8 maintenance and service – Martin Christ Epsilon 2-6D LSCplus User Manual

Page 101

Freeze-dryer EPSILON 2-6 LSCplus

8 Maintenance and service

Version 10/2012, Rev. 1.6 of 16/12/2014 • sb

101

Translation of the original operating manual

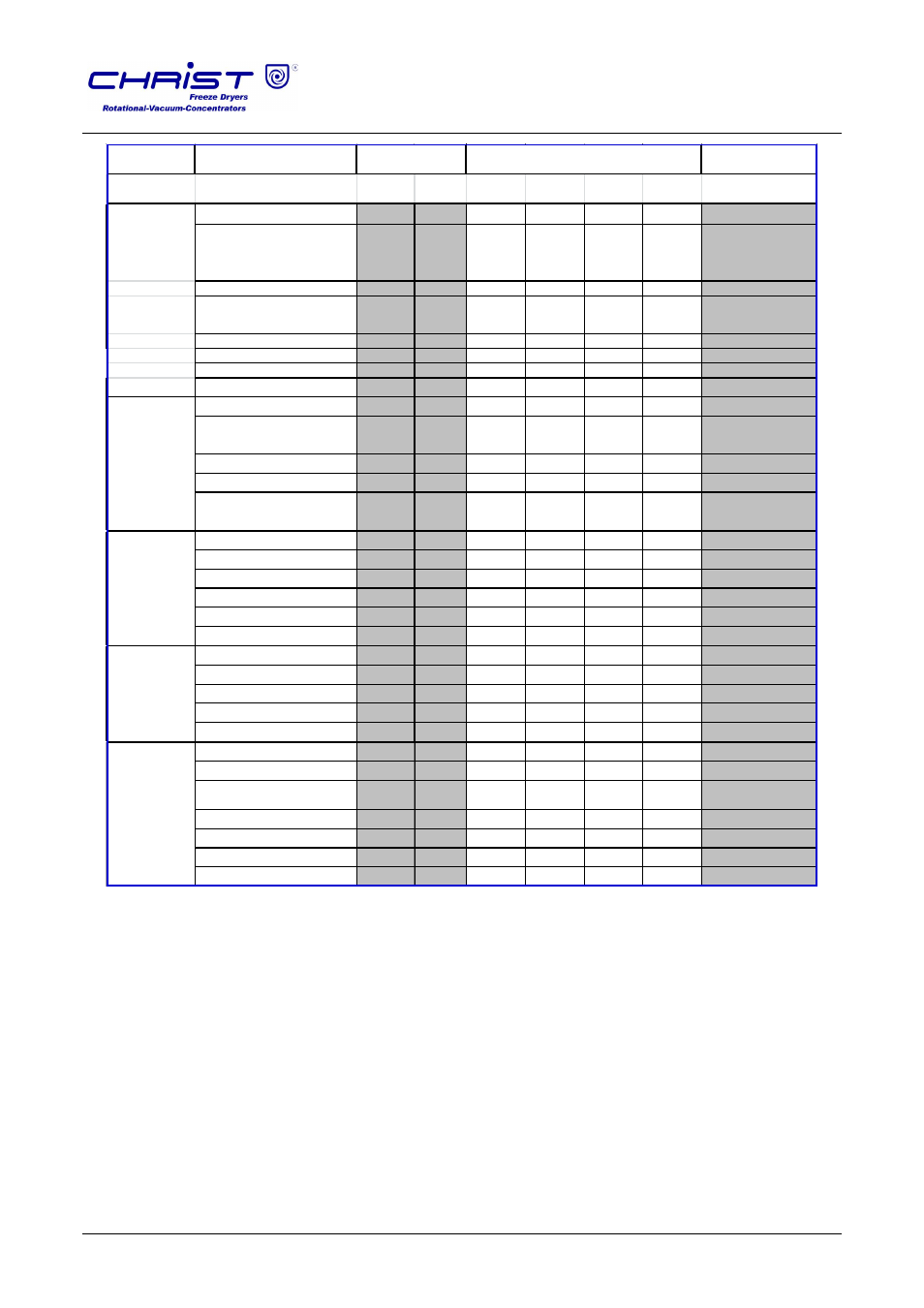

System/

Component

Detail / Part

Remarks

before

start

daily

inspection

replace

operation calibration

Ice formation

X

Leakage test according to EU

842/2006

(with more than 3 kg refrigerant)

Heat exchanger

X

cleaning

Pressure readings / performance

tests

X

Noise emission above average

X

Soleniod valves

X

Ice condenser temp.: low end

X

Cooling water control valves

X

X

Clean regulation device

Expansion vessel: liquid level

X

X

X

Soaked insulation

by silicone oil

X

X

Trigger point over temperature

X

Temperature gages: positioning

X

Drying cartridge

(adsorption filter)

X

Vacuum sensor(s)

X

Temperature points at FD

X

Pressure sensors chamber

X

Product temperature

X

X

Changing procedure

Level switches

X

Solenoid valves

X

X

Leakages

X

X

Max pressure reading

X

Oil in reservoir

X

X

Hydraulic hoses

X

after 5 years

Travel speed cylinder

X

Cabinet: temperature inside

X

X

Cabinet: components

X

Cabinet: cooling system

X

Filter

after 1 year

X

Wiring

X

Power reading of components

X

PLC backup battery

2 years

Alarm system (horn, light)

X

Inspection

Periodical Maintenance

Electrical

Installation

Hydraulic

System

Liquid System /

Silikon Oil

Circuit

Instrumentation

Refrigeration

System

Pos: 219 /01 0 Univ ersal mod ule/Seit enwec hsel @ 0\m od_ 120 211 624 4312 _0. docx @ 10 5 @ @ 1