Lingenfelter L460160000 Lingenfelter RPM-003 RPM Activated Switch Instructions v1.5 User Manual

Page 4

Page 3 of 17

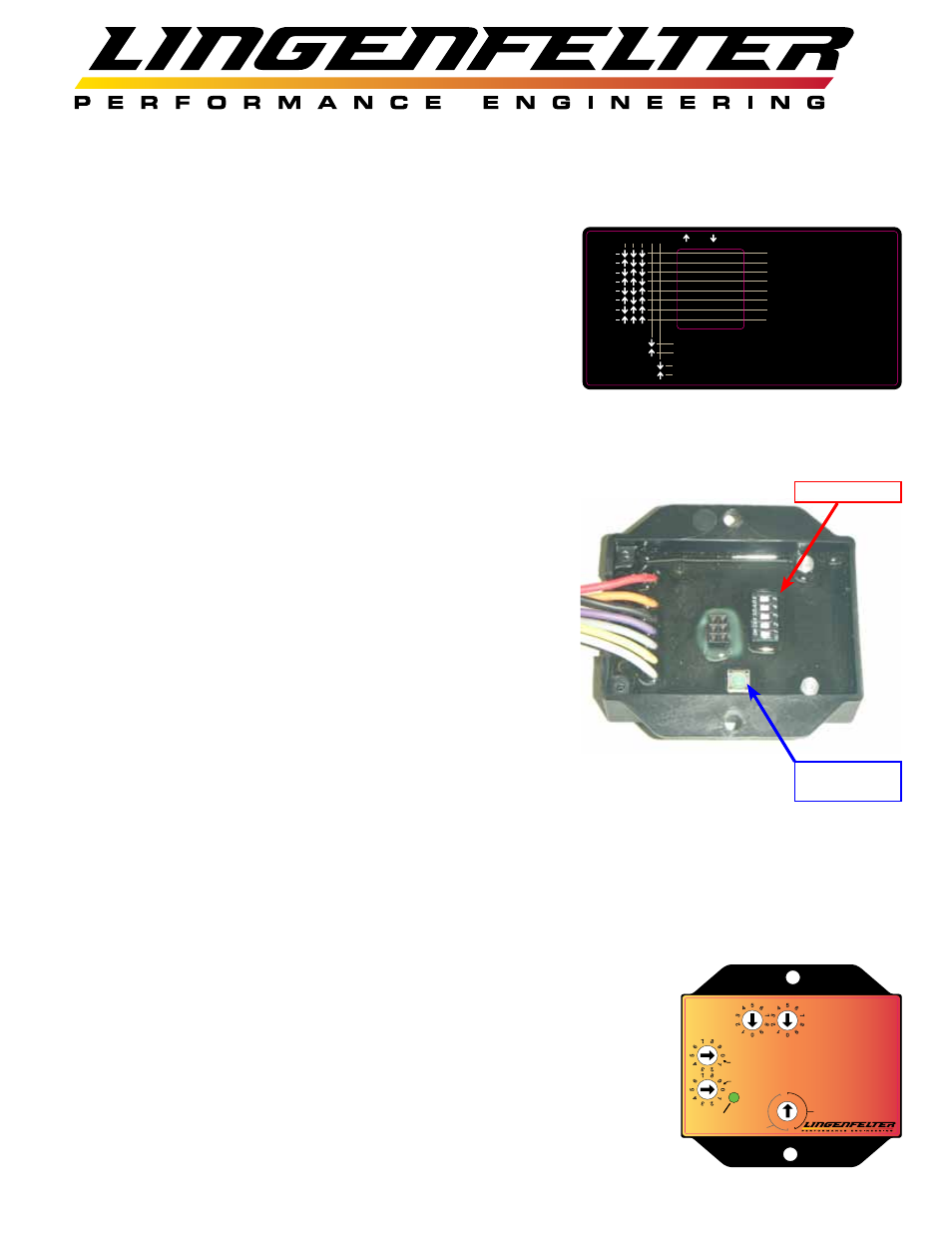

Settings inside the rear cover of the RPM-003:

• Five two position DIP switches (The location of these switches are shown in

Figure 2.)

