Linear & rotary cylinder load vs. velocity – Bimba SPCS User Manual

Page 10

2014.01.23 rev4

10

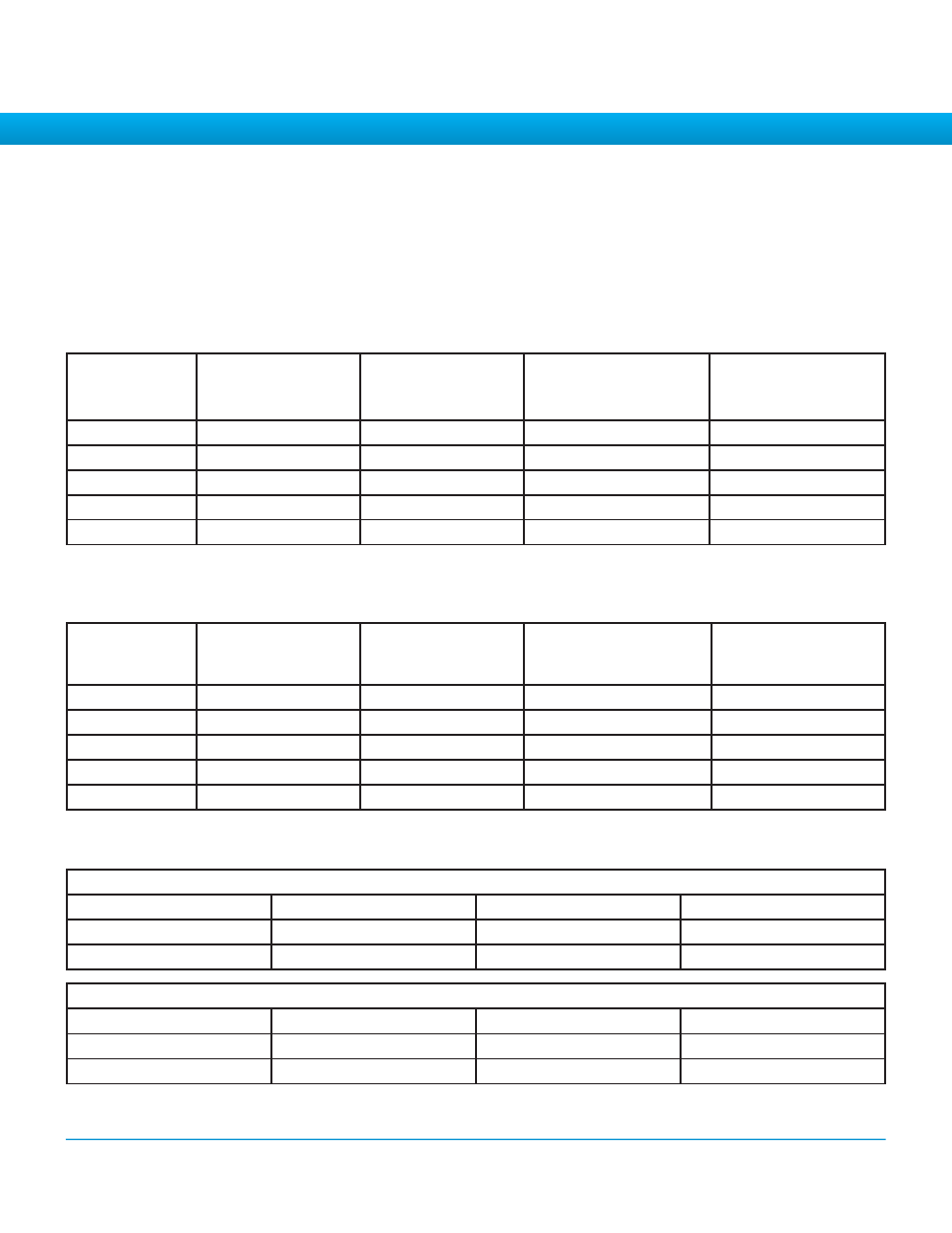

3. Linear & Rotary Cylinder Load Vs. Velocity

Maximum Moving Mass

Bore Size

Average Velocity

Without Overshoot @

Max Payload [in/sec]

Maximum Payload

[lbs.]

Average Velocity @ 50%

Max Payload

[in/sec]

Average Velocity @ 25%

Max Payload [in/sec]

09

20

50

20

30

17

10

100

20

30

31

15

200

20

30

50

15

315

25

30

70

15

450

20

20

Linear Cylinder

Vertical Applications

Bore Size

Average Velocity

Without Overshoot @

Max Payload [in/sec]

Maximum Payload

[lbs.]

Average Velocity @ 50%

Max Payload

[in/sec]

Average Velocity @ 25%

Max Payload [in/sec]

09

70

5

100

100

17

70

10

60

60

31

50

30

40

60

50

15

95

30

30

70

20

135

20

20

Rotary Actuator

Rack and Pinion - Single Rack

Bore Size

Rotation

Average Velocity

Max Torque

1-1/2”

0 to 360°

150° per second

30 in/lb.

2”

0 to 360°

150° per second

84 in/lb.

Rack and Pinion - Double Rack

Bore Size

Rotation

Average Velocity

Max Torque

1-1/2”

0 to 360°

150° per second

60 in/lb.

2”

0 to 360°

150° per second

144 in/lb.

T

he tables below recommend the maximum moving mass controlled by a SPCS-2 for horizontal and

vertical applications. Information for Bimba’s PFC, Pneu Turn and Ultran magnetically coupled cylinders is

included. Actual mass will vary based on cylinder speed and mechanical assembly

(e.g. friction in cylinder or system, air pressure, etc.)

Linear Cylinder

Horizontal Applications