Hase Ottawa User Manual

Page 38

38

5.

Flue Pipe Connection

The stove has to be connected to the chimney with

a flue pipe with an inside diameter of 15 cm. Please

ensure that all pipe pieces are tightly fit at the con-

nection junctions. We recommend using elbow pi-

pes with cleaning hatches.

CAUTION!

The flue pipe must be well sealed at the

chimney entrance and cannot project into

the inner cavity of the chimney; otherwise

the flue gas venting will be impaired (Fig.

1).

fig. 1

CAUTION!

When operated as a direct vent stove, the

flue pipe connection to the chimney has

to be gas proof and sealed with a suitable

sealing cord and heat-resistant silicone.

Ensure that all connections points at the

flue pipe connecting piece and at multip-

le section flue pipes are sealed with Hase

sealing paste (see Installation Instruc-

tions).

6.

Combustion Air Connection

The combustion air in the fire box is solely supplied

by a customer-provided supply air pipe and the Hase

Air System pipe connections. The connecting piece

for the Hase Air system is located on the back side

of the stove. The sealed pipe connections are either

routed directly to the outside or connected to a sui-

table air/flue gas system (AFS). Another option is to

provide the supply air from a room that has its own

independent outside air supply (e.g. cellar or base-

ment).

The customer-provided air inlet duct has to be con-

structed using plain, smooth pipes (steel pipes in

compliance with 24145, drain pipes in accordance

with DIN 19534 and EN 1451B) with a minimum dia-

meter of 100 mm, a maximum of two bends and a

permissible total length of 4.5 meters. Designs using

longer piping and pipes with more than two bends

have to be verified through calculations. The required

supply of combustion air has to be ensured (see Part

1 “Technical Data”). The air supply pipe has to be

equipped with suitable inspection openings for ins-

pection and cleaning purposes. The entire air supply

pipe has to be airtight. We advise discussing this

with your local planning officer. At the air inlet ope-

ning, we recommend installing an animal protection

screen with a mesh size of 10 mm.

7.

Butterfly Valve

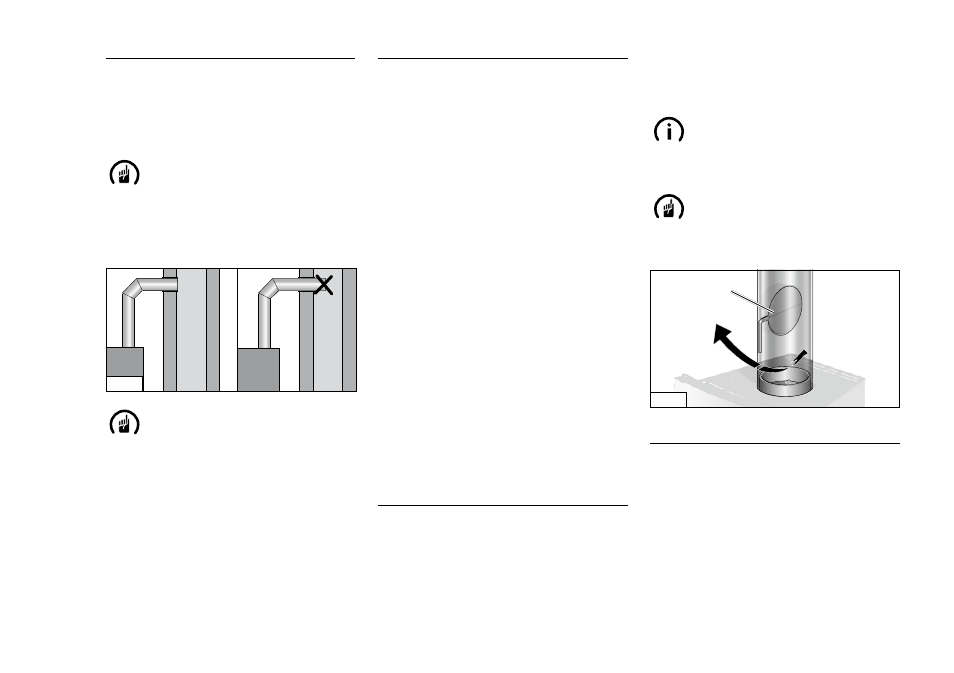

The butterfly valve (Fig. 2/a) is an optional control

element. It is fitted in the flue pipe and used to re-

gulate the flue gas flow, and can thus slow down

the burning-off process. When the handle’s posi-

tion is diagonal to the flue pipe, the flue gas flow

rate is turned to minimum. In the case of increased

pump pressure in the chimney unit, we recommend

installing a butterfly valve. Please comply with the

country-specific legal regulations.

NOTE!

Make sure the butterfly valve (Fig. 2/a) is

open before opening the fire box door duri-

ng the burning phase.

CAUTION!

With direct vent stove operation, the instal-

lation of a butterfly valve is not permitted

due to the required air tightness

a

fig. 2

8.

Regulating the Combustion Air

We develop an individual air duct routing for each

Hase stove model, to ensure that the necessary

combustion air is guided to the right areas in the fire

box.

The primary air supplies the glowing embers with

oxygen. The secondary air is heated and guided to

the flame area. It minimises the formation of soot on

the fire box windows.