13 fault finding – Glow-worm EnergySaverCombi 100 User Manual

Page 31

31

221854B

If after checking all previous points the error code is still present,

this suggests that the heat exchanger has become partially

blocked. See section 12.11 for major service of heat exchanger.

Fault Code =

2

and

8

.

The fan is stationary or there is no fan speed signal.

Check the wiring to the fan.

Check the fan and replace as necessary. See section 12.3 for

fan removal.

Fault Code =

2

and

9

.

The fan is stationary and open circuit.

Check the wiring to the fan.

Fault Code =

1

and

8

.

The heating flow thermistor is detecting a temperature in

excess of 100

°

C.

Check that the pump is functioning correctly.

Check that the system is not air locked.

Check that the flow rate through the installation is high enough.

Refer to section 4.3.

Fault Code =

1

and

9

.

The heating return thermistor is detecting an excessive

temperature.

Check that the pump is functioning correctly.

Check that the system is not air locked.

Check that the flow rate through the installation is high enough.

Refer to section 4.3.

Fault Code =

2

and

5

.

The rate of temperature rise measured by the heating flow

thermistor is too high.

Check that the pump is functioning correctly.

Check that the system is not air locked.

Check that the flow rate through the installation is high enough.

Refer to section 4.3.

13.2 Central Heating

If the central heating fails to operate, or the temperature

provided is poor, check the following:

Check that all external controls are calling for heat.

Check that the boiler controls are set correctly, see section 11.

Increase temperature or return to 'Normal mode'

,

if necessary.

If there is still a problem, check that no domestic hot water taps

are dripping. A dripping tap can prevent the boiler from

operating in the central heating mode. Repair any leaking taps

as necessary.

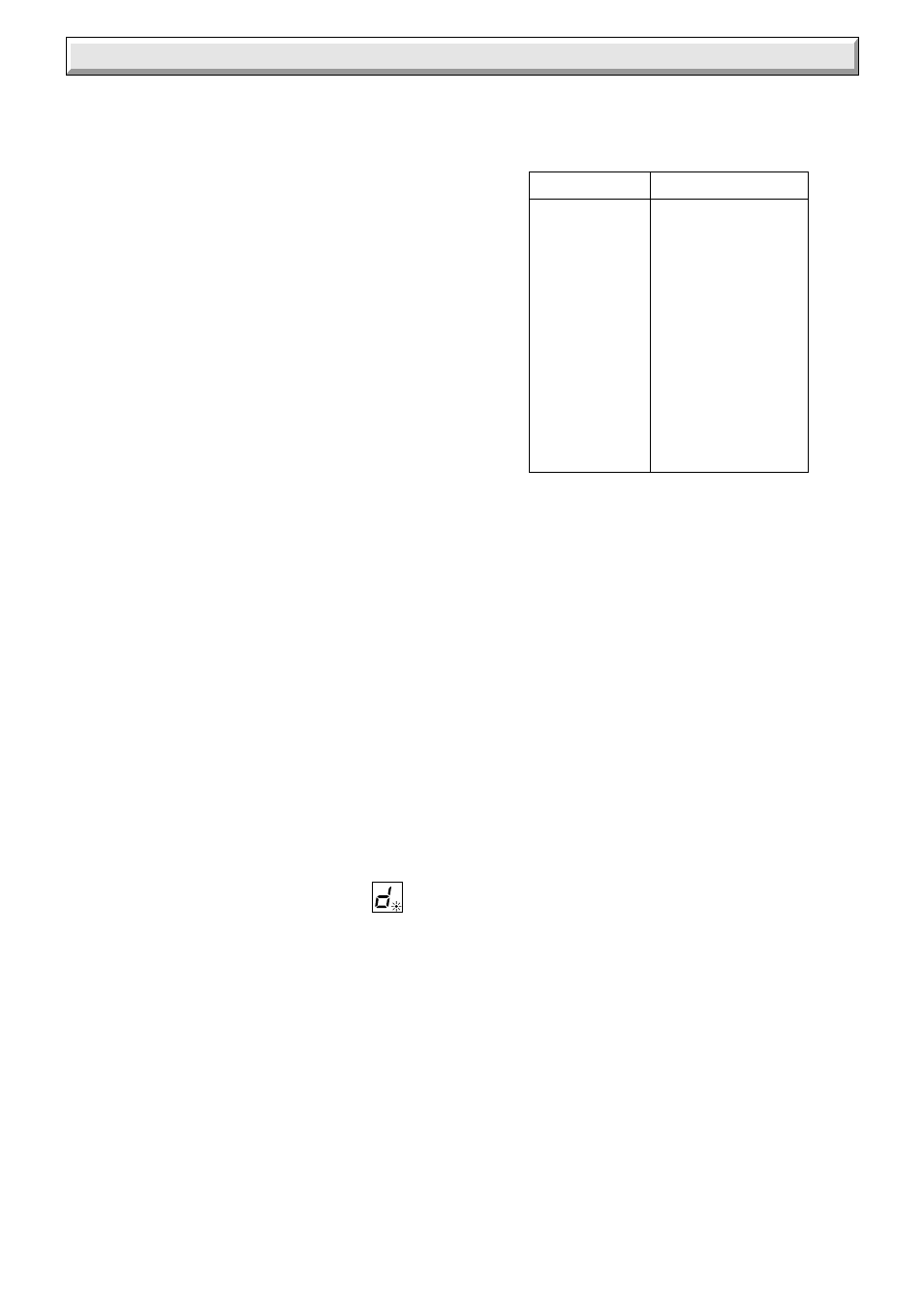

13.3 Thermistor Characteristics

All three thermistors used on the boiler can be checked for

accuracy against the chart below if their performance is suspect.

13 Fault Finding

Temperature ˚C

Resistance (Ohms)

0

35400

10

22500

20

14700

25

12000

30

9835

40

6712

50

4672

60

3311

70

2388

80

1749

90

1300

100

980

110

749

Note that there is no error message displayed for a fault

involving the Domestic Hot water thermistor.

The thermistors should be checked at both hot and cold

temperatures.

13.4 Combustion

If the combustion CO

2

measured during servicing in section

12.6 is too high and cannot be adjusted, or the CO levels

measured at full rate are unacceptable, then the following

possibilities should be investigated and cured.

A. Check the flue system has been correctly installed and that

both air and flue ducts are unobstructed internally, see section

7.5.

B. Ensure that correct terminal clearances are observed and

that product recirculation is impossible, see section 3.3.

C. Ensure that the condensate drain is not blocked. Refer to

section 12.5 for cleaning of the condensate drain and section

14.21 for removal if faulty.

D. Check the condition of the burner and clean or replace as

directed in section 12.3.

E. Check and clean the air inlet to the fan and check that the

seals are in good condition as directed in section 12.3.

F

.

If after checking all previous points the heat exchanger may

have become partially blocked, see section 12.11 for major

servicing of the heat exchanger.

13.5 Operating Procedure

Refer to sections 11.8 to 11.12 if necessary to check for correct

operation of the central heating and domestic hot water.