Off season storage, Choke adjustment, Off-season storage – Bolens 131-730A User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

To

Adjust

Carburetor—Turn

clockwise until it just closes.

needle valve

A

CAUTION

Valve may be damaged by turning it

in too far.

Now open needle valve 1 V

2

turns counterclock

wise. Close idle valve In the same manner and

open 1V2 turns. This initial adjustment will permit

the engine to be started and warmed up prior to

final adjustment. See figure 29.

To make the final adjustment, place governor con

trol lever in “FAST” position. Turn needle valve in

until engine slows (clockwise—lean mixture).

Then turn it out past smooth operating point (rich

mixture). Now turn needle valve to midpoint be

tween rich and lean. Next, adjust idle RPM. Rotate

throttle counterclockwise and hold against stop.

Adjust idle speed adjusting screw to obtain 1750

RPM. Holding throttle against idle stop, turn idle

valve in (lean) and out (rich). Set at midpoint be

tween rich and lean. Re-check idle RPM. Release

throttle. If engine will not accelerate properly, the

carburetor should be readjusted, usually to a

slightly richer mixture.

OFF SEASON STORAGE

If the machine is to be inoperative for a period

longer than 30 days, the following procedures are

recommended:

Working outdoors, drain all fuel from the fuel

tank. Use a clean dry cloth to absorb the small

amount of fuel remaining in the tank, then run

the engine until all fuel in the carburetor is ex

hausted.

2. Drain all the oil from the crankcase (this

should be done after the engine has been

operated and is still warm) and refill the

crankcase with clean new oil.

Disconnect the spark plug wires and remove

the spark plugs from the cylinders. Pour about

2 or 3 tablespoons of engine oil into each

cylinder, and then turn the engine over several

times to spread out the oil. Replace the spark

plugs but do not connect the wires.

4. Clean the engine and the entire tractor

thoroughly.

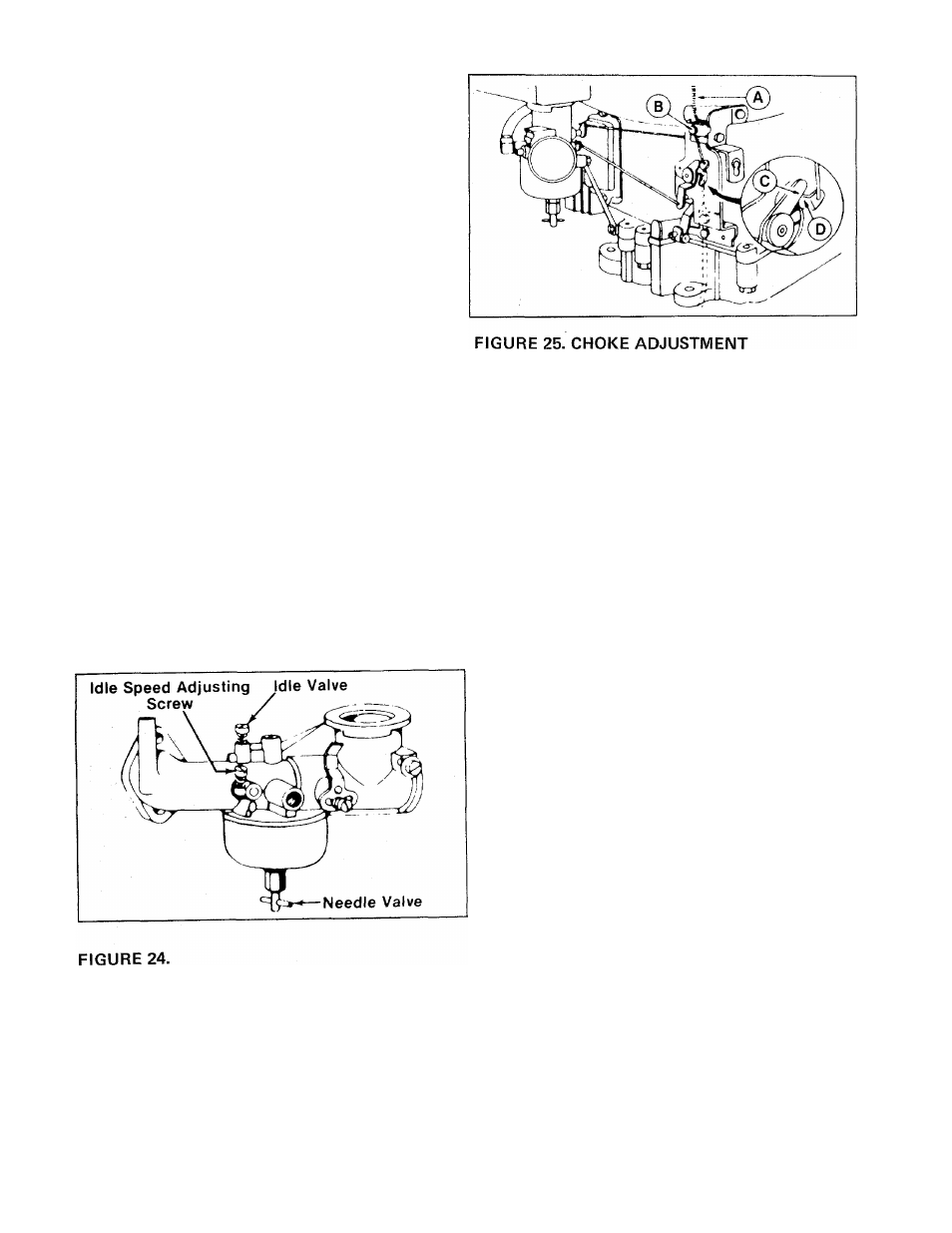

CHOKE ADJUSTMENT

Place control lever on equipment In “FAST” (high

speed) position. Loosen control casing clamp

screw B. Move control casing A and wire until

lever D touches choke operating link at C. Tighten

casing clamp screw B. See figure 25.

5. Lubricate all lubrication points and wipe the

entire machine with an oiled rag in order to

protect the surfaces.

6. Battery storage. See page 12.