Table 1 : relay failsafe settings, Table 2: sensor output, 4 installation verification – ENMET GSM-60 User Manual

Page 11

GSM-60

ENMET Corporation

8

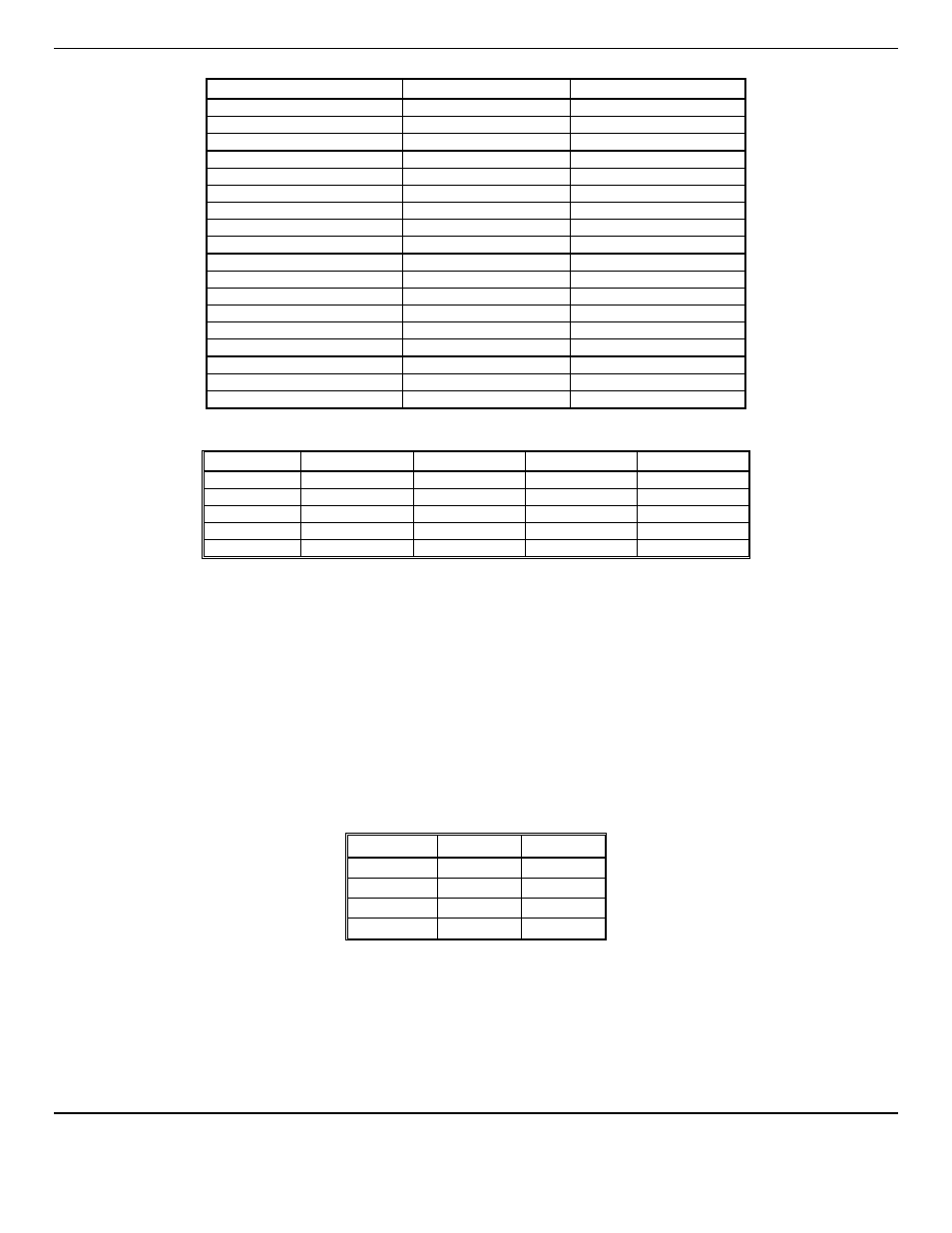

Table 1 : Relay Failsafe Settings

Position

Failsafe-Alarm

Non-Failsafe-Alarm

J5

Relay 1 - NO

Normally Open

Normally Closed

J5

Relay 1 - COM

Common

Common

J5

Relay 1 - NC

Normally Closed

Normally Open

J6

Relay 2 - NO

Normally Open

Normally Closed

J6

Relay 2 - COM

Common

Common

J6

Relay 2 - NC

Normally Closed

Normally Open

J8

Relay 3 - NO

Normally Open

Normally Closed

J8

Relay 3 - COM

Common

Common

J8

Relay 3 - NC

Normally Closed

Normally Open

J10

Relay 4 - NO

Normally Open

Normally Closed

J10

Relay 4 - COM

Common

Common

J10

Relay 4 - NC

Normally Closed

Normally Open

J14

Relay 5 - NO

Normally Open

Normally Closed

J14

Relay 5 - COM

Common

Common

J14

Relay 5 - NC

Normally Closed

Normally Open

J15

Relay 6/FLT - NO

Normally Open

N/A

J15

Relay 6/FLT - COM

Common

N/A

J15

Relay 6/FLT - NC

Normally Closed

N/A

Relays can be linked to specific alarms. The table below shows the default relay links. They may be changed in the

maintenance menu if required. See Section 5.0.

Channel 1

Channel 2

Channel 3

Channel 4

Relay 1

Low Alarm

Relay 2

Low Alarm

Relay 3

Low Alarm

Relay 4

Low Alarm

Relay 5

High Alarm

High Alarm

High Alarm

High Alarm

In addition, there is a fault relay, which changes state whenever the instrument is in a fault condition. The contact positions are

noted on the circuit board next to each terminal. See Figure 2A. The coil of this relay is energized when the instrument is in

the non-fault state; the contact conditions given on the circuit board next to the terminal, are for the non-energized state, which

is identical to the fault state.

These relay contacts can be used to operate auxiliary alarms or other functions. It is recommended that power for auxiliary

equipment be supplied from an independent power source, separate from the

GSM-60

. Place a hole in the enclosure for a wire

exit, and use appropriate cable fittings. Be sure to note the location and depth of hardware inside the enclosure.

3.3.3 Optional 4-20mA Outputs

Isolated 4-20 mA outputs are available for data logging or other purposes. An output is supplied for each sensor supplied in a

particular instrument, and can be added when a sensor is added in the field. These outputs are available on the Connector 1 for

channels 1 & 2 and Connector 2 for channels 3 & 4.

4mA corresponds to a sensor reading at the bottom of the instrument range and 20mA corresponds to a full scale reading.

Standard ranges are shown in Table 2.

Table 2: Sensor Output

Sensor

4mA

20mA

CO

0

50

O2

0

30

CO2

0

5000

HC

0

100

Wiring requirements are the same as for the relays.

3.4 Installation Verification

All instruments are calibrated at the factory. You may, if a calibration kit is available, calibrate the any and all gas channels of

the instrument 24 hours after installation to verify proper installation and instrument operation. See Section 5.0, Maintenance,

for calibration instructions. Calibration is also recommended after the first month of operation. Subsequent calibrations should

be performed every 3 months. The dew point sensor can not be calibrated in the field.