Recommended wire gauge – ENMET GSM-60 User Manual

Page 10

GSM-60

ENMET Corporation

7

3.3.1 Sensor/Transmitter Connection

Sensor/Transmitters are connected to the

GSM-60

control unit with two or three-conductor wiring, use the correct oiltight

fitting. Size of wire depends on the distance between the sensor/transmitter and the control unit.

See Recommended Wire Gauge Table below.

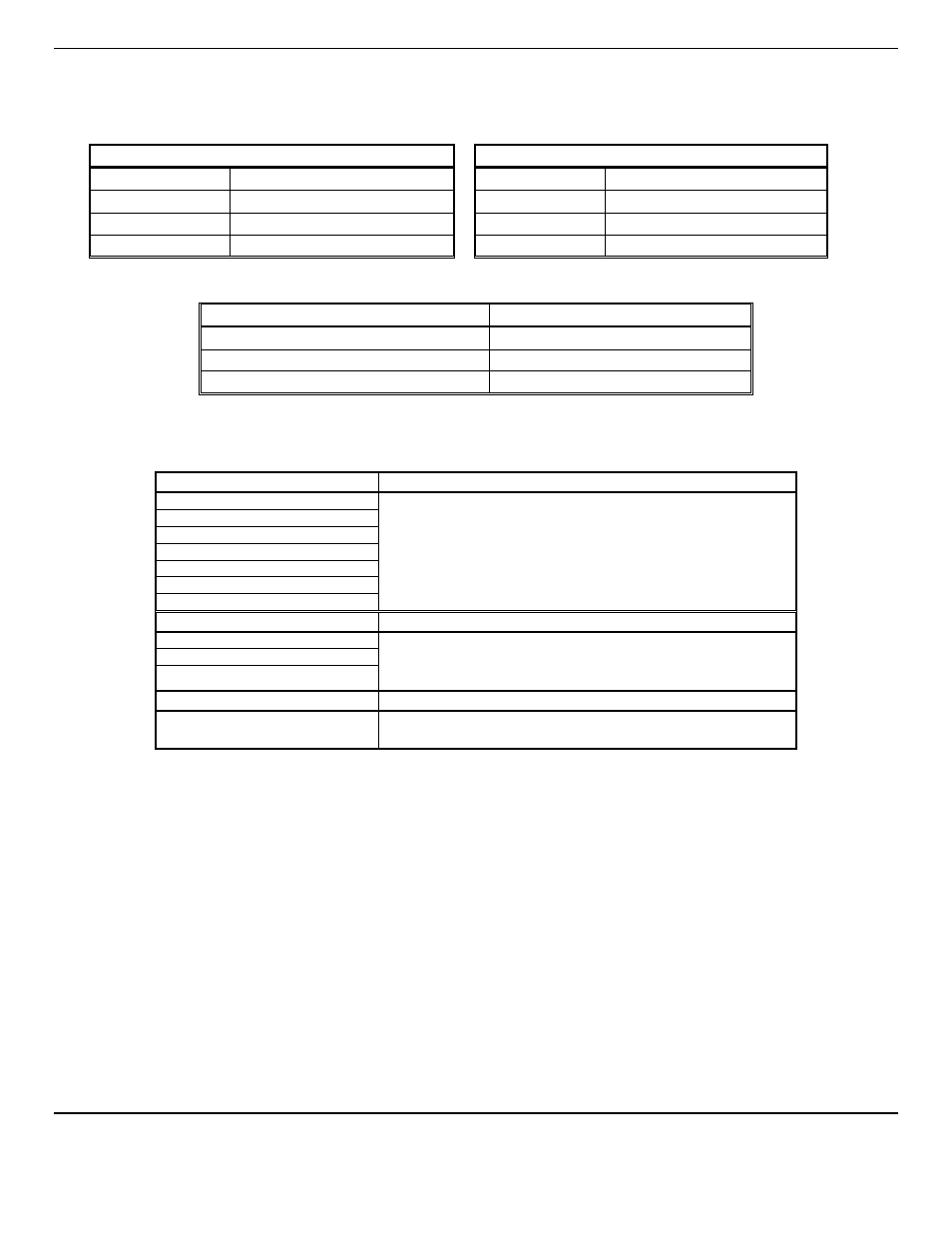

2 Wire for Sensors/Transmitter

3 Wire for Sensors/Transmitter

Position

Function

Position

Function

1

Power +24

V

DC

1

Power +24

V

DC

2

Not Used

2

Power Ground

3

Signal/Return to Ground

3

Signal

Recommended Wire Gauge

Distance from Sensor to Control Unit

Recommended Wire Gauge

< 500 feet

16 AWG

501 – 800 feet

14 AWG

Longer Distances

Contact Factory

N

OTE

: Sensor Location

Gases have different densities. Some are heavier than air and concentrate at the bottom of a space. Some are lighter than air

and gather at the top. Consider the density of the gas you want the sensor to detect when you install the sensor. Some

examples are given below.

Heavier than Air Gas

Sensor Location

Bottled LP (liquefied petroleum)

Interior wall; 18-24" from floor.

•

D

O

N

OT

locate directly above or beside gas appliances (ovens,

heaters).

•

Avoid locating anywhere near a vent or window or near an outside

doorway.

Propane

Butane

Gasoline

Trichloroethylene

Vaporized hydrocarbons

Hydrogen sulfide

Lighter than Air Gas

Sensor Location

Natural gas (methane)

Near ceiling.

•

D

O

N

OT

locate directly above appliances where it is subject to direct

exposure to heat or steam.

Ammonia

Hydrogen

Same Density as Air Gas

Sensor Location

Carbon Monoxide

4-6 feet above the (generally uniform) floor.

•

D

O

N

OT

locate in direct air currents of windows, doors, or vents.

If you have a question involving the location of a unit or sensor, please contact your distributor or

ENMET

personnel. A

technician will analyze the question and recommend a location.

3.3.2 Relay Contacts

Relay contacts are available for each alarm; these are

SPDT

, rated at 10Amp at 110

V

AC

, and may be latching or non-latching

as required by the application.

They are accessed on the terminals next to each relay see Figure 2 & 2A. The contact positions are noted on the circuit board

next to each terminal.

Relays may also be configured as failsafe or non-failsafe. The default alarm relay configuration is for latching mode, and

failsafe. They may be reconfigured in the maintenance menu. See section 5.3.5 & 5.3.6

The PC Board is labeled for the relays in their un-energized state. If the relay is configured for failsafe, then this is also the alarm

condition state. Non-failsafe configured relays in the alarm state, are the reverse of the PC board labeling. Note that the

Fault(FLT) relay cannot be set to operate in a Non-Failsafe mode. Please see the Table 1: