Troubleshooting and helpful hints – Dillon Precision RL 550 Casefeed User Manual

Page 11

11

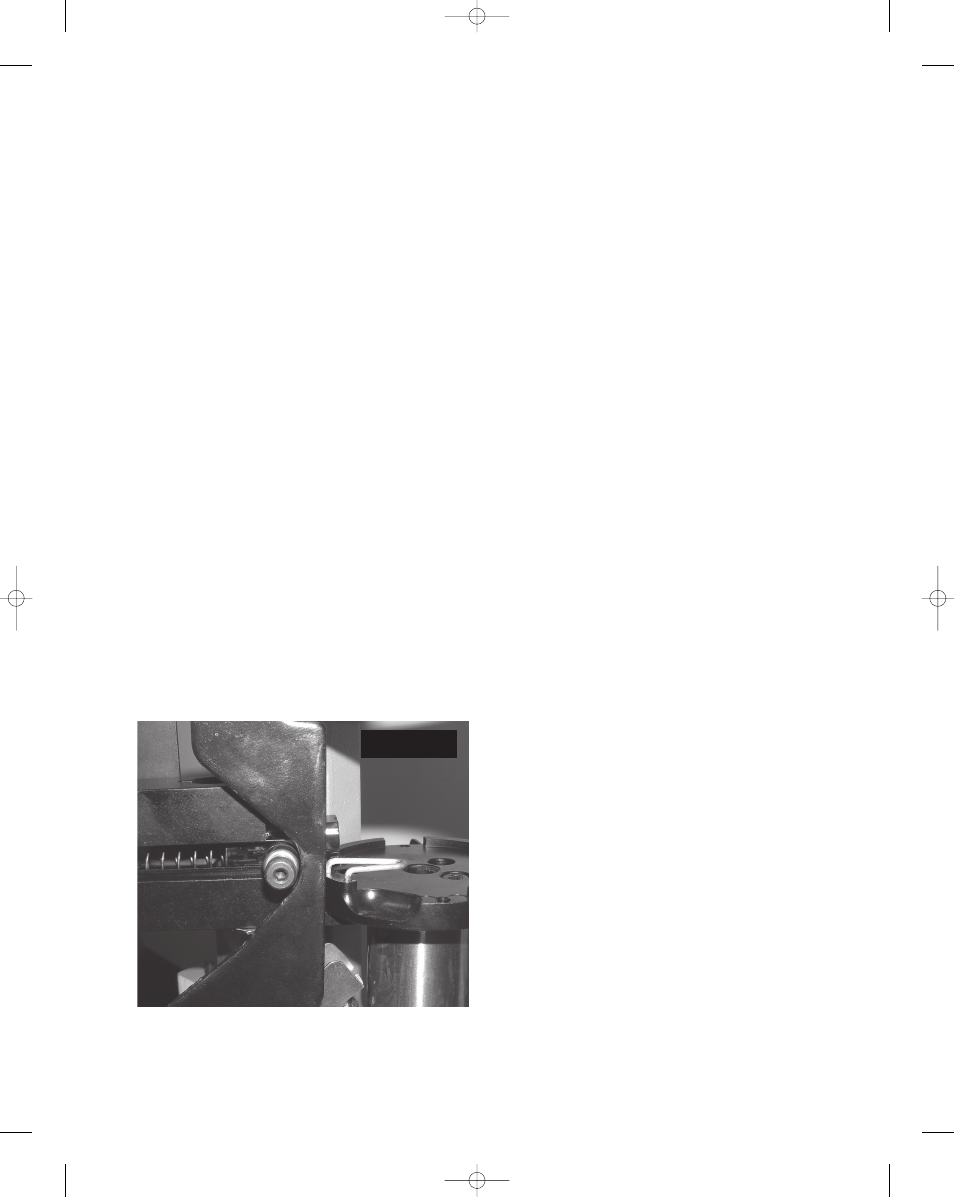

• Fine Adjustment of Cam: If you are

experiencing a problem with the case not

feeding all of the way into the shellplate

(and/or sizing die) or bouncing back out of

the shellplate, you will need to fine adjust

the cam for each and every caliber that you

are loading. You will want to start with a

case from the caliber you are preparing to

load in the first station of the shellplate. In

the following procedure you will practically

repeat the steps for setting up the cam on

initial installation with the exception of

letting the plunger rest on the case in the

shellplate instead of the housing. Pull the

operating handle down until roller on

casefeed plunger reaches about the center of

the flat on the cam and the plunger is resting

on the case in the shellplate. Loosen the

cam and slide it in or out until it is just

barely touching the roller, then re-tighten the

mounting bolts on the cam, be sure not to

release the handle until tightened. Once you

have finished loading the caliber that you

have fine-tuned the cam for, you will want to

return it to its original position by repeating

the setup steps in Note 9 [F

IGURE

20].

• If you are having trouble with the case

sliding through or sticking in the Station 1

locator make sure there are no burrs on the

inside edges of the tracks or that they have

not been bent or crushed.

• If you are experiencing a sticky action

with the plunger you may have tumbling

media or other debris that is causing the

plunger to stick or bind. You will have to

remove the shellplate, shellplate bolt,

indexing star and the Station 1 locator so

you can remove the plunger from the

casefeed body. To remove the plunger it

will be easier to pull the operating handle

down so the roller is on flat in the center of

the cam to reduce spring tension. Slowly

remove the shoulder bolt and two

bearings. The spring will want to push the

plunger out of the body, once the bolt is

out remove the plunger and spring from

the body. Use a clean rag to wipe off the

plunger and the inside of the housing. Re-

lube the plunger and housing with MIL-

COMM TW-25B (part #15732) grease or

equivalent. You can also re-lube the

bearing assembly at this time. Re-insert

spring into plunger and slide assembly into

housing making sure spring is held down

by the pin at end of housing. Install

bearing assembly and tighten. At this time

also lube the channel that the bearing rides

in on the housing with the same grease.

• If you have double feed, it will be easiest

to clear out the lower feed tube and

remove the casefeed adaptor so you can

pull the plunger all the way back and

remove the cases.

• If you are having trouble with the case

lining up or jamming in the sizing die

mouth, make sure you are using a sizing

die with a radiused entry on the mouth. We

recommend that a Dillon Sizing Die be

used – Dillon dies have radiused mouths

that allow the case to enter the die easier.

• If you need further assistance please call:

1-800-223-4570

Troubleshooting and Helpful Hints

F

IGURE

20

550 Casefeed Manual, May 2007 5/22/07 8:30 AM Page 11