the transmitter button to check your

adjustment. To decrease the degree of gate closure, move the stroke

adjustment knob away from the gate bracket (see Fig. B).

Step 30

Repeat the procedure in Step 27 until the gate closes firmly as the opener motor shuts down. Each time you adjust the knob,

finger tighten it before pressing the transmitter button to check your adjustment.

If the push-pull tube has been extended too far (i.e., if the knob is too close to the gate bracket), the gate will immediately

reverse and open after closing. When the knob setting is correct, the gate will close firmly, but not sharply, against the

positive stop plate. The motor will run for one-half second after the gate closes against the stop plate. If the motor continues

to run for more than one second, the push-pull tube is overextended and further adjustment is necessary. If the motor strains

too long against the stop plate, the fuse on the control board (above OPERATOR terminal) will be blown. This blade-style

15 ampere fuse (sold by most automotive supply stores) can be easily replaced. NEVER use a fuse rated higher than 15

amperes!

Step 31

Turn the control box power switch OFF. Disconnect the power cable plug from the coupling of the SLAVE operator with

the gate in the fully closed position (do not disconnect the stripped ends on the power cable from the SECOND

OPERATOR terminal block).

Step 32

Repeat Step 25 through Step 28 to connect the 4-1/2 foot power cable and set the closed position for the MASTER gate

leaf. After you have set the closed position for the MASTER gate leaf, bury the PVC conduit and use the appropriate

material to patch the slot in the driveway.

Step 33

Turn the control box OFF and reconnect the power cable plug and the SLAVE operator. Turn the control box ON and retest

the stroke adjustment and sequencing of your dual gate with both openers activated. Make fine adjustments to the stroke

knob position and set the SEQ1 and SEQ2 DIP switches if necessary. NOTE: Only make changes to the DIP Switches when

the Control Box is turned OFF.

Stroke Adjustment Knob

Figure A

Moving knob toward

the gate bracket

increases gate closure.

Figure B

Moving knob away

from the gate bracket

decreases

gate

closure.

Step 27

Carefully insert the power cable plug (of the

SLAVE power cable) into the coupling at the rear of

the opener. Turn the plug until it aligns with the

pins in the coupling. Push the plug into the

coupling until it stops. Finger tighten the sleeve nut

to lock the plug into position.

®

E-Z GATE OPENER

Push-Pull Tube

Attach Power Cable Plug

Setting the Closed Positions

HINT: The easiest way to make sure your dual gate closes fully is to set the closed position for each gate leaf one at a time.

Set the closed position for the SLAVE gate.