Wheel position, How to use your tiller – MTD 215-386-000 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HOW TO USE YOUR

TILLER

The gear shift lever is located on the top left hand

side of handle panel. There are four (4) forward

speeds, Neutral (N) and Reverse (R). Your tiller has

a variable speed pulley, which allows you to

change gears First (1) through Fourth (4) without

stopping.

A. Forward Speeds; First and second speeds are

generally used for tilling sod or soil which has

not been tilled before. Third and fourth speeds

are usually used for fine tilling or cultivating.

The soil conditions in your area will determine

the speed you will want to use. If you stop your

tiller or stall the engine while in a forward

speed, you

must

proceed as follows:

1. ) Remove the spark plug wire and ground on

engine block.

2. ) Pull the recoil starter rope, and at the same

time pull back on gear shift lever. Pull the

rope out as many times as it takes to move

the gear shift lever into neutral (N) position.

Do Not

force shift lever back into neutral at

any time.

3. ) Place the spark plug wire back on the spark

N

plug. Start your tiller.

4. ) Push down the handle so that the tines do

not touch the ground.

5. ) Move the gear shift lever through the for

ward speeds, neutral and reverse. Readjust

control rod if necessary.

B. Neutral (N); The neutral detent on the handle

panel is used when starting, stopping the tiiler

and going from a forward speed to reverse.

C. Reverse (R) Gear; The reverse gear is deadman

type. If you put the tiller into reverse to back

up, or to unclog the tines and you let go of gear

shift lever, the reverse motion will

stop.

Reverse will

only

work when you pull the gear

shift lever back and hold it in that position.

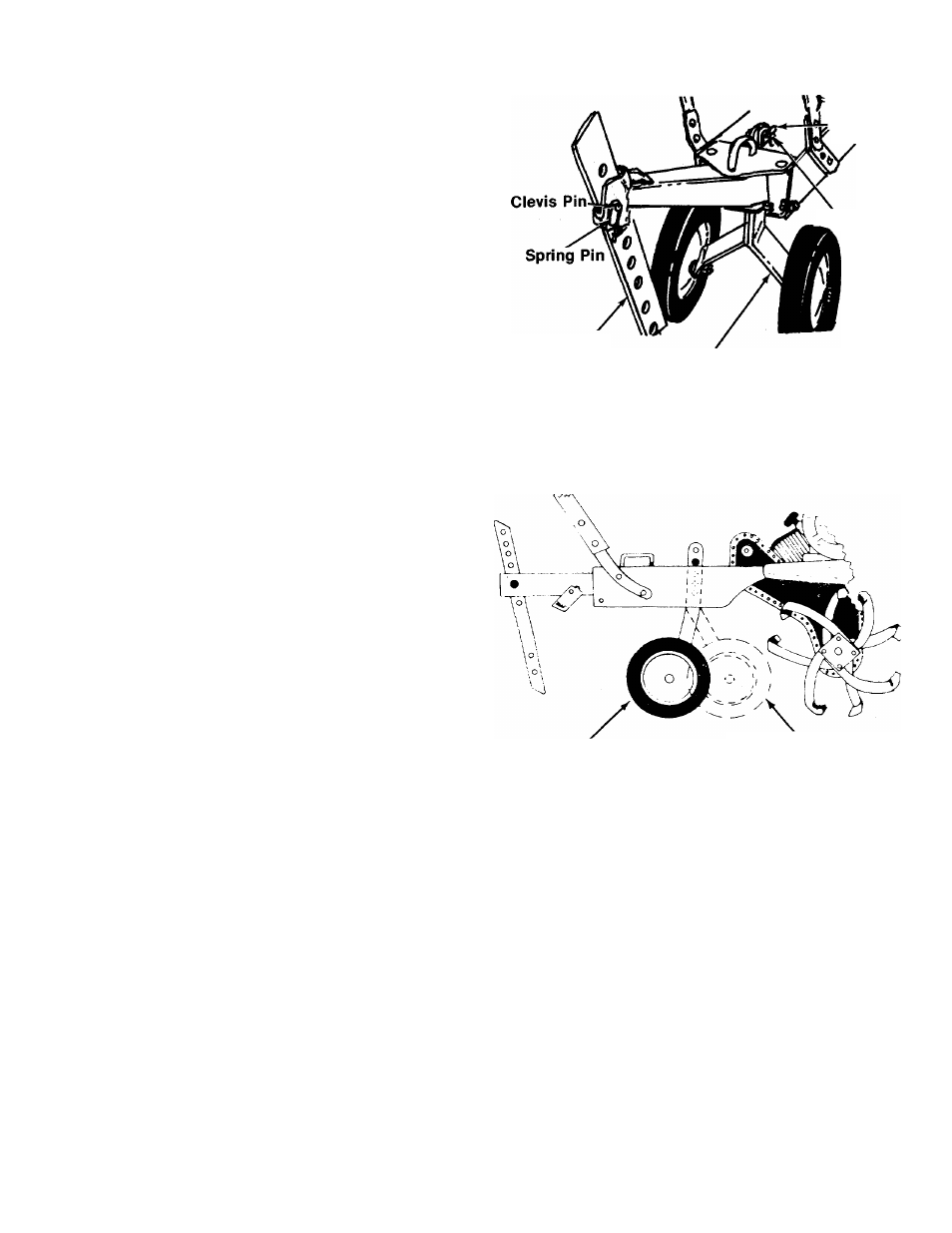

WHEEL POSITION

The tiller is shipped with the wheels adjusted

such that the unit sits level. During digging as the

tines enter the ground and the front of the tiller

lowers, the wheels must be raised to ievel the

unit. This is essential for proper engine operation.

This adjustment is made by removing the cievis

pin and hairpin cotter from wheel yoke, raising the

wheels to the desired height, and replacing the

clevis pin and hairpin cotter. See figure 15.

/

^Hairpin

Cotter

Clevis Pin

Depth Bar

Wheel Yoke

FIGURE 15.

CONTROLLING SPEED AND TILLING DEPTH

Wheel Yoke in

this position

for deep dig.

FIGURE 16.

Wheel Yoke in this

position for shallow

dig, cultivating and

transport.

1.

Wheel Yoke Adjustment:

Place wheel yoke so

that the wheels are forward (nearest point be

tween wheels and tines) for shallow tilling,

cultivating and transport. This will increase

the forward speed. See figure 15. Turn yoke

around (farthest point between wheels and

tines) for deep tilling. Forward speed will

decrease. See figure 16.

2. Depth Bar Adjustment:

The depth bar acts as

a brake for the tiller and controls the depth

and speed at which the machine will operate.

See figure 17. Remove the clevis pin and

spring pin to raise or lower depth bar.