Dunkirk Helix VLT Vertical Laser Tube, Wall Hung Modulating Condensing Boiler User Manual

Page 39

39

Gas

CO

2

CO

Min.

Max.

Natural Gas

9.0

9.5

<200ppm

Propane

10.0

11.0

<200ppm

NOTICE

Contact Technical Support for additional

information or assistance.

Natural Gas only**

1.

Measure input. Compare to table above. Continue

to measure input and CO

2

until both measured

values are within range specified in tables

.

Propane Gas

Most propane systems do not have flow meters.

1.

Check CO

2

. Propane should be between 10% and

11.0%.

• If CO

2

is low increase gas flow following figure

9-3 & 9-4.

• If CO

2

is high decrease gas flow following figure 9-3

& 9-4.

FIGURE 9-3 Gas Valve - Models

050/075/100/150/200 MBH

• To increase gas flow turn 'throttle' left or counter

clockwise

.

• To decrease gas flow turn 'throttle' right or

clockwise .

• Limit adjustment to one turn and retest.

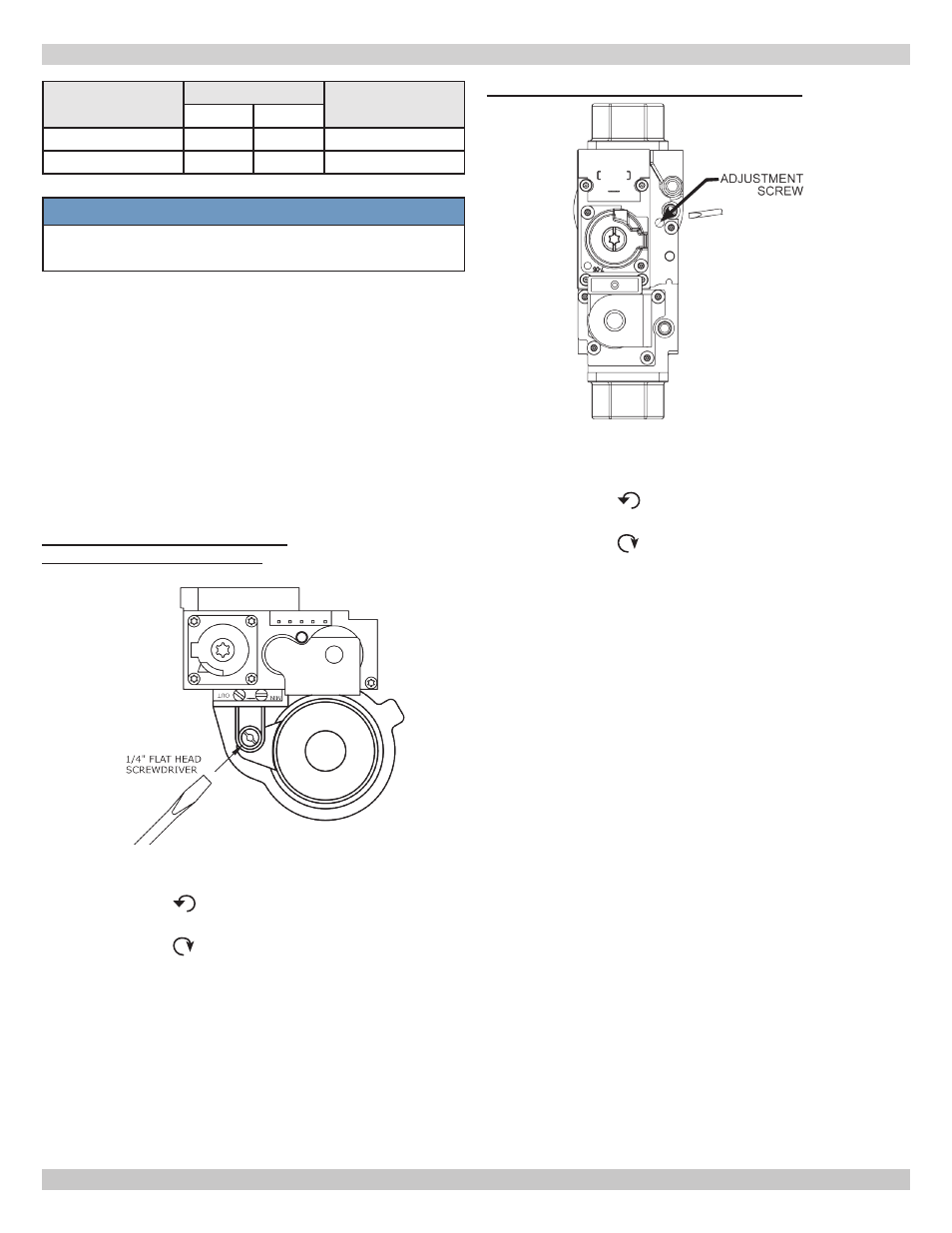

FIGURE 9-4 Gas Valve - Model 299 MBH

• To increase gas flow turn 'throttle' left or counter

clockwise

.

• To decrease gas flow turn 'throttle' right or

clockwise .

• Limit adjustment to one turn and retest.

Verify Burner, Proper Operation

1.

Inspect burner flame through Sight Glass. See

figure 11-1 & 11-2.

2.

Operate boiler through several heating cycles,

including domestic hot water, if used. Verify proper

operation.

9 - START UP PROCEDURE