Carrier 38BYG User Manual

Page 2

INSTALLATION

Step 1—Check Equipment and Job Site

UNPACK UNIT

Move to final location. Remove carton, taking care not to damage

unit.

INSPECT EQUIPMENT

File claim with shipping company prior to installation if shipment

is damaged or incomplete. Locate unit rating plate on unit service

panel. It contains information needed to properly install unit.

Check rating plate to be sure unit matches job specifications.

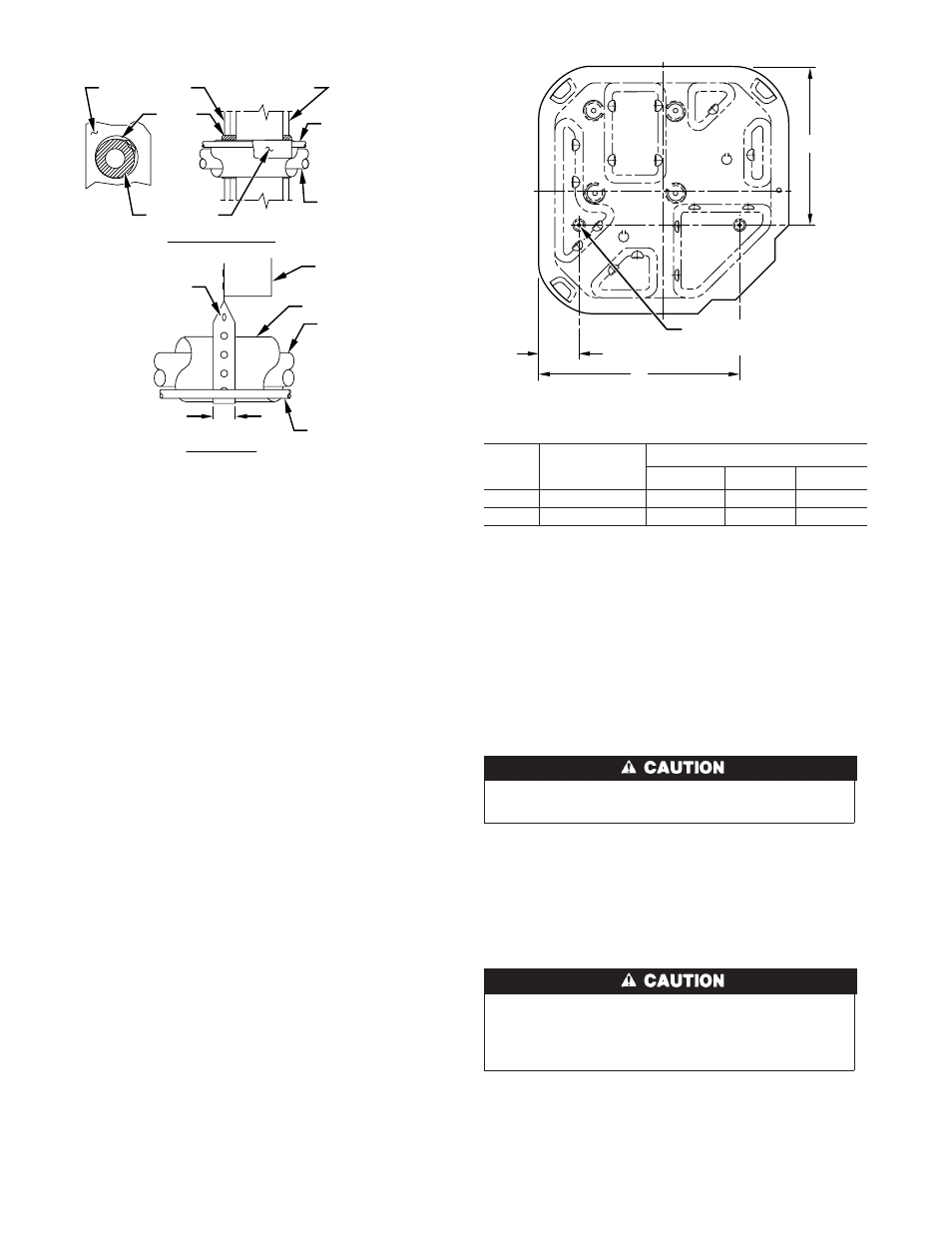

Step 2—Install On A Solid, Level Mounting Pad

If conditions or local codes require the unit be attached to pad,

tiedown bolts should be used and fastened through knockouts

provided in unit base pan. Refer to unit mounting pattern in Fig. 3

to determine base pan size and knockout hole location.

On rooftop applications, mount on level platform or frame. Place

unit above a load bearing wall and isolate unit and tubing set from

structure. Arrange supporting members to adequately support unit

and minimize transmission of vibration to building. Consult local

codes governing rooftop applications.

Roof mounted units exposed to winds above 5 mph may require

wind baffles to achieve adequate defrost. Consult Low Ambient

Guideline for wind baffle construction.

NOTE:

Unit must be level to within ± 2° (± 3/8 in./ft) per

compressor manufacturer specifications.

Step 3—Clearance Requirements

When installing, allow sufficient space for airflow clearance,

wiring, refrigerant piping, and service. Allow 30-in. clearance to

service end of unit and 48 in. above unit. For proper airflow, a 6-in.

clearance on 1 side of unit and 12 in. on all remaining sides must

be maintained. Maintain a distance of 24 in. between units.

Position so water, snow, or ice from roof or eaves cannot fall

directly on unit.

On rooftop applications, locate unit at least 6 in. above roof

surface.

Step 4—Operating Ambient

The minimum outdoor operating ambient in cooling mode is 55°F,

and the maximum outdoor operating ambient in cooling mode is

125°F. The maximum outdoor operating ambient in heating mode

is 66°F.

Step 5—Elevate Unit

Accumulation of water and ice in base pan may cause

equipment damage.

In areas where prolonged freezing temperatures are encountered,

elevate unit per local climate and code requirements to provide

clearance above estimated snowfall level and ensure adequate

drainage of unit.

Step 6—Remove Indoor AccuRater® Piston and Install

TXV

For proper unit operation and reliability, units must be

installed with field supplied hard shutoff TXV. Do not install

with evaporator coils having capillary tube metering devices

or pistons.

For TXV kit part number and charging instructions, refer to TXV

label in outdoor unit. If indoor unit (fan coil) comes factory

equipped with a bi-flow hard shutoff TXV, no TXV change is

required.

Fig. 2—Connecting Tubing Installation

A94028

INSULATION

VAPOR TUBE

LIQUID TUBE

OUTDOOR WALL

INDOOR WALL

LIQUID TUBE

VAPOR TUBE

INSULATION

CAULK

Avoid contact between tubing and structure

NOTE:

THROUGH THE WALL

HANGER STRAP

(AROUND VAPOR

TUBE ONLY)

JOIST

1

″

MIN.

SUSPENSION

Fig. 3—Mounting Unit to Pad

Dimensions (In.)

UNIT

SIZE

MINIMUM

MOUNTING-PAD

DIMENSIONS

TIEDOWN KNOCKOUT LOCATIONS

A

B

C

018-024

22-1/2 X 22-1/2

3-11/16

18-1/8

14-3/8

030-060

30 X 30

6-1/2

23-1/2

20

A94199

C

B

A

3

⁄

8

″

D. (9.53) TIEDOWN

KNOCKOUTS (2) PLACES

2