Soldering – Elenco Soldering Station User Manual

Page 5

-4-

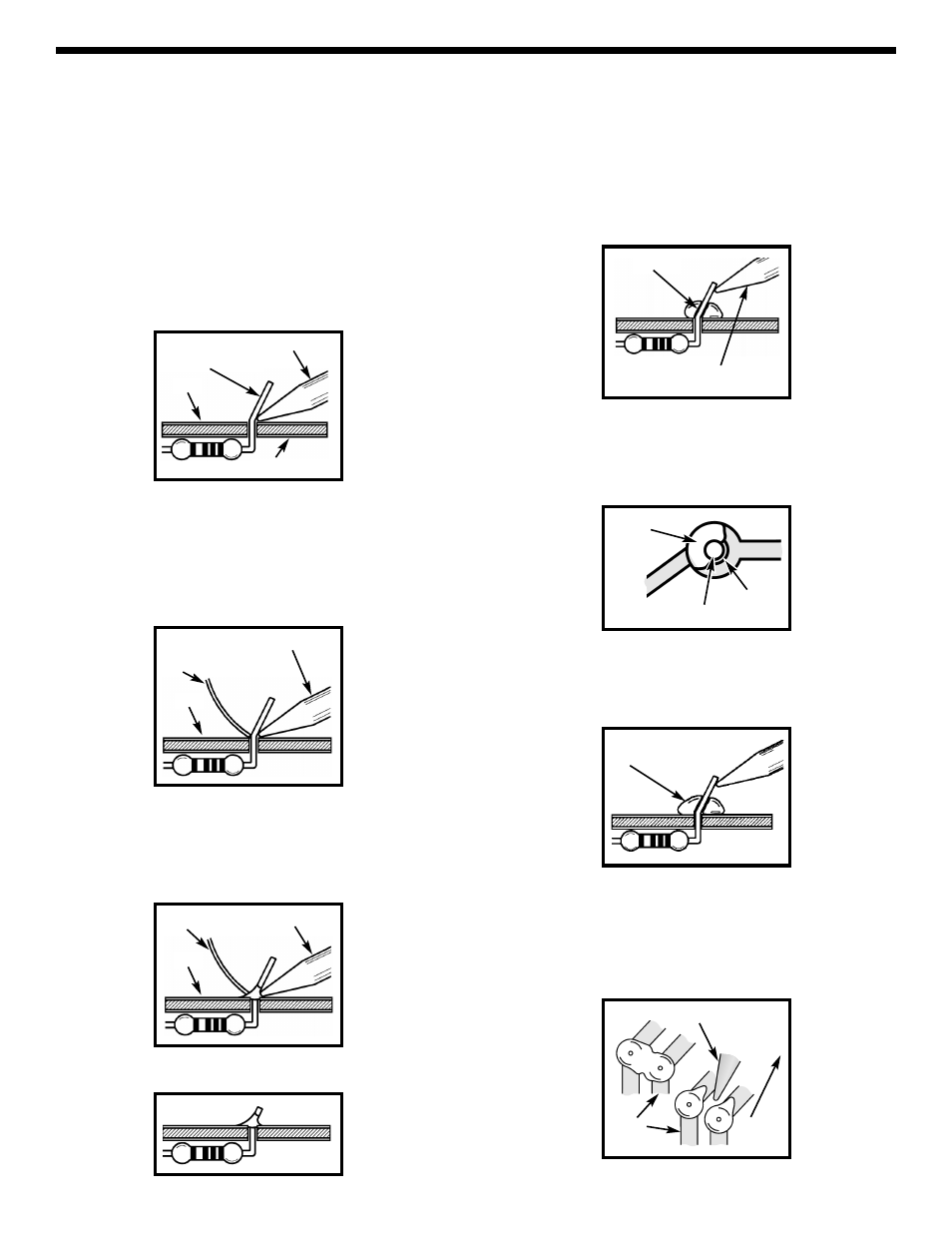

What Good Soldering Looks Like

A good solder connection should be bright, shiny,

smooth, and uniformly flowed over all surfaces.

Soldering a PC board

1. Solder all components from the copper foil side

only. Push the soldering iron tip against both the

lead and the circuit board foil.

2. Apply a small amount of solder to the iron tip.

This allows the heat to leave the iron and onto

the foil. Immediately apply solder to the

opposite side of the connection, away from the

iron. Allow the heated component and the

circuit foil to melt the solder.

3. Allow the solder to flow around the connection.

Then, remove the solder and the iron and let the

connection cool. The solder should have flowed

smoothly and not lump around the wire lead.

4. Here is what a good solder connection looks like.

Types of Poor Soldering Connections

1. Insufficient heat - the solder will not flow onto

the lead as shown.

2. Insufficient solder - let the solder flow over the

connection until it is covered. Use just enough

solder to cover the connection.

3. Excessive solder - could make connections

that you did not intend to between adjacent foil

areas or terminals.

4. Solder bridges - occur when solder runs

between circuit paths and creates a short circuit.

This is usually caused by using too much solder.

To correct this, simply drag your soldering iron

across the solder bridge as shown.

SOLDERING

A poorly soldered joint can greatly affect small current flow in circuits and can cause equipment failure. You can

damage a PC board or a component with too much heat or cause a cold solder joint with insufficient heat.

Sloppy soldering can cause bridges between two adjacent foils preventing the circuit from functioning.

Solder

Soldering Iron

Foil

Solder

Soldering Iron

Foil

Component Lead

Soldering Iron

Circuit Board

Foil

Rosin

Soldering iron positioned

incorrectly.

Solder

Gap

Component Lead

Solder

Soldering Iron

Drag

Foil