DuraVent DuraTech 5-8 User Manual

Page 9

9

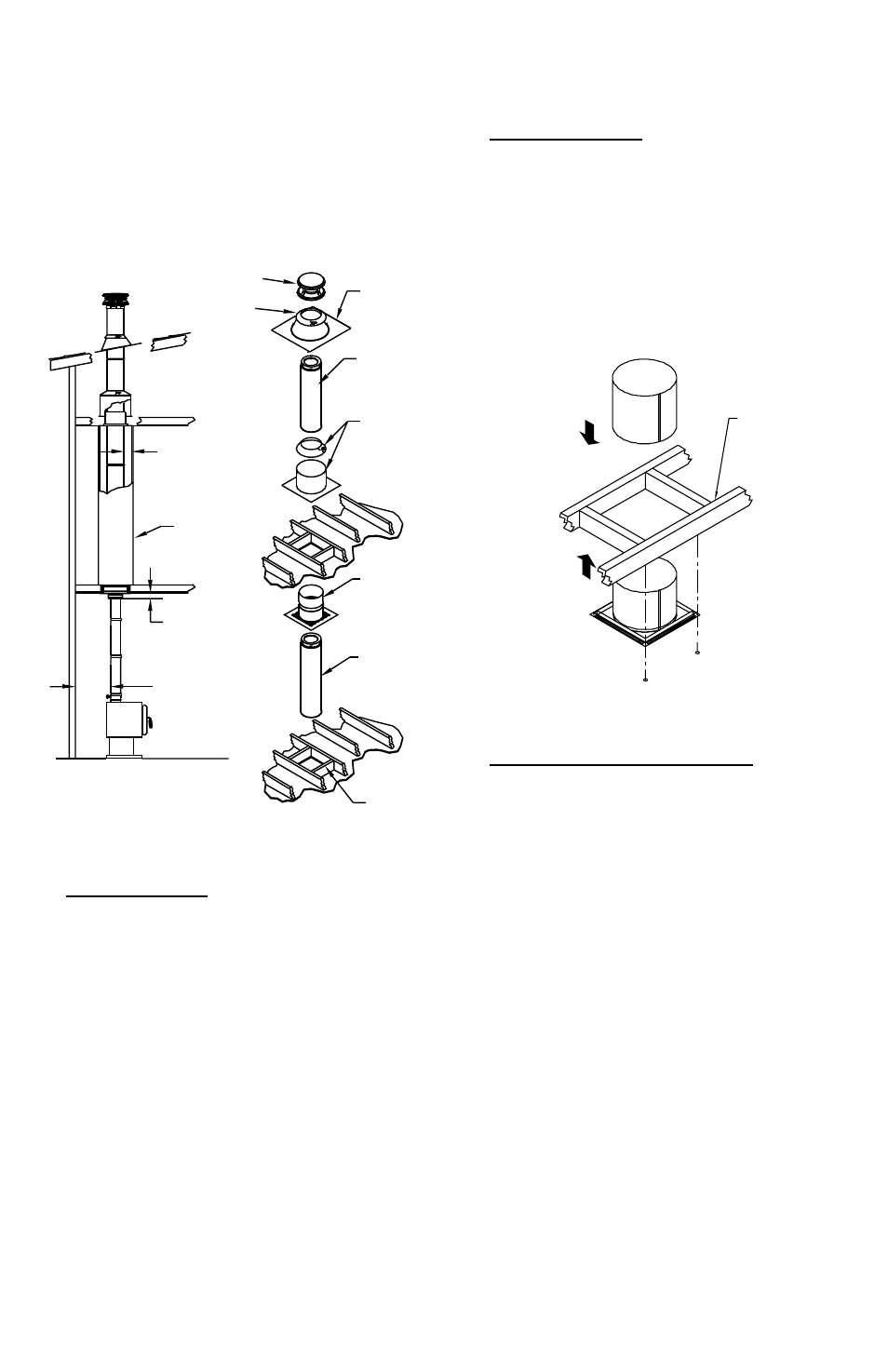

Figure 10

CAP

ADJUSTABLE

FLASHING

CHIMNEY

SECTION

ATTIC

INSULATION

SHIELD

STORM

COLLAR

FIRESTOP

RADIATION

SHIELD

CHIMNEY

SECTION

FRAMED

ENCLOSURE

2 INCH MIN

CLEARANCE

TO INSIDE OF

ENCLOSURE

REF FIG. 7

18 INCH MIN FOR

SINGLE WALL

STOVEPIPE

Figure 11

FRAMING

FIRESTOP

RADIATION SHIELD

5. Cut Roof Opening: Cut an opening in the

roof directly above the opening below, and

at least 4” larger than the chimney’s outside

diameter to provide at least a 2” clearance all

around the chimney. The chimney must be

centered within this opening and maintain the

2” clearance to combustibles.

the overlapping “U-shaped” Trim pieces so

they cover the Support Box, and secure them

to the framing members using the (6) 1-1/4”

round head wood screws provided (Fig.9).

4. Frame Openings: Frame openings in

each ceiling or floor above the Support Box

(Fig.10). These openings are to hold the

Firestop Radiation Shield and Attic Insulation

Shield. Locate each opening by dropping a

plumb bob to the four corners of the opening

below. Maintain the framing dimensions as

specified in Table 1. Warning: other than the

framing for the Reduced Clearance Support

Box, any combustible materials around

the chimney must meet the minimum 2”

clearance requirement. If Elbows must be

used to avoid an obstruction, refer to the Offset

Elbow Installation section.

6. Install Firestop Radiation Shield: A Firestop

Radiation Shield is required in multistory

installations at each floor penetration above

that where the Support Box is located.

Example: in a multistory home where the

appliance is on the ground floor (Support

Box is in the 1st floor ceiling), you would

need a Firestop Radiation Shield at the 2nd

floor ceiling, and at the 3rd floor ceiling, etc.,

including where the chimney penetrates

into the attic. Fig.10 shows a typical 2-story

installation with an attic. Note: a Firestop

Radiation Shield is not installed where the

chimney penetrates through the roof. The

Firestop Radiation Shield is installed on the

underside of the ceiling/floor framing, with the

cylindrical “tube” portion of the shield pointing

upward. (Fig.11). Use a minimum of either

(1) 8 penny nail or (1) #8, 1-1/2” wood screws

FRAMING

UNOCCUPIED

SPACE