Adjustment of blower speed, Color code for speed taps, Iv. care and maintenance – Bryant Gas Fired Forced Air 394 User Manual

Page 5: Cleaning, Care of blowers, Figure 4-flue-baffle retainer strip, Sc sex

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Adjustment of Blower Speed

Four-Speed Direct Drive

To change motor speed taps, remove the motor tap

lead (see Figure 1) and relocate it on the desired ter

minal on the plug-in terminal block/speed selector

located on the dividing panel. See Table I.

Belt Drive

The blower speed may be changed by opening or clos

ing the motor pulley. When adjusting blpwer speed,

be certain that both pulleys are adjusted the same

number of turns.

CAUTION: When adjusting the blower speed, make

certain that the temperature rise across the heat ex

changer does not exceed that specified on the rating

plate.

TABLE 1 - Factory Setting Blower Motor Chart

Unit

Size

Drive Type

SL

s

M

SE

SB

sc sex

Red

to

Blue

to*

Red

to

Blue

to

Red

to

Blue

to

Red

to

Red

to

Red

to

50

RI

4

1

4

1

80

3

1

4

1

100

2

1

4

1

1

1

1

125

3

1

3

1

1

1

1

137

2

1

2

1

1

1

1

165

2

1

1

1

190

1

1

1

220

1

1

*Use when relay kit is field installed.

Color Code for Speed Taps

Common (white)......................................................... #C Tap

Hi Speed (black).......................................................... #1 Tap

Med Speed (blue).........................................................#2 Tap

Med-To Speed (yellow)............................................... #3 Tap

Lo Speed (red)............................................................. #4 Tap

IV. CARE AND MAINTENANCE

Cleaning

The heat exchanger should be examined periodically

to see if there has been an accumulation of rust, soot,

etc. Clean as follows:

1. Disconnect pilot tubing at tube union.

2. Disconnect electrical lead from pilot. (In case of

100% shut-off controls, disconnect pilot thermocouple

lead from pilot relay or inline shut-off valve.)

3. Remove front plate from draft diverter (4 sheet-

metal screws).

4. Remove burners and pilot as follows:

a. Remove Tinnerman clamp from burner-holding

stud.

b. Slide burner off orifice and remove under

manifold.

c. Pilot is attached to one burner and is removed

with that burner. It is not necessary to detach

pilot before removing burner.

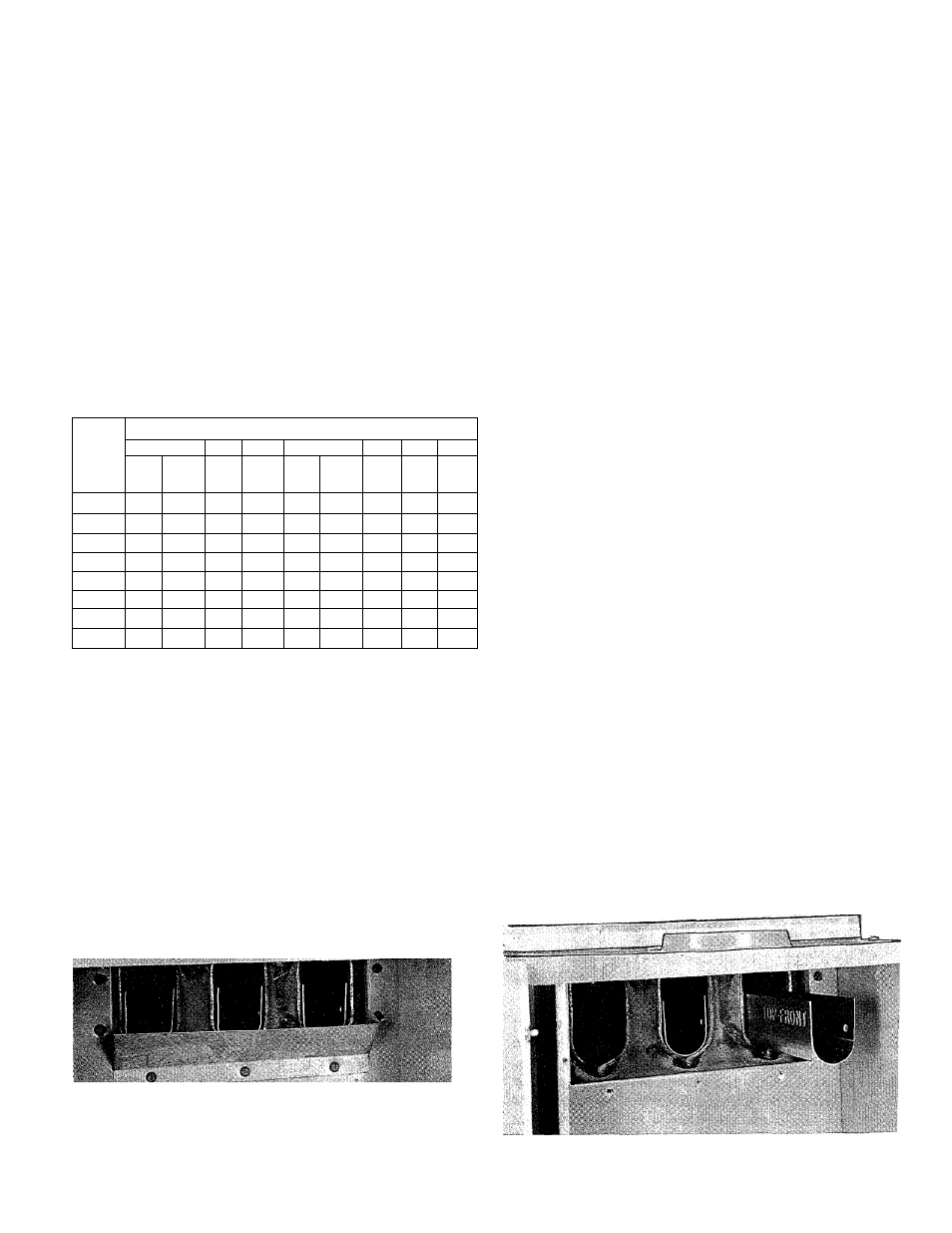

5. Remove metal angle strip holding flue baffles in

place. See Figure 4.

6. Remove flue baffles. See Figure 5.

7. Use flexible-handled steel cleaning brush to loosen

scale and soot. Remove scrapings from bottom of

combustion chamber.

combustion chamber.

8. Reassemble furnace by reversing above procedure.

NOTE: There is a slot in the back of the heat ex

changer for the back tip of the burner to fit into. When

properly placed, the burner will fit into this slot and

will be level.

Care of Blowers

All motors on the belt drive blowers are provided with

oil cups and should be oiled at least twice a year with

a nondetergent SAE 30 oil.

Figure 4-Flue-Baffle Retainer Strip

Figure 5-Removing Baffles

39394D41