Carrier 38BYG User Manual

Page 5

Use furnace transformer, fan coil transformer, or accessory trans-

former for control power, 24v/40va minimum.

NOTE:

Use of available 24v accessories may exceed the mini-

mum 40va power requirement. Determine total transformer load-

ing and increase the transformer capacity or split the load with an

accessory transformer as required.

IMPORTANT:

Check factory wiring and wire connections to

ensure terminations are secured properly. Check wire routing to

ensure wires are not in contact with tubing, sheet metal, and so

forth.

Step 11—Compressor Crankcase Heater

When equipped with a crankcase heater, furnish power to heater a

minimum of 24 hr before starting unit. To furnish power to heater

only, set thermostat to OFF and close electrical disconnect to

outdoor unit. A crankcase heater is required if refrigerant tubing is

longer than 50 ft.

Step 12—Install Electrical Accessories

Refer to the individual instructions packaged with kits or acces-

sories when installing.

Step 13—Start-Up

To prevent compressor damage or personal injury, observe

the following:

•Do not overcharge system with refrigerant.

•Do not operate unit in a vacuum or at negative pressure.

•Do not disable low-pressure switch.

In scroll compressor applications:

•Dome temperatures may be hot.

To prevent personal injury wear safety glasses, protective

clothing, and gloves when handling refrigerant and observe

the following:

•Back-seating service valves are not equipped with Schrader

valves. Fully back seat (counterclockwise) valve stem before

removing gage-port cap.

•Front-seating service valves are equipped with Schrader

valves.

Federal Regulations require that you do not vent refrigerant to

atmosphere. Recover during system repair or final unit

disposal.

Follow these steps to properly pumpdown a system and avoid

negative suction pressure.

1. Fully back seat (open) liquid- and vapor-tube service valves.

2. Unit is shipped with valve stem(s) front seated (closed) and

caps installed. Replace stem caps after system is opened to

refrigerant flow. Replace caps finger-tight and tighten with

wrench an additional 1/12 turn.

3. Close electrical disconnects to energize system.

Table 2—Accessory Usage

ACCESSORY

REQUIRED FOR

LOW-AMBIENT

APPLICATIONS

(BELOW 55°F)

REQUIRED FOR

LONG-LINE

APPLICATIONS*

(OVER 50 FT)

REQUIRED FOR

BURIED LINE

APPLICATIONS†

(OVER 3 FT)

Crankcase Heater

Yes

Yes

Yes

Evaporator Freeze Thermostat

Yes

No

No

Accumulator

No

No

Yes

Compressor Start-Assist

Capacitor and Relay

Yes

Yes

Yes

MotorMaster® Control,

or

Low-Ambient Pressure Switch

Yes

No

No

Wind Baffle

See low-ambient

Instructions

No

No

Unit Risers

Recommended

No

No

Liquid-Line Solenoid Valve

or

Hard-Shutoff TXV

No

See Long-Line

Application

Guideline

Yes

Ball-Bearing Fan Motor

Yes‡

No

No

* For tubing line sets between 50 and 175 ft, refer to Application Guideline and Service Manual — Air Conditioners and Heat Pumps.

† For buried line applications, refer to Application Guideline and Service Manual — Air Conditioners and Heat Pumps.

‡ Required for low-ambient controller (full-modulation feature) and MotorMaster® Control only.

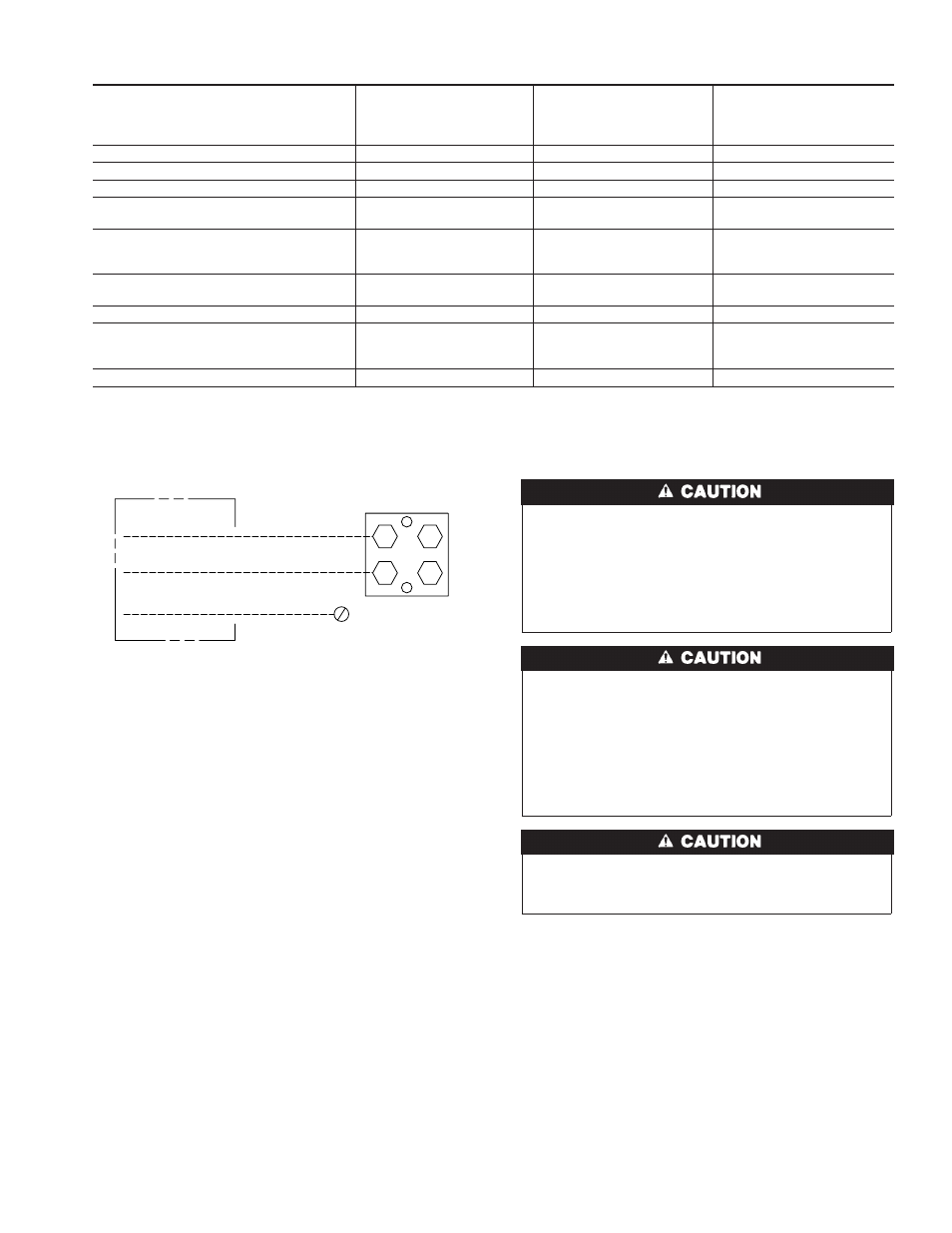

Fig. 8—Line Power Connections

A91056

DISCONNECT

PER N. E. C. AND/OR

LOCAL CODES

CONTACTOR

GROUND

LUG

FIELD GROUND

WIRING

FIELD POWER

WIRING

5