11 commissioning – Glow-worm EnergySaverCombi 100 User Manual

Page 24

24

221854B

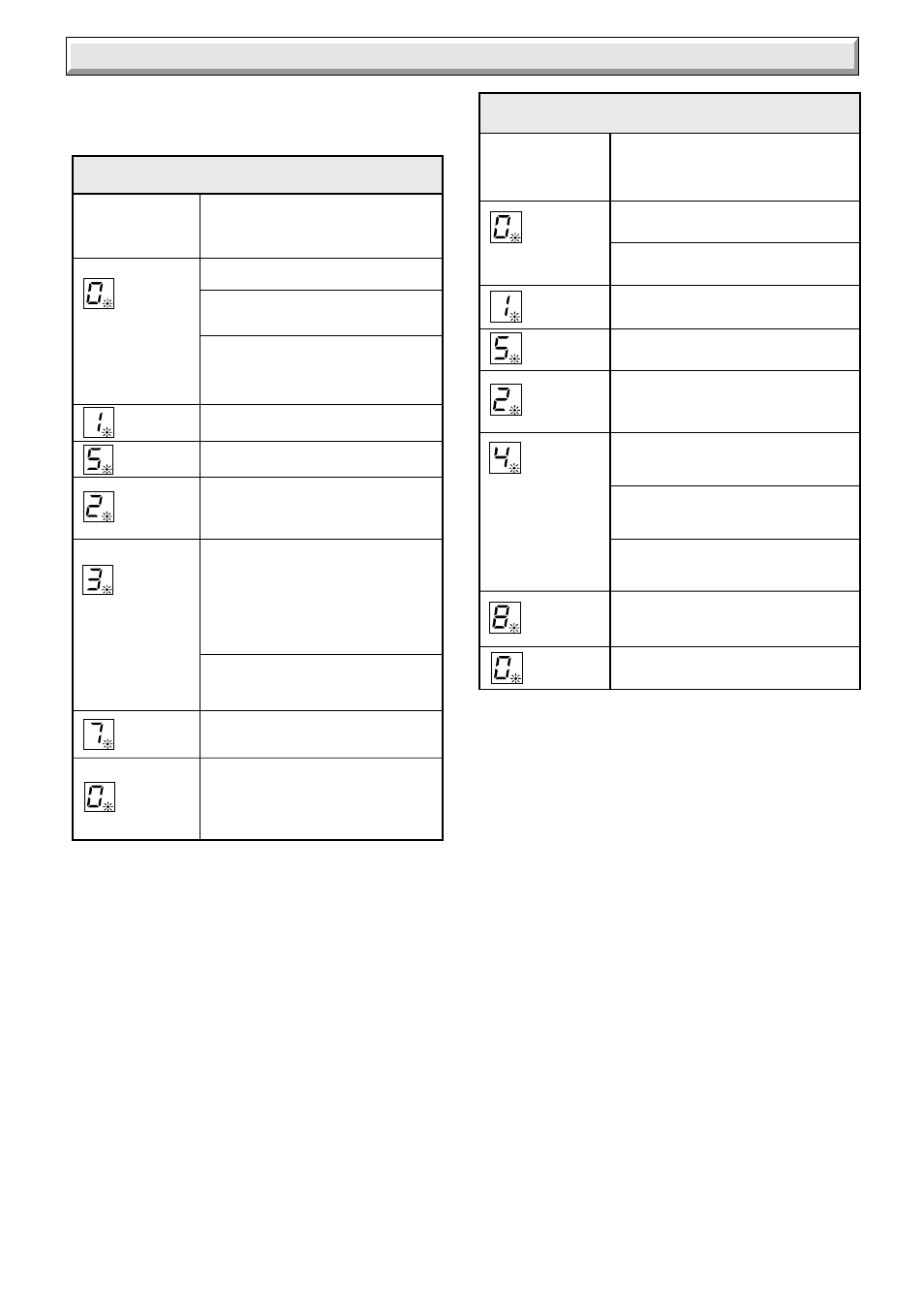

The operating sequence of the appliance during central heating

and domestic hot water production can be checked against the

following two tables.

DISPLAY

ACTION

(Operating

function)

No demand.

Create demand by turning on

a hot water tap.

Pump and fan start.

Fan running up to speed.

Gas valve opens

and ignitor sparks for 3 seconds.

Burner ignites.

Hot water supplied to thermal

store.

End of hot water demand

i.e. hot water turned off.

Burner modulates to bring thermal

store to correct temperature.

Burner shuts down and

pump overrun commences.

No demand.

DOMESTIC HOT WATER SEQUENCE TABLE

6573

11 Commissioning

DISPLAY

ACTION

(Operating

function)

No demand.

Create demand by switching on

timer or room thermostat.

Three way valve switches to

central heating

(approx. 15 seconds).

Pump and fan start.

Fan running up to speed.

Gas valve opens

and ignitor sparks for 3 seconds.

Burner ignites.

Burner runs at ignition rate (70%)

for 10 seconds.

Rate drops to minimum for

60 seconds.

Input adjusts according to heating

option selected.

End of heating demand

i.e. room thermostat satisfied.

Burner shuts down and timed

pump overrun commences.

No demand.

3 way valve switches back

to domestic position

(approx 15 seconds).

CENTRAL HEATING SEQUENCE TABLE

6572

11.13 Pump Exercise Program

After a power cut or every 24 hour in holiday mode the three way

valve will switch and the pump will run for one minute to prevent

the components from sticking. This will also occur during

normal operating if there is no domestic or central heating

demand for more than 24 hours.

11.14 Frost Protection

During periods of no demand the boiler is protected by a frost

protection procedure. If the heating outlet temperature falls to

7

°

C the pump will start. If the heating outlet temperature

continues to fall to 3

°

C the burner is ignited. The burner is

extinguished when the heating outlet reaches 10

°

C, the pump

will run for a further 15 minutes. This function primarily protects

only the boiler.

If an additional frost thermostat is fitted, switching of this will

operate the boiler.

11.15 Instruct the User

Instruct and demonstrate the lighting procedure and advise the

user on the safe and efficient operation of the boiler.

Instruct on and demonstrate the operation of any heating

system controls.

Advise the user on the use and maintenance of any scale

reducer and pass on any relevant instructional documents.

Advise that to ensure the continued efficient and safe operation

of the boiler it is recommended that it is checked and serviced

at regular intervals. The frequency of servicing will depend upon

the installation conditions and usage, but in general, once a

year should be enough.

Draw attention, if applicable, to the current issue of the Gas

Safety (Installation and Use) Regulations, Section 35, which

imposes a duty of care on all persons who let out any property

containing a gas appliance.

It is the Law that any servicing is carried out by a competent

person.

Advise the user that, like all condensing boilers this appliance

will produce a plume of condensation from the flue terminal in

cool weather. This is due to the high efficiency and hence low

flue gas temperature of the boiler.

Advise the user of the precautions necessary to prevent damage

to the system, boiler and the building, in the event of the heating

system being out of use during frost or freezing conditions.

Advise the user that the permanent mains electrical supply

SHOULD NOT be switched off, as the built in frost protection

and pump/valve saver program would not be operable.

Reminder, leave these instructions and the ‘Benchmark’ logbook

with the user.