6 control & pressure checks – Glow-worm Miami 4 User Manual

Page 13

13

221904D

6 Control & Pressure Checks

GAS TAP

PRESSURE

TEST POINT

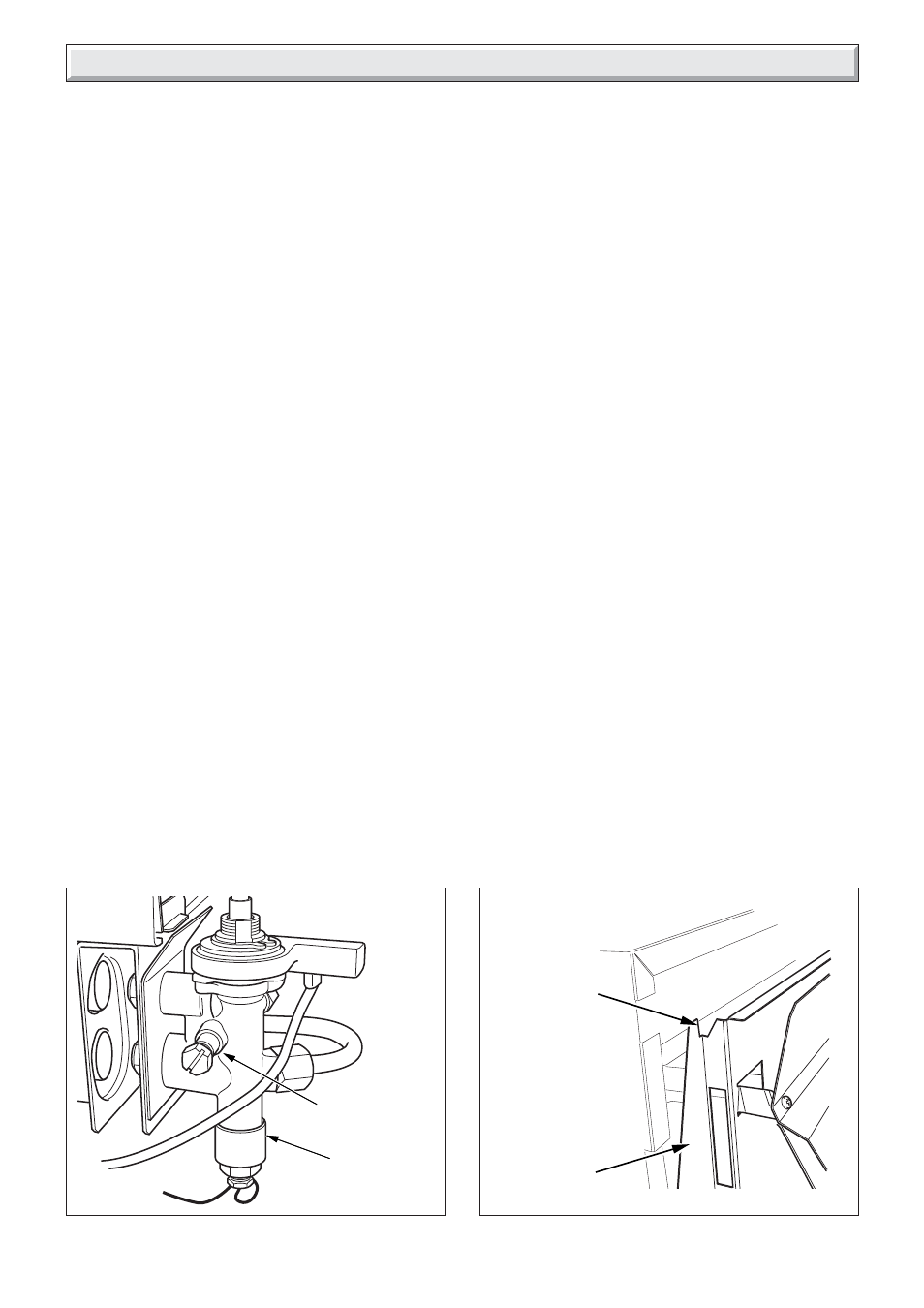

Diagram 6.1

9477

6.1 Check Control Settings

If closed, open the fire isolating valve.

To check the control positions temporarily place the case

loosely over the chassis. Fit the control knob over the gas tap

spindle.

Depress the control knob and turn anticlockwise partially towards

the 1/IGN position until some resistance is felt. Keep depressed

at this position for a few seconds to purge air from the system

then, while keeping it depressed, turn fully to the 1/IGN position,

two audible clicks will be heard. A spark should be generated at

the pilot while turning. The spark should ignite the pilot.

When pilot ignition has been achieved, keep the control knob

depressed for approximately ten seconds to allow the

thermocouple probe to warm up and then release it. If the pilot

does not remain alight, ensure that the air has been purged, that

the pilot orifice is clear and that the thermocouple connections

are sound. Replace the pilot unit if necessary (see servicing

section of this manual).

Check all the control settings. These are:

Knob

Radiants Condition

Position

2

Centre radiant on low. Outer radiants off.

3

Centre radiant fully on. Outer radiants off.

4

Centre radiant fully on. Outer radiants on low.

5

All radiants fully on.

6.2 Flame Supervision Device

The pilot unit incorporates a system which will automatically

shut off the gas supply if the pilot flame goes out or if there is

insufficient oxygen due to spillage or lack of ventilation.

Check that the system operates properly as follows;

Light the appliance. Set at position 5 and leave for one minute.

Turn back to “OFF” to extinguish the pilot. Note the time when

the pilot goes out. Listen for a snap sound at the gas tap. Note

the time when the sound is heard. This sound is caused by an

electromagnetic valve shutting off the gas supply through the

tap. The valve is located in the body of the tap. The valve should

operate within 60 seconds of the pilot going out. If the valve does

not operate within this time limit do not allow the appliance to be

used until the fault has been corrected.

6.3 Flue Blockage Safety Device

This monitoring system must not be adjusted, bypassed or put

out of operation.

This monitoring system, or any of its parts, must only be

exchanged using Glow-worm authorised parts.

6.4 Check Reference Pressure

The appliance is pre-set to give the correct heat input at the inlet

pressure shown in section 1 of this manual. No adjustment is

necessary.

Detach the control knob from the spindle. Remove the case.

Check the burner pressure by fitting a pressure gauge at the test

point. The test point is on the gas tap, see diagram 6.1. Check

the pressure with the appliance alight and set at maximum

output (Control position 5).

After checking, turn off the appliance. Remove the pressure

gauge and replace the test point sealing screw. Relight the

appliance. Turn to the maximum output position and test around

the sealing screw for gas soundness with a suitable leak

detection fluid.

If all the above checks are satisfactory, continue with the

installation. If not, check the control and ignition circuitry and

components as described in the servicing section of this manual.

6.5 Case Fitting

Remove the protective wood transit strips (secured with panel

pins) from the bottom of the wooden case sides.

Place the case over the chassis. Make sure that the channel

near the top of the rear of the outer case locates fully into the

wings of the chassis back panel, see diagram 6.2.

Fit the control knob firmly on to the control spindle.

Refit the two case retaining screws at the front of the case near

the bottom corners.

Diagram 6.2

9476

BACK PANEL

WING (2)

CHASSIS

BACK PANEL