Set up and adjustments – Bimba PCS Rod Lock User Manual

Page 4

Set up and adjustments

Set the deadband (page 15) The deadband adjustment changes the tolerance on the ending

position of the PFC rod. Smaller deadbands mean a tight tolerance and higher

position of the PFC rod. Smaller deadbands mean a tight tolerance and higher

positioning accuracy. Higher deadbands are required for greater loads.

1.

Application sizing chart (PCS manual page 23, below) identifies “Zero Friction Deadband

Voltage” for setting deadband. The deadband setting can be varied from 0.005 to 0.500 VDC.

2.

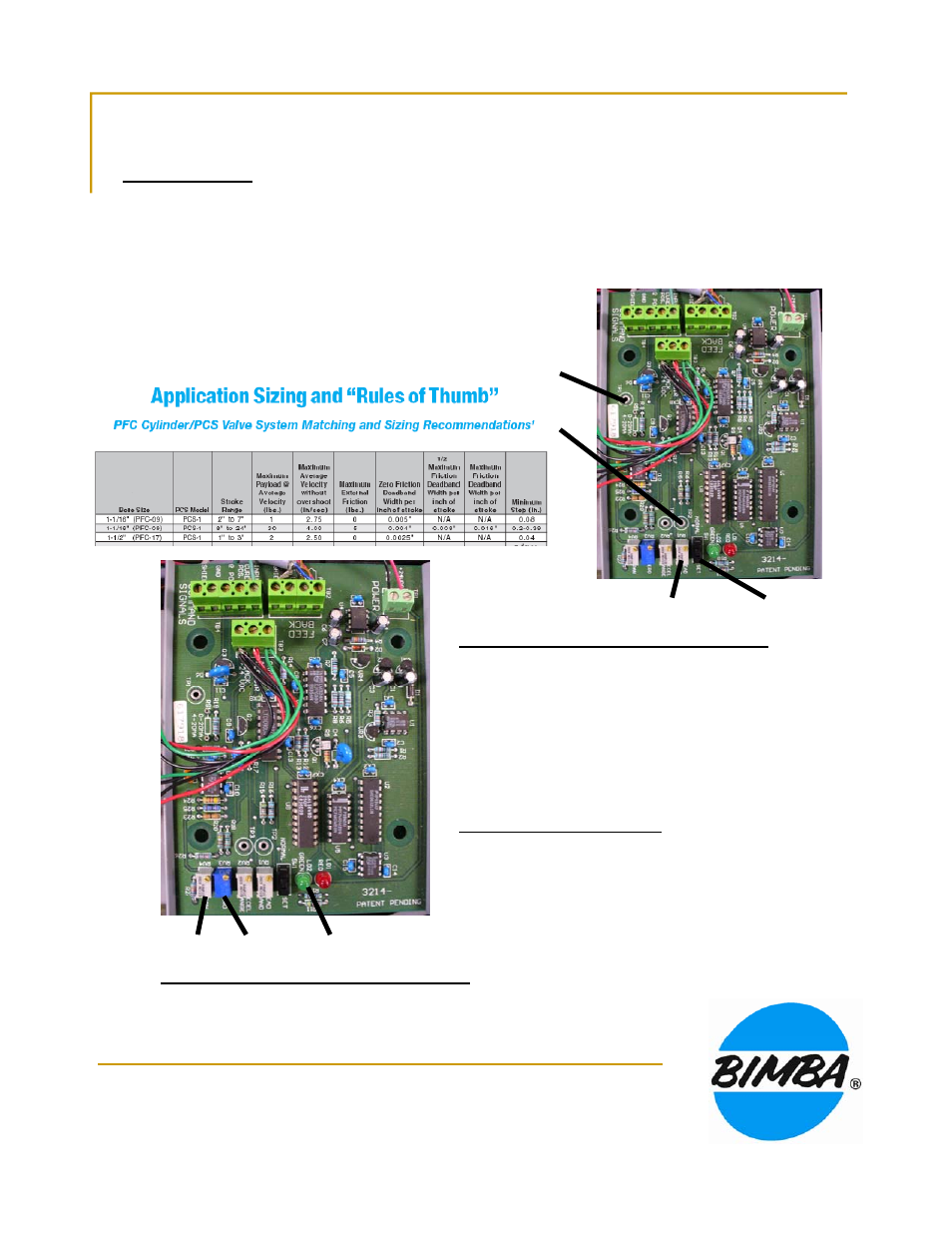

Locate TP1, TP2, SW 1, and the deadband adjustment pot.

3.

Move SW1 to SET position

4.

Set DMM to DC volts and measure between TP1 and TP2.

TP1

TP2

5.

Adjust deadband setscrew to 100 mV initially.

6.

Move SW1 to NORMAL position.

SW1

Deadband

Identify LEDs and Span and Zero adjustments.

LED’s indicate valve operation

1.

Green LED means rod is being extended: Air is

exhausted from Valve 1 (front) and pressure is applied

at valve 3 (rear)

2

Red LED means rod is being retracted: Air is

2.

Red LED means rod is being retracted: Air is

exhausted from Valve 3 (rear) and pressure is applied

at valve 1 (front).

Set the zero position (page 16)

1.

Set control voltage to 0.

2.

Turn ZERO adjust CW until rod is in the desired

retracted position (not necessarily fully retracted).

LED’s

Span

Zero

retracted position (not necessarily fully retracted).

3.

Red LED should not be on continuously.

Set the Span adjustment or end position (p.18)

1.

Set control voltage to maximum (10 VDC)

2.

Turn SPAN CCW until rod is in the desired fully extended position.

3.

The green LED should not be on continuously.