• DIP switches #1-3 select desired RPM hysteresis (The hysteresis DIP

switch settings are shown in Figure 1.)

• The RPM-003 features RPM hysteresis settings of 0, 50, 100, 150,

200, 250, 300, and 350 RPM.

• When an RPM hysteresis is enabled, the RPM-003 will still switch

at the RPM set point (which is set by the RPM #1 and/or RPM #2

settings), but the RPM-003 will not switch again until the set point

and the hysteresis is reached. (i.e. RPM-003 will switch at 4500

RPM but will not switch back until engine speed falls below 4300

RPM due to a 200 RPM hysteresis).

• It is recommended to use at least a small amount of hysteresis as it

is possible for the RPM-003 to continually switch the outputs on

and off if the RPM is held at the user-defined RPM switch point

with no hysteresis.

• DIP switch #4 toggles analog input ON or OFF (fixed at 90% trip point

with 2% hysteresis)

• This option can be used to activate the outputs on the RPM-003

based on a 0-5 volt analog input signal from the following vehicle

sensors:

• Throttle Position Sensor (TPS)

• Clutch Pedal Position (CPP) sensor

• Accelerator Pedal Position (APP) sensor

• Manifold Absolute Pressure (MAP) sensor

• Or any other rising or falling 0-5 volt signal

• When this option is enabled, the outputs will not activate until

both the RPM set point and the analog input trip point have been

reached.

• This function can be used in nitrous applications to prevent nitrous

oxide from being released prematurely (before BOTH the RPM set

point and analog input trip point has been reached)

• Dip switch #5 toggles the built in tachometer pull-up resistor ON or OFF

• This option is normally used when connecting to the engine speed signal output from the ECM through a

circuit that does not have a pull-up resistor installed. On vehicles that already have this signal connected to

another system or module, a pull-up resistor is most likely already present in the circuit. You DO NOT want

to have multiple pull-up resistors in the circuit. Vehicles that have a pull-up resistor in the instrument cluster

(such as C5 and C6 Corvettes) will require the RPM-003’s pull-up resistor feature to be disabled as it will

create too much resistance in the circuit. Vehicles that do not have a pull-up resistor in the instrument cluster

(such as 2010-2013 Camaro and 2007-2012 CK trucks) should have this feature enabled if you plan to connect

to the ECM signal source.

• ONLY use the tachometer pull-up setting when connected to a TACH signal.

Enabling this when connected a coil or injector may cause a check engine light

and/or a misfire to occur.

• One push button (The location of this button is shown in Figure 2.)

• Used to program the analog input voltage range when device is in programming mode

• In order for the device to enter programming mode, all four 10 position switches must

be set to zero and the 16 position switch must be set to 0.5, low range (arrow pointing

straight up). See illustration on the right for switch positions.

1 2 3

ON

OFF

0

1

2

3

4

5

6

7

RPM HYSTERESIS

0 RPM - HYSTERESIS OFF

50 RPM

100 RPM

150 RPM

200 RPM

250 RPM

300 RPM

350 RPM

4 5

SWITCH #4

SWITCH #5

ANALOG INPUT OFF

ANALOG INPUT ON

TACH INPUT PULL-UP RESISTOR OFF

TACH INPUT PULL-UP RESISTOR ON

DIP Switches

Programming

Button

Figure 1: DIP switch settings label

(also found on the backside of the

RPM-003 back cover).

Figure 2: Location of components

inside the RPM-003’s back cover.

Power

RPM-003

RPM Window Switch

Ground - Black

Normally On - Gray

Normally Off - Yellow

with Analog Input

RPM #1 x1000

RPM #1 x 100

+12V Switched Power - Red

RPM #1

RPM #2 x1000

RPM #2 x100

RPM #2

Analog Input Signal - Purple

+12V Output Norm Off - Orange

Tach Input Signal - White

.5

1

2

3

4

5

1.5

2.5

.5 1

1.5

2

2.5

3

4

5

High Range

+10,000 Off Rpm

Low Range