Gas piping – Bryant Gas Air 393U User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

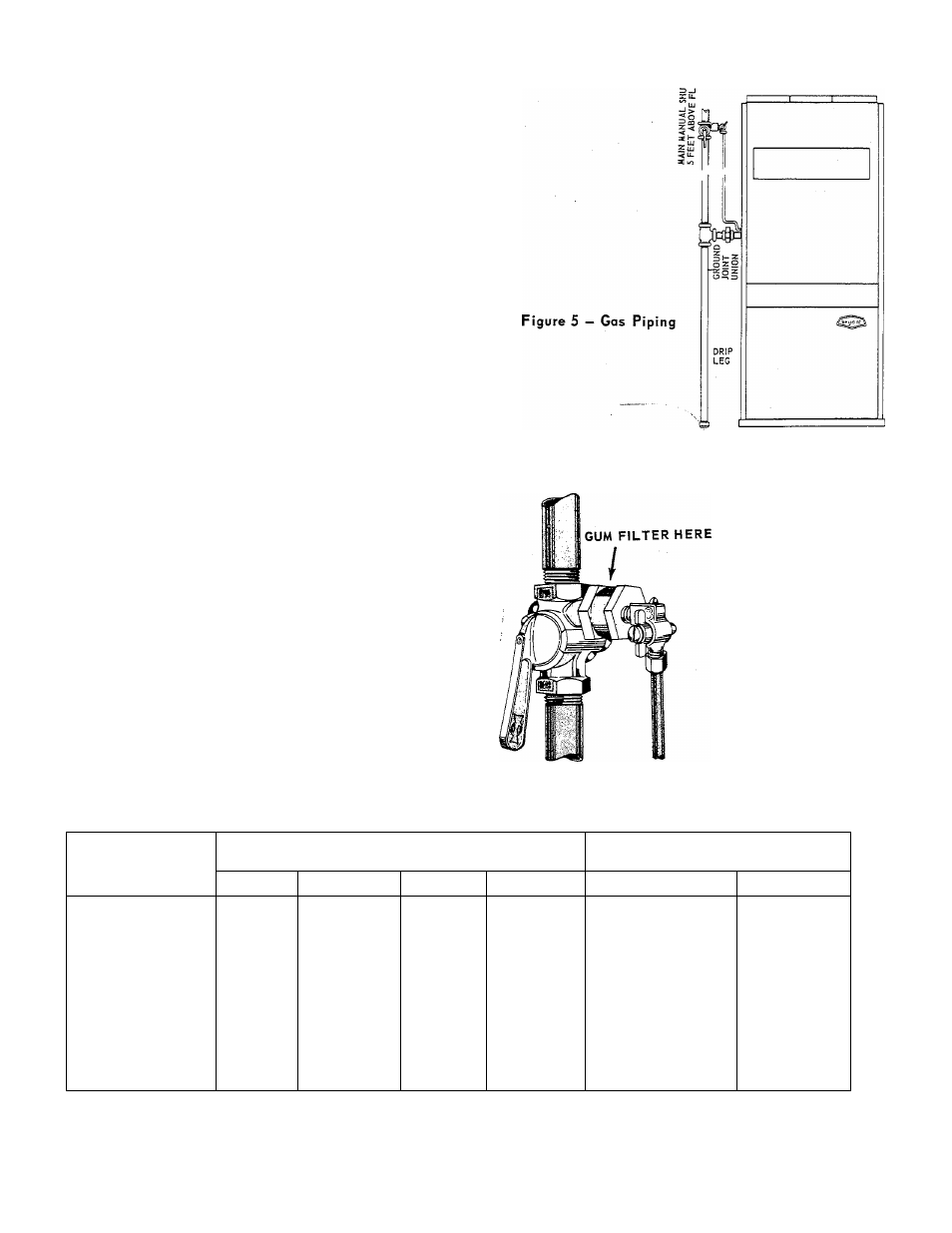

GAS PIPING

The gas supply line should be a separate line direct

from the meter to the furnace. Check local utility for

recommendations concerning existing lines. Choose

a supply pipe size large enough to keep the pres

sure loss as low as practicable. The supply pipe

should never be smaller than the inlet to the gas

valve. For pipe capacities at 0.3 inches w.c. pres

sure drop, see Iron Pipe Capacity table below.

Observe local codes for all gas pipe installation.

The following are pertinent recommendations:

1. Avoid low spots in long runs of pipe. These low

spots may trap water in the supply line. It is best

to slope all pipe 1/4 inch in 15 feet to prevent

traps. All horizontal runs should slope to risers.

Risers should be used to connect to the furnace and

to the meter.

2.

Install a drip leg in the riser leading to the

furnace. This drip leg will serve as a trap for dirt

or condensate.

This drip leg can be installed by connecting a TEE

to the riser leading to the furnace, so that the

straight-through section of the TEE is vertical.

Then connect a capped nipple to this TEE. The

capped nipple should extend below the level of the

gas controls, with the cap resting on the floor.

3. Install the main manual gas shut-off valve in the

supply line five feet above the floor. Install the

valve (supplied) so that the pilot manual cock is on

the inlet side of the valve. (See Figure 5.)

Figure 6

IRON PIPE CAPACITY (See Notes 1 & 2)

Length of Pipe

in Feet

Pipe Capacity in Cubic Feet Per Hour

for Diameters Shown

Multiplier to Use

for Different Specific Gravity

1/2"

3/4"

1"

1-1/4"

Specific Gravity

Multiplier

15

76

172

345

750

.35

1.31

30

52

120

241

535

.40

1.23

45

43

99

199

435

.45

1.16

60

38

86

173

380

.50

1.10

75

77

155

345

.55

1.04

90

70

141

310

.60

1.00

105

65

131

285

.65

.962

120

120

270

.70

.926

150

109

242

180

100

225

1. All values shown are based on a pressure drop of 0.3" w.c. and using gas with a specific gravity value

of 0.60 Consult local utility for local variations.

2. To convert to capacities for gas of different specific gravity, multiply the capacity values by the multi

pliers shown at the extreme right on table.

393U

- 6 -